Vent termination below grade – Vermont Casting 4065 User Manual

Page 17

17

Pinnacle & Stardance Direct Vent - Rear Vent Gas Heaters

20007066

X

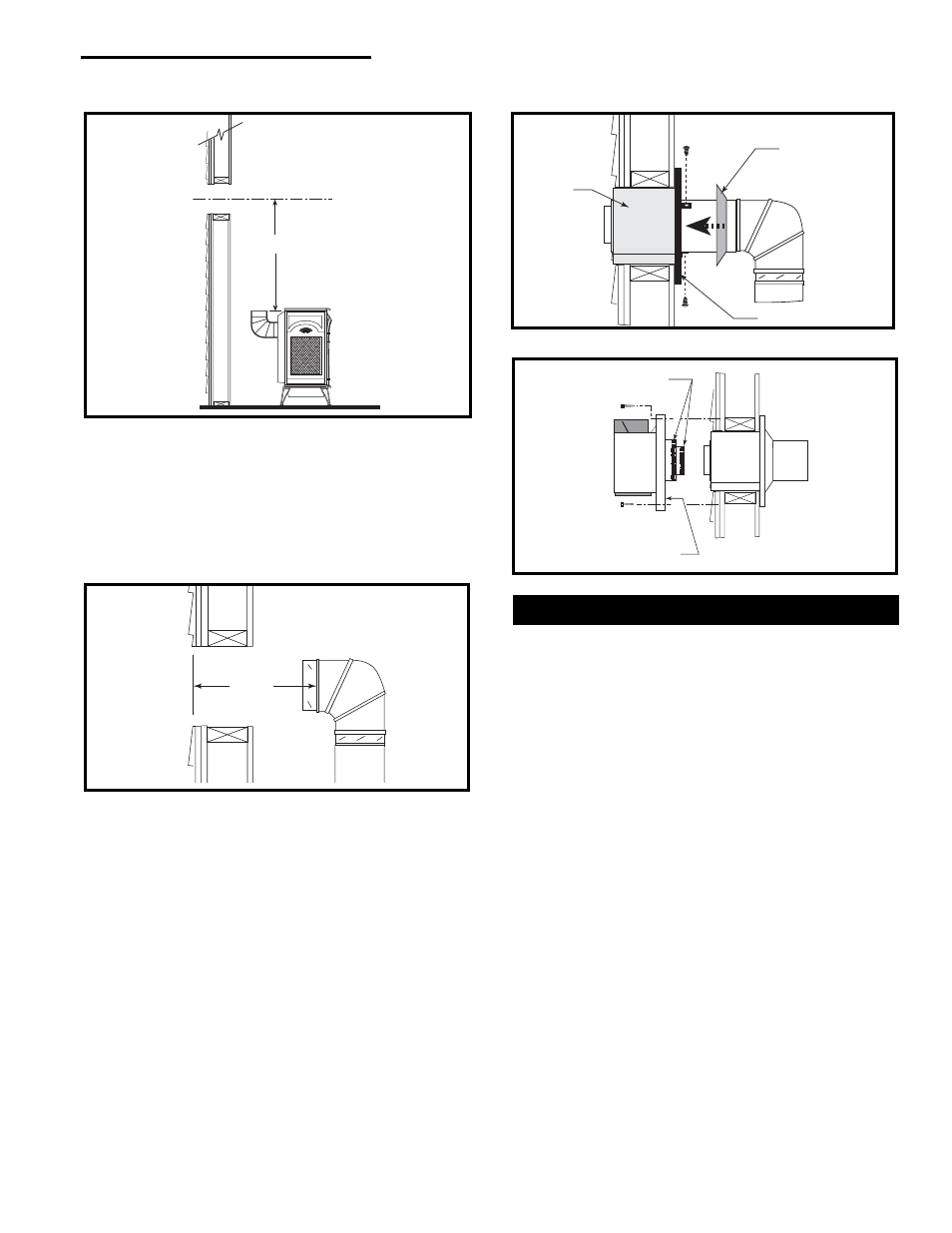

Fig. 26 Determine the vertical pipe length.

ST478

Trim Collar

Wall

Sleeve

Wall Plate

ST216

Fig. 28 Install the horizontal pipe and wall plate parts.

X

ST215

Fig. 27 Measure the horizontal length.

the elbow to the outside wall face, about 2” or the

distance required if installing a second 90

°

elbow.

(Fig. 27)

8. Slip the wall plate and trim collar over the interior

end of the horizontal pipe and install into the wall

sleeve. Seal the joint inside the wall plate if needed

to keep cold air from being drawn into the home.

9. Connect the horizontal pipe to the elbow. Fasten the

wall plate to the pipe with three sheet metal screws.

Slide the trim collar up against the wall plate to cover

the screws. (Fig. 28)

10.Install the vent terminal. (Fig. 29) Guide the inner

and outer vent termination collars into the adjacent

pipes. Double check that the vent pipes overlap the

collars by 2”. Fasten the termination to the wall with

the screws provided, and caulk the joint with weath-

erproof sealant.

11.Install Charcoal Gray Pipe Rings (#7FSDRG) or

Polished Brass Pipe Rings (#7FSDRP) at pipe

joints, if desired.

Seal Both

Terminal Ends

Caulk Plate Joint with

Weatherproof Sealant

ST217

Fig. 29 Install the vent terminal.

Vent Termination Below Grade

Install Snorkel #7TDVSNORK when it is not possible to

meet the required vent termination clearances of 12”

(305mm) above grade level. The snorkel kit will allow

installation depth of down to 7” (178mm) below grade

level. The seven inches is measured from the center of

the horizontal vent pipe as it penetrates the wall. If the

venting system is installed below grade, a window

well must be installed with adequate and proper

drainage. (Fig. 30)

NOTE: Be sure to maintain side wall clearances and

vent run restrictions. Refer to Figures 3 through 9.

1. Establish the vent hole through the wall.

2. Remove soil to a depth of approximately 16”

(400mm) below the base of the snorkel. Install a

window well (not supplied). Refill the hole with 12”

(305mm) of coarse gravel and maintain a clearance

of at least 4” (102mm) below the snorkel. (Fig. 30)

3. Install the vent system as described on Pages 14-

17.

4. Be sure to make a watertight joint around the vent

pipe joint at the inside and outside wall joints.

5. Apply high temperature sealant around the inner and

outer snorkel collars. Join the pipes and fasten the

snorkel termination to the wall with the screws

provided.