Check high pressure hose, Check gun and nozzle extension, Check in-line filter – Craftsman 580.752000 User Manual

Page 12: Nozzle maintenance, Purge pump of air and contaminants, Vmrnino

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Check High Pressure Hose

High pressure hoses can develop leaks from wear,

kinl

damage or movement of couplings. If any of these

conditions exist, repiace hose immediateiy.

^ VMRNINO

The high pressure stream of water that this

equipment produces can pierce skin and its

underlying tissues, leading to serious Injury

and possible amputation.

NEVERTepair highlpfessuredlose; ReplaoeliT 111

Replaoement hose ratir^ MUST exceedmaximurTT

pressure rating: of onit; 1 1 1 1 : : : : : : : : : : : : : : : : : : : : : : : : : : : : : t

Check Gun and Nozzle Extension

Examine hose connection to gun and make sure it is

secure. Test trigger by pressing it and making sure it

springs back into place when you release it. Engage

safety latch and test trigger. You should not be able to

press trigger. Replace gun immediately if it fails any of

these tests.

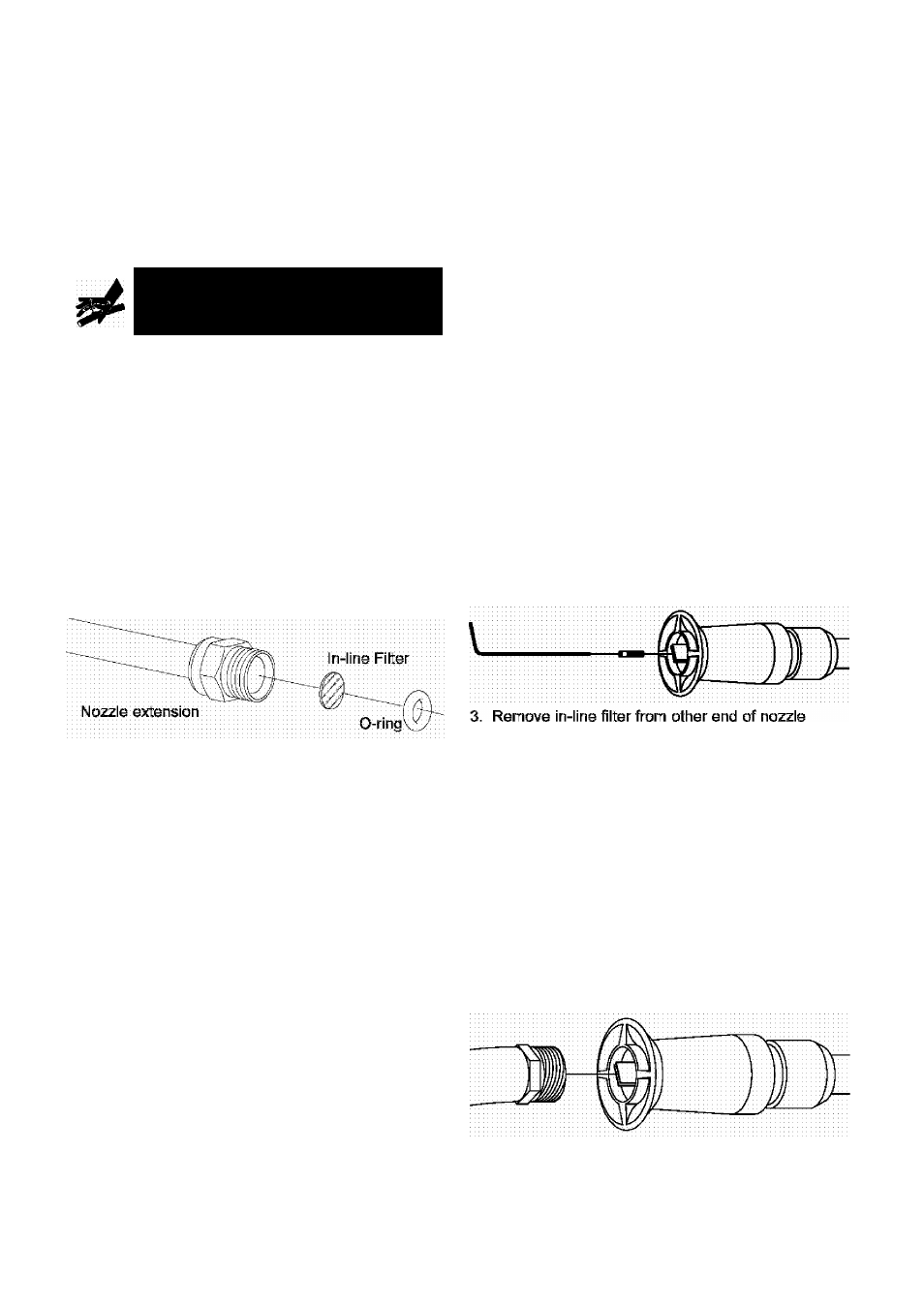

Check In-Line Filter

Refer to the illustration and service the in-line filter if it

becomes clogged, as follows:

To remove contaminants from the pump, follow these

steps:

1. Set up pressure washer as described in

“Assembling Your Pressure Washer' section, and

connect water supply.

2.

Remove nozzle extension from gun.

3. Start engine acœrding to instructions in “How To

Use Your Pressure Washer” section.

4.

Pull trigger on gun and hold.

5. When water supply is steady and constant, engage

safety latch and refasten nozzle extension.

Nozzle Maintenance

A pulsing sensation felt while squeezing the spray gun

trigger may be caused by excessive pump pressure.

The principal cause of excessive pump pressure is a

nozzle clogged or restricted with foreign materials,

such as dirt, etc. To correct the problem, immediately

clean the nozzle following these instructions:

1. Shut off engine and turn off water supply.

2. Remove nozzle from end of nozzle extension.

Separate nozzle extension from spray gun. Twist

nozzle clockwise to stream position. Using a 2mm

(5/64) alien wrench, remove orifice from end of

nozzle extension.

1. Detach nozzle extension from gun and remove

o-ring and screen from nozzle extension. Flush

screen, gun, and nozzle extension with clean water

to clear debris.

2. Place in-line filter screen into threaded end of

nozzle extension. Direction does not matter. Push

screen in with eraser end of pencil until it rests flat

at bottom of opening. Take care not to bend

screen.

3. Place o-ring into recess. Push o-ring snugly against

in-line filter screen.

4. Assemble nozzle extension to spray gun, as

described earlier in manual.

Purge Pump of Air and Contaminants

To remove air from the pump, follow these stef:^:

1. Set up pressure washer as described in

“Assembling Your Pressure Washer' section and

connect water supply.

2.

Pull trigger on gun and hold until a steady stream

of water appears.

extension.

Use a small paper clip to free any foreign material

clogging or restricting orifice.

Inser: wire into orifice and turn cack

..... and forth to clear obstruction..............

5. Using a garden hose, remove additional debris by

back flushing water through nozzle extension. Back

flush between 30 to 60 seconds. Turn adjustable

nozzle extension to stream spray and move nozzle

from low to high while fiushing.

12