Engine speed, Tires – Craftsman 247.346250 User Manual

Page 17

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

NOTE: A dirty air cleaner will cause engine to run

rough. Be certain air cleaner is clean and attached to

the carburetor before adjusting carburetor. Do not

make unnecessary adjustments. Factory settings are

satisfactory for most applications and conditions.

Never attempt to change maximum engine speed. It is

pre-set at the factory and should be changed only by

a qualified service technician who has the necessary

equipment.

The carburetor may need re-adjusting if engine lacks

power or does not idle properly. If adjustments are

needed, proceed as follows,

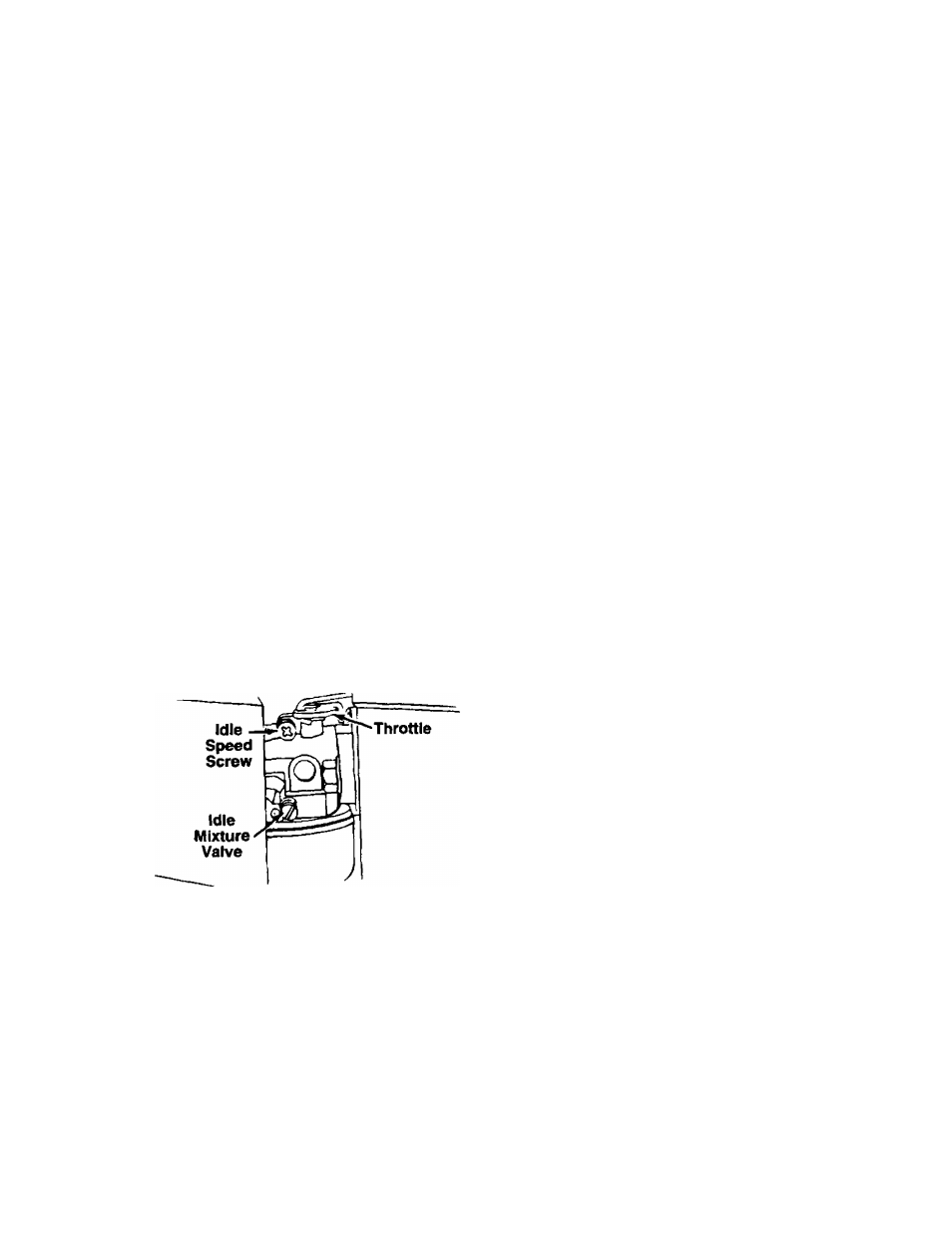

• Close idle mixture valve (see figure 21) clockwise

() finger tight only. Forcing may cause damage.

Then open 1 -1/2 turns counterclockwise ().

• Start engine and allow to warm for five minutes.

• Move throttle control lever to IDLE position.

•

Rotate throttle counterclockwise (^ ) and hold

against idle speed adjusting screw. Turn idle speed

adjusting screw until engine is running at 1750

RPM.

• Turn idle mixture valve clockwise ) (lean mix

ture) until engine JUST starts to slow. Then turn it

counterclockwise (^) (rich mixture) until engine

starts to run unevenly. Set at midpoint between rich

and lean mixture.

• Recheck idle RPM and readjust if necessary.

•

Move throttle control lever to FAST position.

Engine should accelerate without hesitation or

sputtering. If it does not, carburetor should be read

justed, usually to a slightly richer mixture.

ENGINE SPEED

Your engine speed has been factory set. Do not

attempt to increase engine speed or it may result in

personal injury. If you believe the engine is running

too fast or too slow, take your log splitter to the

nearest SEARS Service Center for repair and adjust

ment.

TIRES

Recommended operating tire pressure is 12 to 15

p.s.i. (sidewall of tire may give tire manufacturer's rec

ommended pressure). Maximum tire pressure under

any circumstances is 30 p.s.i. Equal tire pressure

should be maintained on all tires.

When installing a tire to the rim, be certain rim is

clean and free of rust. Lubricate both the tire and rim

generously. Never Inflate to over 30 p.s.i. to seat

beads.

A

WARNING:

EXCESSIVE

PRESSURE

(OVER 30 p,s.{.) WHEN SEATING BEADS

MAY CAUSE TIRE/RIM ASSEMBLY TO

BURST WITH FORCE SUFFICIENT TO

CAUSE SERIOUS INJURY.

FIGURE 21.

17