Weather hood type, Recommended, Use only for short run installations – LG TD-V12246E User Manual

Page 23: Exhaust requirements and instructions, Watermark si, Exhaust requirements and maintenance

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

EXHAUST REQUIREMENTS AND MAINTENANCE

Following are important instructions and information concerning the exhaust requirements for your dryer,

A. Warning; DO NOT exhaust dryer air into an enclosed and unventilated area, such as an attic, wall, ceiling,

crawl space, chimney, gas vent, or concealed space of a building. To reduce the risk of fire, DO NOT exhaust the

dryer with plastic or thin foil Ducting, Failure to do so can result in death, explosion, or fire.

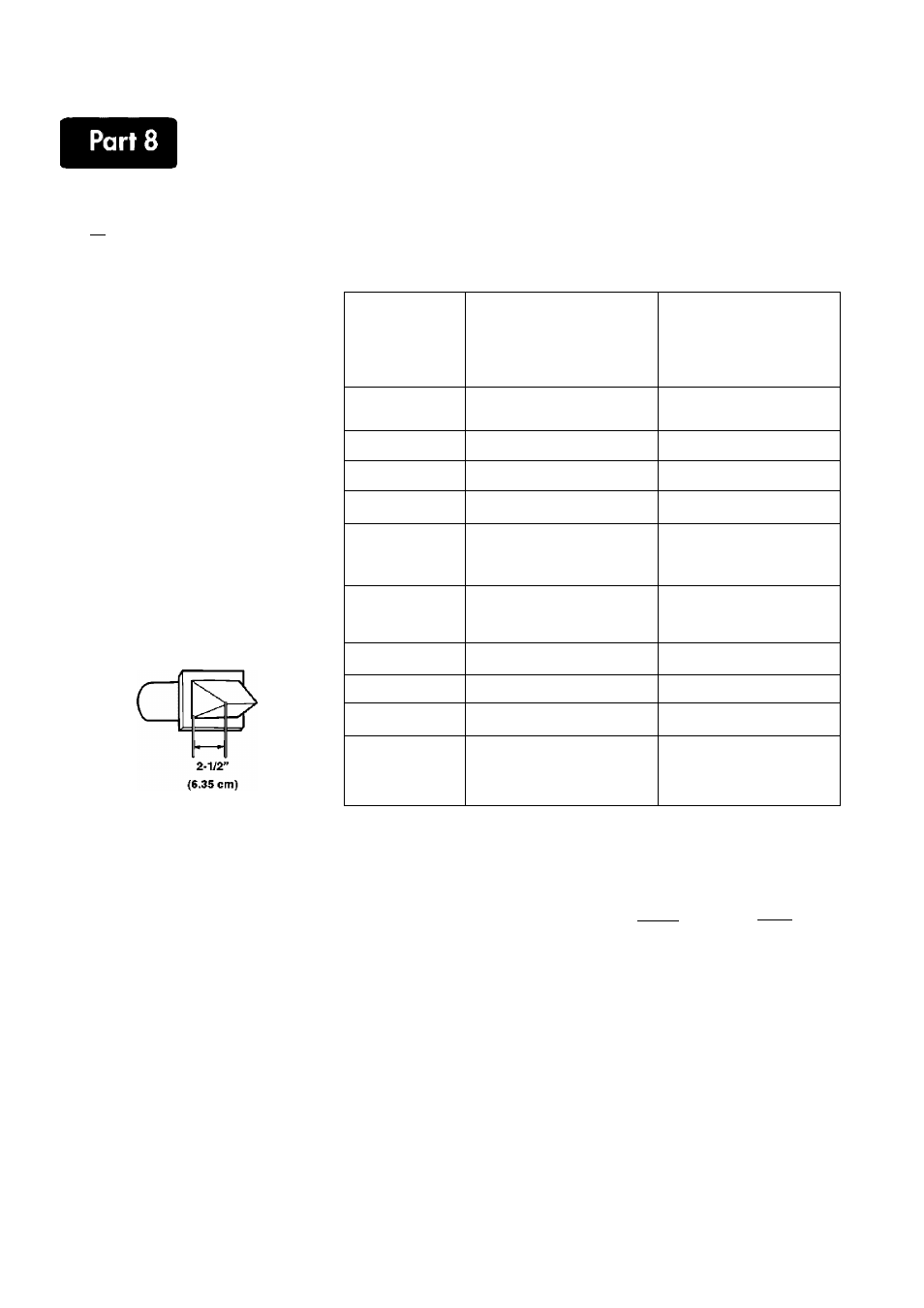

Weather Hood

Type

Number of 90°

Elbows

Maximum length of 4”

(10.2 cm) diameter rigid

metal duct

Maximum length of 4”

(10.2 cm) diameter

flexible metal duct

0

65 feet (19.8 m)

45 feet (13.7 m)

1

55 feet (16.8 m)

35 feet (10.7 m)

2

47 feet (14.3 m)

30 feet (9.1 ni)

3

36 feet (11.0m)

25 feet (7.6 m)

4

28 feet (8.5 m)

20 feet (6.1 m)

0

55 feet (16.8 m)

35 feet (10.7 ni)

1

47 feet (14.3 m)

27 feet (8.2 m)

2

41 feet (12.5 m)

21 feet (6.4 m)

3

30 feet (9,1 m)

17 feet (5.2 m)

4

22 feet (6,7 m)

15 feet (4.5m)

Recommended

Bd

4”

(

10.2

cm)

4"

(10.2 cm)

Use Only for Short Run

Installations

NOTE : Deduct 6 feet (1.8 m) for each additional elbow.

It is not recommended to use more than 4 90° elbows.

Exhaust Requirements and Instructions:

1. Venting materials are not provided with the dryer

and you should obtain the necessary venting

materials locally. For example, the outer end of

exhaust pipe must have a weather hood with hinged

dampers to prevent back-draft when the dryer is not

in use.

2. The exhaust duct must be four inches (10.2 cm) in

diameter with no obstructions. The exhaust duct

should be kept as short as possible. Make sure to

clean any old ducts before installing your new dryer.

3. Rigid or semi-rigid metal di

for use as transition ^ITteti

and the wall.

i mpos sibleto^^P^^^ei

recomin^telfflisfir

transitioiiBfft,

wall

affeef

ins IS ^commended

^ oan^r and

a UL-listed flexibli

be used between the dryer

' use sheet mcj

I other fastenin^if

[that could catclftlj

Ly of the exliail

t pipe

I into

r joints

5. To n]

duct lenaj

WATERMARK Si

Itec^^fratmg results, please observe theOJ

ii^jtipns noted in the chart above.^