Taylor-Wharton EF-1000 User Manual

Page 9

BT-472 Rev. B

9

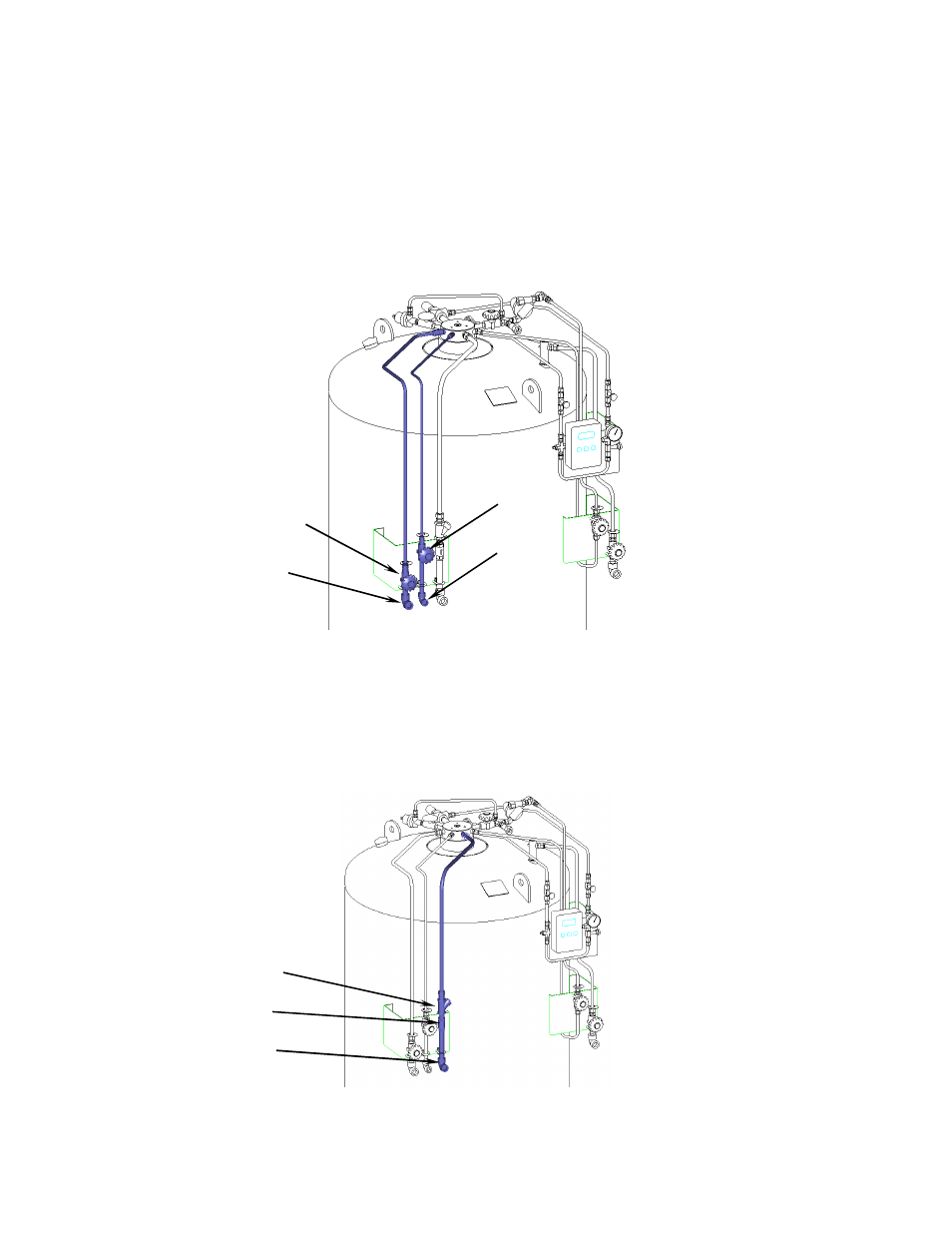

Fill and Vent Circuits

The liquid valve (V-1) communicates with the bottom of the vessel. A stainless steel tag labeled “LIQUID” identifies

the valve and the liquid connection (CN-1). Liquid is added or removed from the vessel through this connection and

valve.

The vent / trycock valve (V-2) is attached to a vertical tube in the upper portion of the vessel. The open end of the tube

is positioned at 90% liquid level based on the vessel volume. Opening the vent valve reduces pressure in the vessel

during filling. It also severs as a “full trycock”, venting liquid from the vessel when the liquid level exceeds 90%. A tag

labeled “VENT” is attached to this valve.

Figure 2: Fill and vent circuits highlighted in blue.

Express Fill Circuit

The Express Fill circuit may be used for filling from the Taylor-Wharton Express Cryogenic Delivery System or for top

filling by a cryogenic pump. Two check valves (CV-1 & CV-2) prevent product from escaping the vessel.

A fill stop valve (FSV-1) within the vessel prevents over filling. This device functions when filled by the Taylor-

Wharton Express Truck in automatic fill mode. The fill stop valve will not function when the vessel is filled by a typical

cryogenic pump.

Figure 3: Express Fill circuit highlighted in blue.

CV-1

CV-2 OR

V-1

CN-2

CN-1

V-2

CN-3

V-10