Helpful information, Page 11 – Pro-Tools MB-105 User Manual

Page 11

PAGE 11

QUALITY PRODUCTS BY PEOPLE WHO CARE

(813) 986-9000

HELPFUL INFORMATION

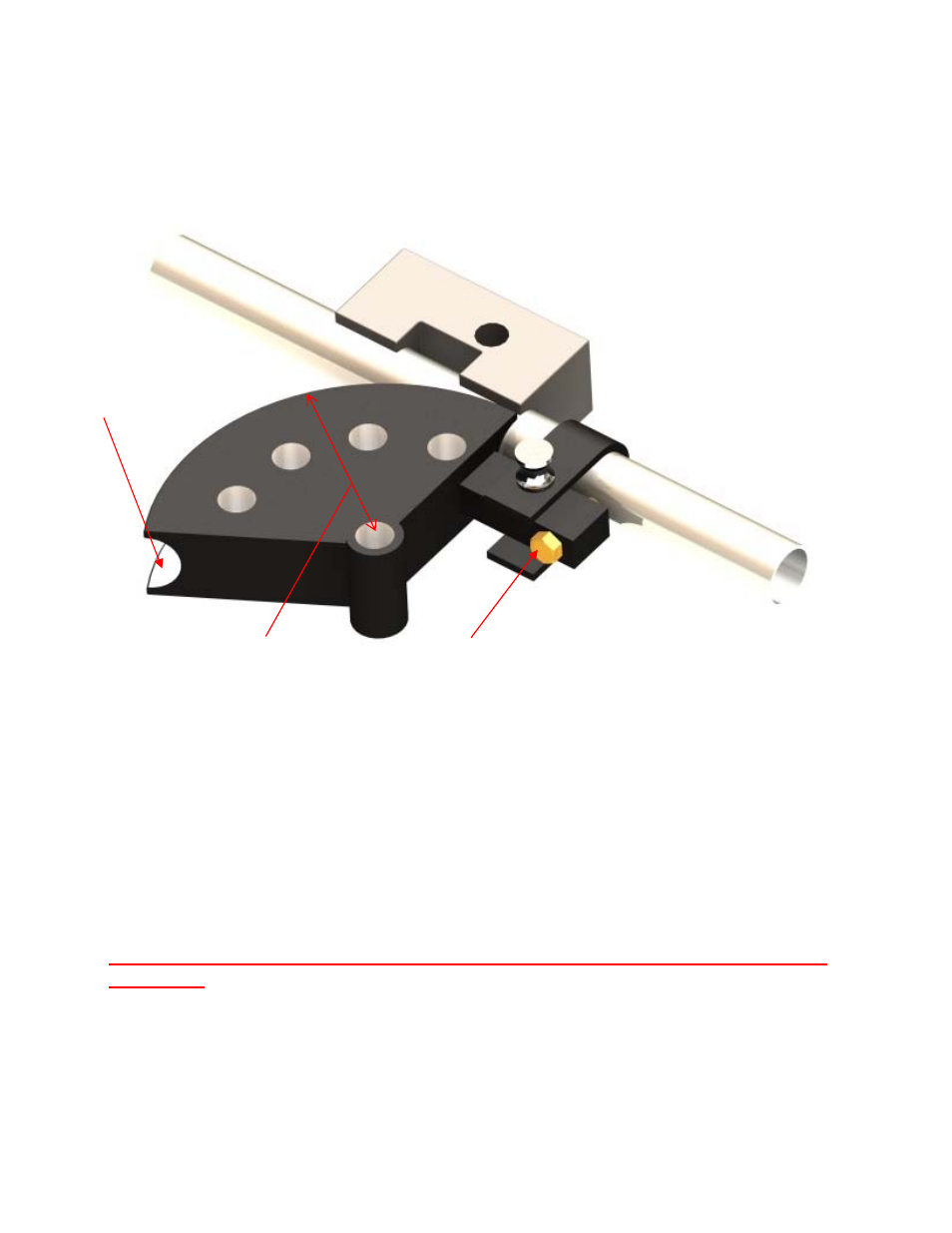

TO MEASURE RADIUS:

START AT IMAGINARY CENTER

OF SLEEVE, MEASURE TO EDGE

OF DIE.

TIGHTEN BOLT SO TUBE WILL NOT SLIP

ABSOLUTELY NO

GREASE IN RADIUS! THE

DIE RADIUS MUST BE

CLEAN & GREASE FREE

AT ALL TIMES!

NOTE: ALL ROUND TUBE RADIUS

MEASUREMENTS ARE “CENTER LINE RADIUS”

NOTE:

TO CALCULATE LENGTH OF TUBING USED IN A BEND,

MULTIPLY RADIUS OF BEND X 6.28 X DEGREE OF BEND,

THEN DIVIDE BY 360

EXAMPLE:

6 INCH RADIUS, 90 deg. BEND WOULD BE:

6 x 6.28 x 90 / 360= 9.42

IMPORTANT!

LUBRICATING ALL PINS AND “METAL TO METAL” SURFACES WITH ALL PURPOSE

BEARING GREASE WILL GREATLY REDUCE THE EFFORT NECESSARY TO OPERATE THE BENDER

AND AT THE SAME TIME WILL GREATLY INCREASE THE OVERALL LIFE OF THE BENDER.

REMEMBER,

GREASE IS OKAY EVERYWHERE EXCEPT IN THE RADIUS OF THE MAIN DIE.

THE MAIN DIE MUST REMAIN DRY AT ALL TIMES OR THE TUBING COULD SLIP

AND KINK.

PLEASE NOTE:

WE HAVE VERY SIMPLE COMPUTER PROGRAMS AVAILABLE THAT WILL LAY OUT

YOUR JOB FOR YOU, IF YOUR BENDING REQUIREMENTS BECOME TOO COMPLEX.

WE APPRECIATE YOUR PURCHASING A PRO BENDER AND WE BELIEVE IF YOU FOLLOW

THE DIRECTIONS, WITH A LITTLE PRACTICE, YOU’LL BE PRODUCING PROFESSIONAL

ACCURATE BENDS EASILY.