FASS FA D08 220G User Manual

Page 8

C.

Connect the WH-1005 wire harness branch coming from the relay to the factory power source re-

moved in the Step 1b.

B.

Disconnect power source to the factory lift pump.

D.

Secure Relay in an upright position, as shown, to prevent moisture from entering. Di-electric grease

may be applied to prevent corrosion. Examples of locations to secure relay:

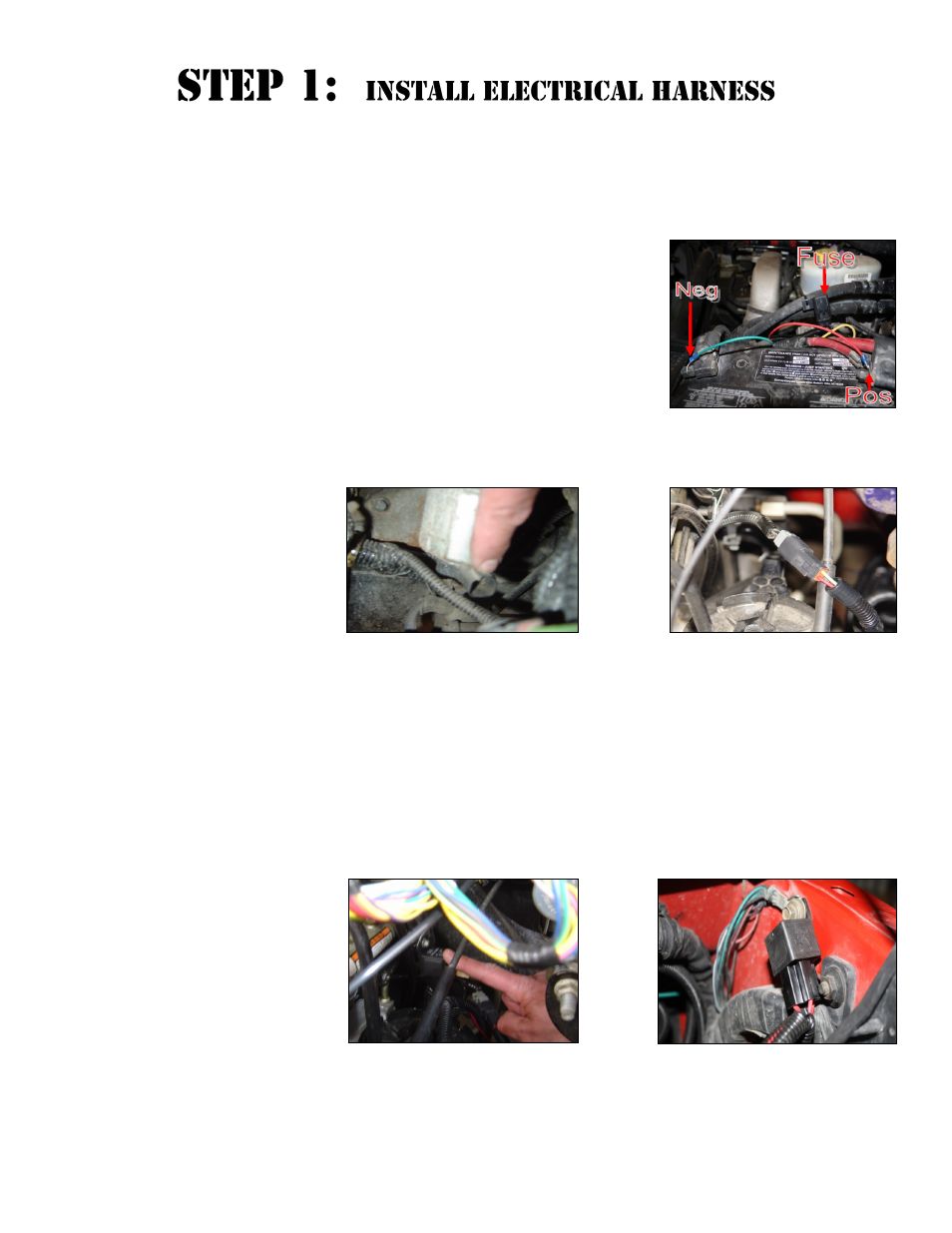

A.

Using ring terminals, attach red wire of the WH-1005 to the positive

battery terminal. Attach green wire to a clean ground, preferably the

negative battery terminal. Secure fuse block in a location protected from

outside elements. Use of corrosion preventative spray is recommend-

ed.

E.

Route the WH-1005 wire harness along the frame rail to the mounting location of the FASS fuel

pump.

The installation of the electrical harness is done first, allowing power to be applied to the pump for

lubrication purposes later in the installation.

2003-2004

1998.5-2002

- T D07 095G (20 pages)

- T D07 220G (20 pages)

- T D08 095G (19 pages)

- T D08 220G (21 pages)

- T D09 095G (19 pages)

- T D10 125G (20 pages)

- T D02 095G (19 pages)

- T F17 125G (21 pages)

- T F17 200G (21 pages)

- T F17 220G (21 pages)

- T F16 095G (19 pages)

- T F16 220G (20 pages)

- T F16 260G (20 pages)

- T F14 125G (21 pages)

- T F14 200G (21 pages)

- T F14 220G (21 pages)

- T C11 095G (20 pages)

- T C10 095G (20 pages)

- T C10 220G (21 pages)

- T 095G (23 pages)

- T 220G (23 pages)

- T 260G (23 pages)

- T UIM 150G (23 pages)

- T UIM 220G (23 pages)

- T UIM 260G (23 pages)

- T 080G (23 pages)

- T 125G (23 pages)

- T 200G (23 pages)

- FA D05 095G (16 pages)

- FA D05 220G (16 pages)

- FA D05 260G (16 pages)

- FA D07 095G (16 pages)

- FA D07 220G (16 pages)

- FA D07 260G (16 pages)

- FA D08 095G (16 pages)

- FA D08 260G (18 pages)

- FA D09 095G (15 pages)

- FA D10 125G (18 pages)

- FA D10 220G (19 pages)

- FA D10 240G (19 pages)

- FA D02 095G (15 pages)

- FA F17 125G (19 pages)

- FA F17 200G (19 pages)

- FA F17 220G (19 pages)