Maintenance – Craftsman 875.199810 User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Owner’s Manual

Model No. 875.199810

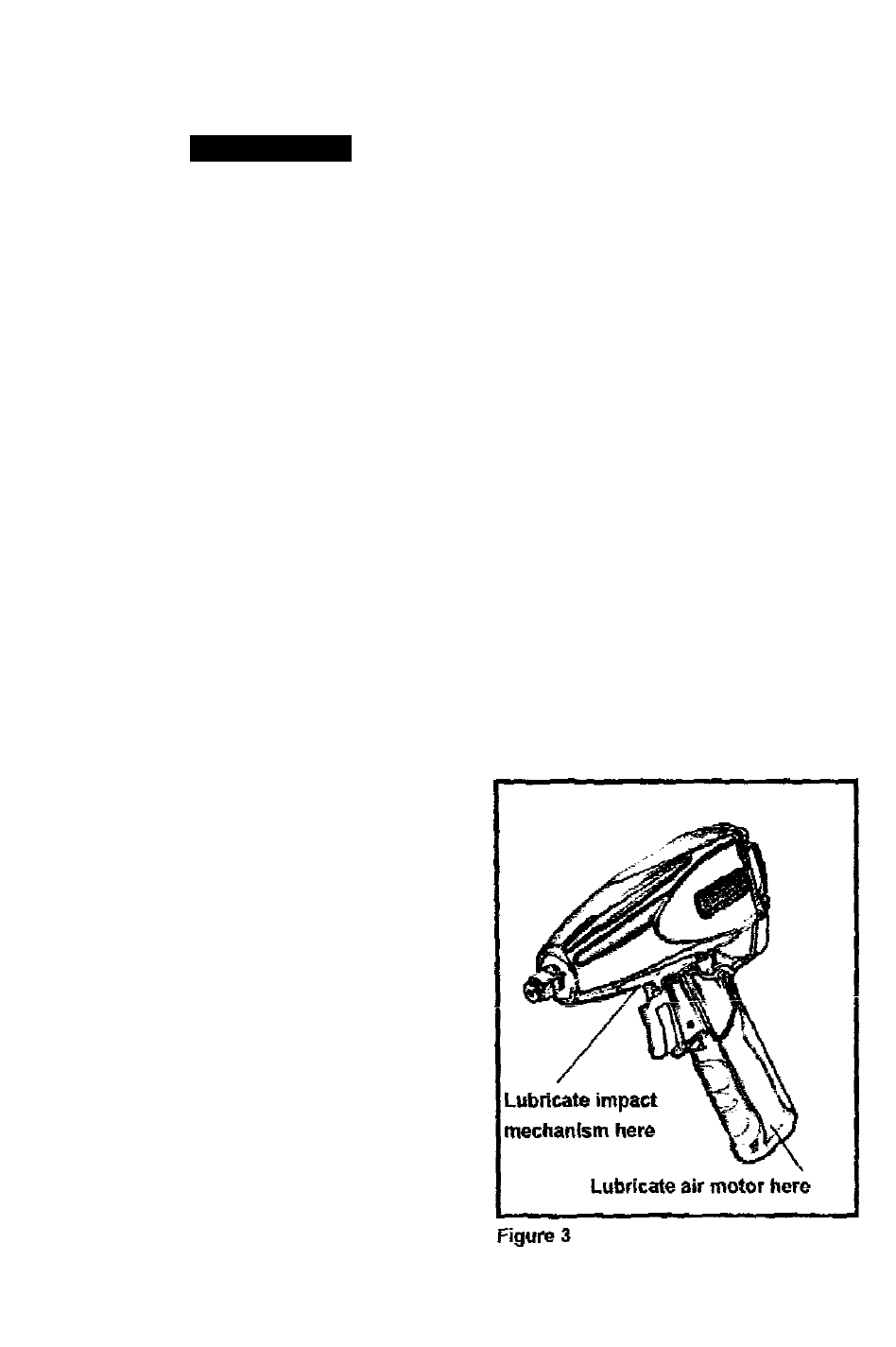

Maintenance

Excessive amounts of off should be

avoided. In the event that it becomes

necessaty to store the tool for an

extended period of time {overnight,

v№ekend, etc.), it should receive a

generous amount of lubrication through

the air inlet (Figure 3). The tool should be

run for approximately 30 seconds to

ensure oil has been evenly distributed

throughout the tool. The tool should be

stored in a clean and dry environment.

Recommended Lubricants

Use air looi oil or any other high grade

turbine oil containing moisture absorbent,

rust inhOtitors, metal wetling agents and

an EP (extreme pressure) additive. See

Figure 3 for localion/air inief.

IMPACT MECHANISM LUBRICATION

The in^iact mechanism transfers power

from the tool to a nul or bolt. Oil in the

merltanism is forced out and must be

replaced. Lubricate the impact

mechanism one time a yean more

often If a tool Is used more than ten

hours a week.

To lubricate and clean the impact

mechanism and the front bearing:

1.Disconnect the impact wrench from

the air supply.

Lubrication

An in-line filter-regulator-lubricator (fig 1)

is recommended as it increases tool Bfe

and keeps the tool in sustained operation.

The in-line lubricator should be regularly

checked and filled with air tool oil. Proper

adjustment of the in-line lubricator is

performed by pladng a sheet of paper

next to the tools exhaust ports and holding

the throttle open approximately 30

seconds. The lubricator "is properly set

when a light stain of oil coSecfs on the

paper.

2.

Remove the slotted screw or Allen

head screw from the oil port hole

(Ref. No. 51) (Referto figure 3).

3.

Squeeze approximately 1 oz. of 30 weight oil

through the oil port hole. Replace the screw.

4.

Reconnect the ar supply to the Impact

wrench and run for 20 to 30 seconds.

Lubricate the entire impact mechanism

by rotating the tool upside down

and sideways while running the toot.

5.

Remove the screw and hold the oil

port hole over a suitable container to

allow excess oil to drain. Sometimes

triggering the tool when dumping the oils

helps to force out the excess oil.

6. If the oil is dirty, repeat the procedureabove

until the oil comes out dear. Install the screw

and tighten. The residual oil remaining in the

impact mechanism chamber is all that is

needed for proper lubrication.

ENG-e