Wall mount for oscillating fan – Qmark LCHHD - Heavy Duty Oscillating Air Circulator User Manual

Page 3

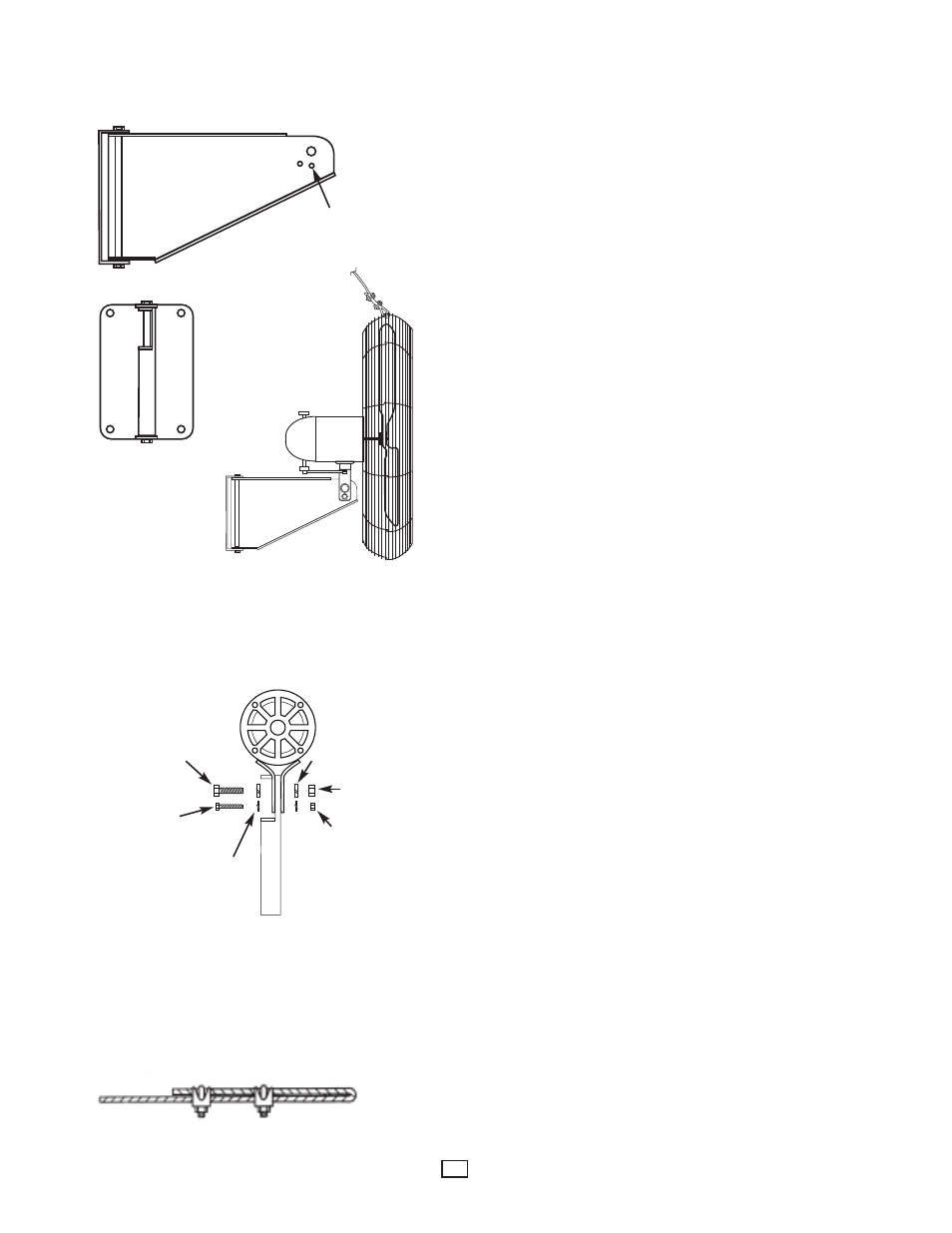

WALL MOUNT FOR OSCILLATING FAN

Figure 5

CAUTION: Do not install oscillating fans upside down as this may allow the fan

to fall or become permanently damaged. Mount only as shown in this manual

with the fan head on top of the bracket.

1. Securely mount the wall bracket directly to a cinder block wall or vertical I-beam.

Drill four 25/64” diameter holes in the proper locations on the mounting surface,

using the wall bracket as a template. 3/8-16 hex bolts are recommended for use

in mounting the bracket to the mounting surface. The bolts should be of suffi-

cient length for the particular surface to which the bracket is to be mounted. Also,

if mounting to a cinder block wall, large surface bearing washers are recom-

mended on the opposite side of the block to ensure the nut has sufficient surface

to be tightened. For installation on wood construction (minimum 2” x 4” stud),

secure bracket with heavy duty lag bolts or screws (not included). For concrete

or masonry installation use heavy duty expansion shields and lag screws (not

included). See Figure 5

NOTE: All installation should be done to meet local building codes.

2. Mount the motor assembly to the wall bracket using 1/2” x 1-1/2” hex bolt and

1/4” x 1-1/2” bolt, washers, lockwashers and hex nuts provided. See Figure 6

3. When mounting oscillating motor and fan assemblies, use only the 1/4” adjust-

ment hole directly below the 1/2” mounting hole on wall mount bracket. See

Figure 5.

NOTE: Use of the wrong hole on the wall bracket will cause the oscillating models

to tilt too much and will cause the oscillating mechanism to bind and cause pre-

mature failure.

4. DO NOT use an extension cord. For units which feature two part cordsets, con-

nect the male end of the motor cord to the female end of the cordset. Plug power

cord from fan into any 120 VAC 3 prong, grounded outlet.

SECONDARY SUPPORT CABLE INSTALLATION

For Overhead Wall Mounted Application

Loop secondary support cable around top of fan guard as indicated. Secure cable

making sure both front and back guards are inside loop but cable is not allowed to

touch fan blade (See Figure 5). Secure ends with two cable clamps, loop other end

of cable around any permanent sturdy structural member close to fan (rafter, I-

beam, joist, etc.) and secure ends with two cable clamps. Give enough slack such

that fan will be able to make its full sweep without the support cable restraining its

sweeping action.

IMPORTANT NOTICE: It is important to note the proper installation position of the

cable clamps as illustrated. To obtain maximum holding power, install U-bolt sec-

tion of clip on dead or short end of cable and saddle on long end of cable (See

Figure 7). Improper installation reduces the efficiency of the connection by as much

as 40 percent.

3

Oscillator motors use this

hole only for adjustment.

1/2-13 HHCS

Bolt

1/4-20 HHCS

Bolt

Lockwasher

Lockwasher

1/2-13 Hex Nut

1/4-20 Hex Nut

Figure 6

Figure 7