Caution, Check and clean inlet screen, Check high pressure hose – Craftsman 580.752010 User Manual

Page 14: Check gyn and nozzle extension, Check in-line filter, Nozzle maintenance, O-ring maintenance, 4 warning, Warning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Pressure washer parts should be kept clean to reduce the

risk of overheating and ignition of accumulated debris.

CAUTION

m

Improper treatment of

damage it and shorter

DO NOT insert any objects through cooling slots.

• Use a damp cloth to wipe exterior surfaces clean.

• Use a soft bristle brush to loosen caked on dirt, oil,

etc.

• Use a vacuum cleaner to pick up loose dirt and debris.

• Use low pressure air (not to exceed 25 psi) to blow

away dirt. Inspect cooling air slots and openings on

the pressure washer. These openings must be kept

clean and unobstructed.

Check and Clean inlet Screen

Examine garden hose inlet screen. Clean if it is

clogged or replace if it is torn.

Check High Pressure Hose

High pressure hoses can develop leaks from wear,

kinking, or abuse. Inspect hose before each use.

Check for cuts, leaks, abrasions, bulging of cover, or

damage or movement of couplings. If any of these

conditions exist, replace hose immediately.

^ WARNING

The high pressure stre

equipment produces c

underlying tissues, lea

and possible amputatii

NEVER

repair high

pressure

hose.

Replace

if.

Replacement

hose rating MUST exceed

maximum

pressure rating of

unit.

Check Gyn and Nozzle Extension

Examine hose connection to gun and make sure it is

secure. Test trigger by pressing it and making sure it

springs back into place when you release it. Engage

trigger lock and test trigger. You should not be able to

press trigger. Replace gun immediately if it fails any of

these tests.

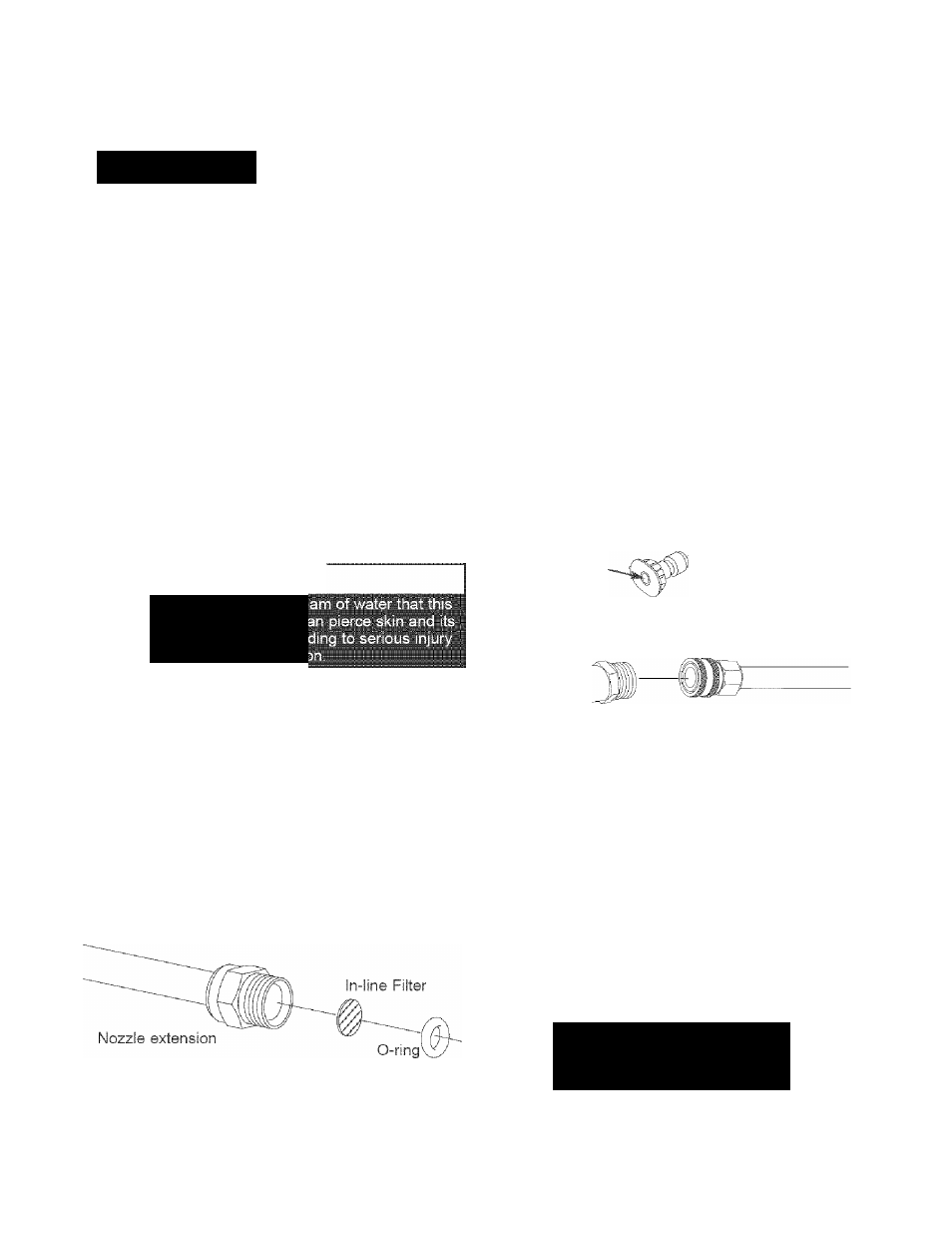

Check In-Line Filter

Refer to the illustration and service the in-line filter if it

becomes dogged, as follows:

1. Detach nozzle extension from gun and remove

o-ring and screen from nozzle extension. Flush

screen, gun, and nozzle extension with clean water

to clear debris.

2. Place in-line filter screen into threaded end of

nozzle extension. Direction does not matter. Push

screen in with eraser end of pencil until it rests flat

at bottom of opening. Take care not to bend screen.

3. Place o-ring into recess. Push o-ring snugly against

in-line filter screen.

4. Assemble nozzle extension to spray gun, as

described earlier in manual.

Nozzle Maintenance

A pulsing sensation felt while squeezing the spray gun

trigger may be caused by excessive pump pressure.

The principal cause of excessive pump pressure is a

spray tip clogged or restricted with foreign materials,

such as dirt, etc. To correct the problem, immediately

clean the spray tip following these instructions:

1. Shut off engine and turn off water supply.

2. Remove spray tip from end of nozzle extension.

3. Remove in-line filter from other end of nozzle

extension.

4. Use a small paper clip to free any foreign material

clogging or restricting spray tip.

Use wire here to

remove debris.

Using a garden hose, remove additional debris by

back flushing water through nozzle extension.

Back flush between 30 to 60 seconds.

6. Reinstall spray tip and in-line filter into nozzle

extension.

7. Reconnect nozzle extension to spray gun.

8. Reconnect water supply, turn on water, and start

engine.

9. Test pressure washer by operating with each

quick connect spray tips.

O-Ring Maintenance

Purchase an 0-Ring Repair Kit at your local Sears or by

calling 1 ^00-366-PART or online at . It is

not included with the pressure washer. This kit includes

replacement o-rings, rubber washer and water inlet filter.

Refer to the instruction sheet provided in the kit to service

your unit’s o-rings.

4 WARNING

igh pressure stream oTwate

ment produces can pierce s

underlying tissues, leading to seri

and possible amputation.

NEVER repair leaking connections with sealant of any

kind.

Replace

o-ring or seal.

14