Step 1 – FASS T F16 220G User Manual

Page 8

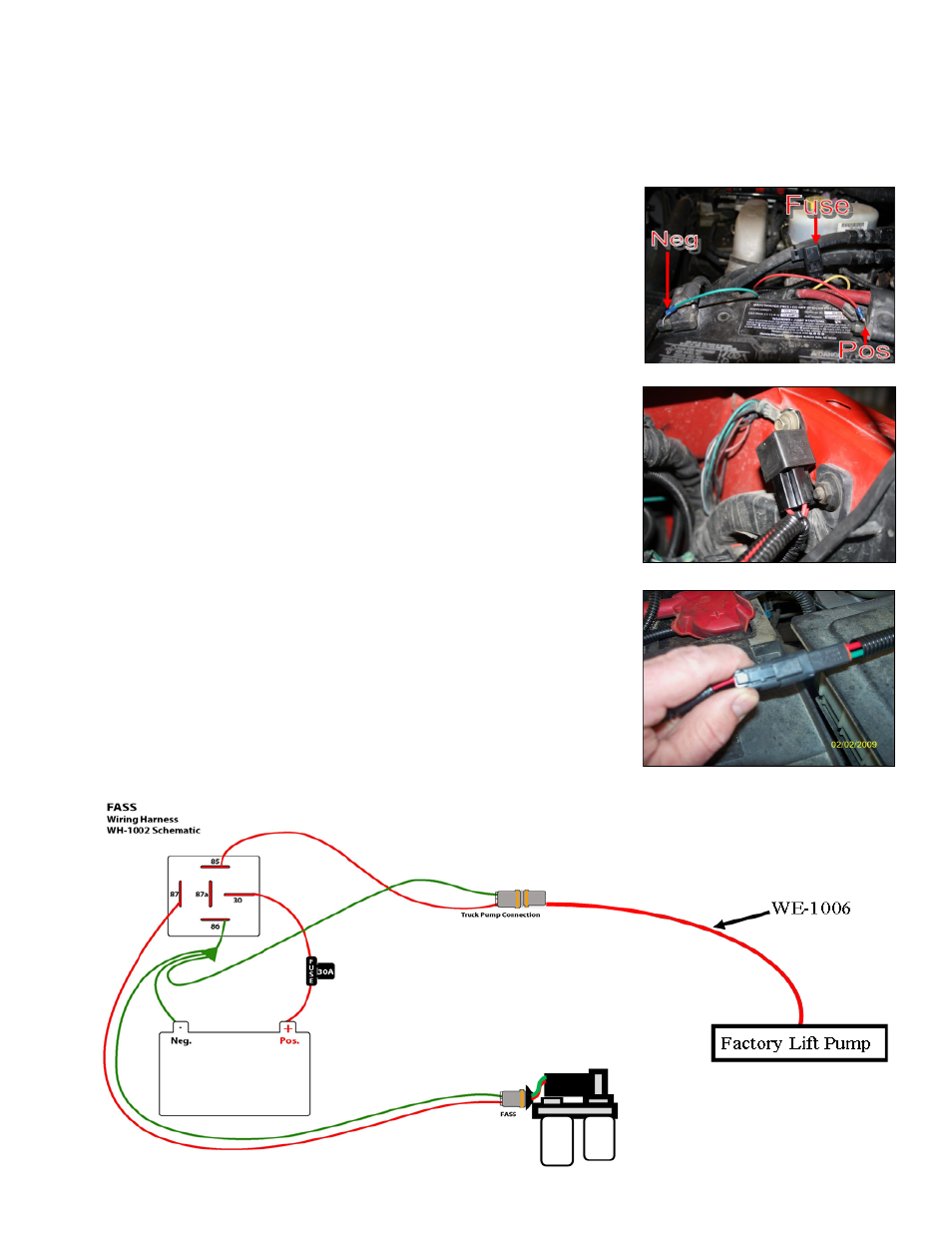

B.

Secure Relay in an upright position, as shown, to prevent moisture

from entering. Di-electric grease may be applied to prevent corrosion.

A.

Using ring terminals, attach red wire of the WH-1002 to the positive

battery terminal. Attach green wire to a clean ground, preferably the

negative battery terminal. Secure fuse block in a location protected

from outside elements. The use of a corrosion preventative on electri-

cal connections is recommended.

C.

Connect WE-1006 to the female lead of the WH-1002 coming off

the relay. Route the WH-1002 and WE-1006 along frame rail to the

factory lift pump. Completion of this step will be addressed in the

mounting step.

Step 1:

Install Electrical Harness

The installation of the electrical harness is done first, allowing power to be applied to the pump for

lubrication purposes later in the installation.

- T D07 095G (20 pages)

- T D07 220G (20 pages)

- T D08 095G (19 pages)

- T D08 220G (21 pages)

- T D09 095G (19 pages)

- T D10 125G (20 pages)

- T D02 095G (19 pages)

- T F17 125G (21 pages)

- T F17 200G (21 pages)

- T F17 220G (21 pages)

- T F16 095G (19 pages)

- T F16 260G (20 pages)

- T F14 125G (21 pages)

- T F14 200G (21 pages)

- T F14 220G (21 pages)

- T C11 095G (20 pages)

- T C10 095G (20 pages)

- T C10 220G (21 pages)

- T 095G (23 pages)

- T 220G (23 pages)

- T 260G (23 pages)

- T UIM 150G (23 pages)

- T UIM 220G (23 pages)

- T UIM 260G (23 pages)

- T 080G (23 pages)

- T 125G (23 pages)

- T 200G (23 pages)

- FA D05 095G (16 pages)

- FA D05 220G (16 pages)

- FA D05 260G (16 pages)

- FA D07 095G (16 pages)

- FA D07 220G (16 pages)

- FA D07 260G (16 pages)

- FA D08 095G (16 pages)

- FA D08 220G (18 pages)

- FA D08 260G (18 pages)

- FA D09 095G (15 pages)

- FA D10 125G (18 pages)

- FA D10 220G (19 pages)

- FA D10 240G (19 pages)

- FA D02 095G (15 pages)

- FA F17 125G (19 pages)

- FA F17 200G (19 pages)

- FA F17 220G (19 pages)