Campbell Hausfeld CHN10500 User Manual

Page 5

5

CHN10500

oPEraTiNG iNsTrUCTioNs

(Continued)

is greater . Use 1/4 inch air hose for

runs up to 50 feet . Use 3/8 inch air

hoses for 50 foot run or longer .

4 . Use a pressure regulator on the

compressor, with an operating

pressure of 0 psi - 125 psi . A pressure

regulator is required to control

the operating pressure of the tool

between 60 psi and 100 psi .

oPEraTioNal MoDE

Always know the

operational mode of

the tool before using. Failure to know

the operational mode could result in

death or serious personal injury.

TriGGEr oNlY MoDE (WiTH

TriGGEr loCK)

The tool is a single-actuator device . This

mode requires that, with the trigger

lock not positioned in the safe mode,

only a pull of the trigger will fire a

fastener .

After verifying there are no fasteners

in the tool, safety check the operation

of the activated trigger lock to prevent

the tool from firing a fastener before

storage . Always disconnect from

compressed air when not in use .

loaDiNG/UNloaDiNG THE Tool

1 . Always disconnect the tool from

the air supply before loading

fasteners .

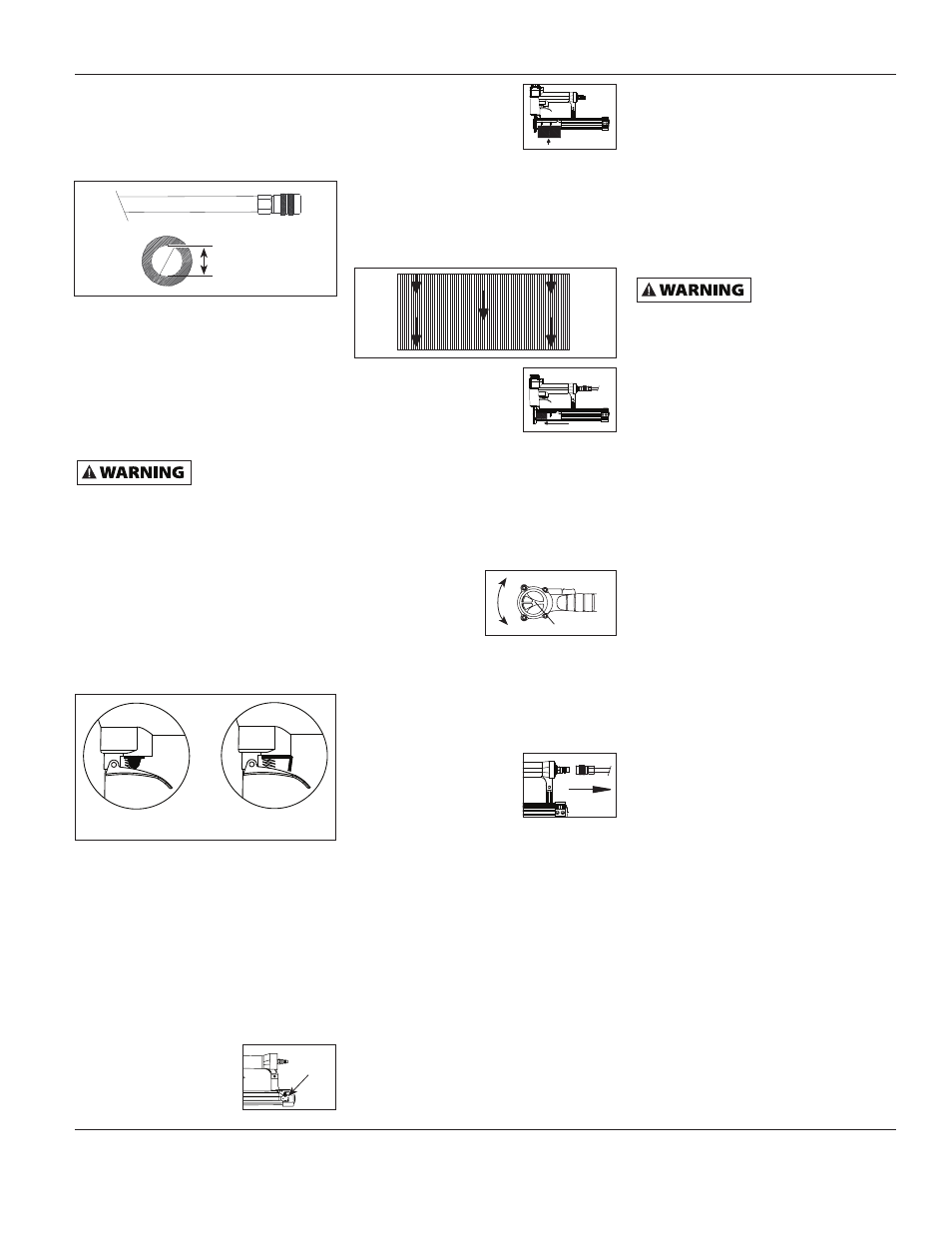

2 . Push the latch button .

Pull back on the

magazine cover fully .

3 . Insert a stick of

fasteners into the

magazine under the

automatic nail length

plate . Make sure

pointed ends of pins are resting on

bottom ledge of magazine when

loading . Make sure pins are not dirty

or damaged . Pins are marked for

direction of loading .

4 . Push the magazine

cover forward until

latch engages .

5 . Always unload all fasteners before

removing tool from service .

Unloading is the reverse of loading,

except always disconnect the air

supply before unloading .

aDJUsTiNG THE DirECTioN of THE

EXHaUsT

The tool is

equipped with an

adjustable direction

exhaust deflector . This is intended to

allow the user to change the direction

of the exhaust . Simply twist the

deflector to any direction desired .

ClEariNG a JaM froM THE Tool

1 . Disconnect the air

supply from the tool .

2 . Remove all nails from the magazine

(see "Loading/ Unloading The

Nailer") . Failure to do so will cause

the nails to eject from the front of

the nailer .

3 . Completely remove the two (2) small

nose screws and the top nose plate

to reveal the jammed fastener .

4 . Using caution not to bend or

damage the driver blade, use a pick

or some other pointed object to pry

free and clear the jammed fastener .

UsEr-MaiNTENaNCE

iNsTrUCTioNs

TECHNiCal sErviCE

Please call our Tool Hotline at 1-800-

543-6400 with any questions regarding

the operation or repair of this tool or

for additional copies of this manual .

fasTENEr aND rEPlaCEMENT

ParTs

Use only 23 gauge

headless micropins

(or equivalent - see Fastener

Interchange Information). Tool

performance, safety and durability

could be reduced if improper fasteners

are used. When ordering replacement

parts or fasteners, specify by part

number.

Tool rEPair

Only qualified personnel should repair

the tool and they should use genuine

Campbell Hausfeld replacement parts

and accessories, or parts and accessories

which perform equivalently .

DrivEr blaDE CarE aND

rEPlaCEMENT

In order to properly drive the

tiny micropins and leave a nearly

undetectable hole, the tips of the driver

blades end in a fine point and are

therefore quite vulnerable to abuse and

extended use .

To maximize the life of the blade,

closely examine fasteners for defects .

Do not use defective or improper

fasteners . Also load fasteners in the

proper orientation; the pin points and

the arrows always point toward the

wood surface . Drive fasteners into wood

products only (see "Loading/ Unloading

The Nailer") .

Even with good care, extended use

of the tool may eventually lead to tip

failure . Replacement driver assemblies

can be purchased by calling 1-800-

543-6400 and refer to part number

SKN12600AV .

latch

button

150 psi or greater

3/8 inch I .D .

rotate

Lock

Unlock

www.chpower.com