Dynalco DYNA-GEN Flywheel Generator System User Manual

Page 4

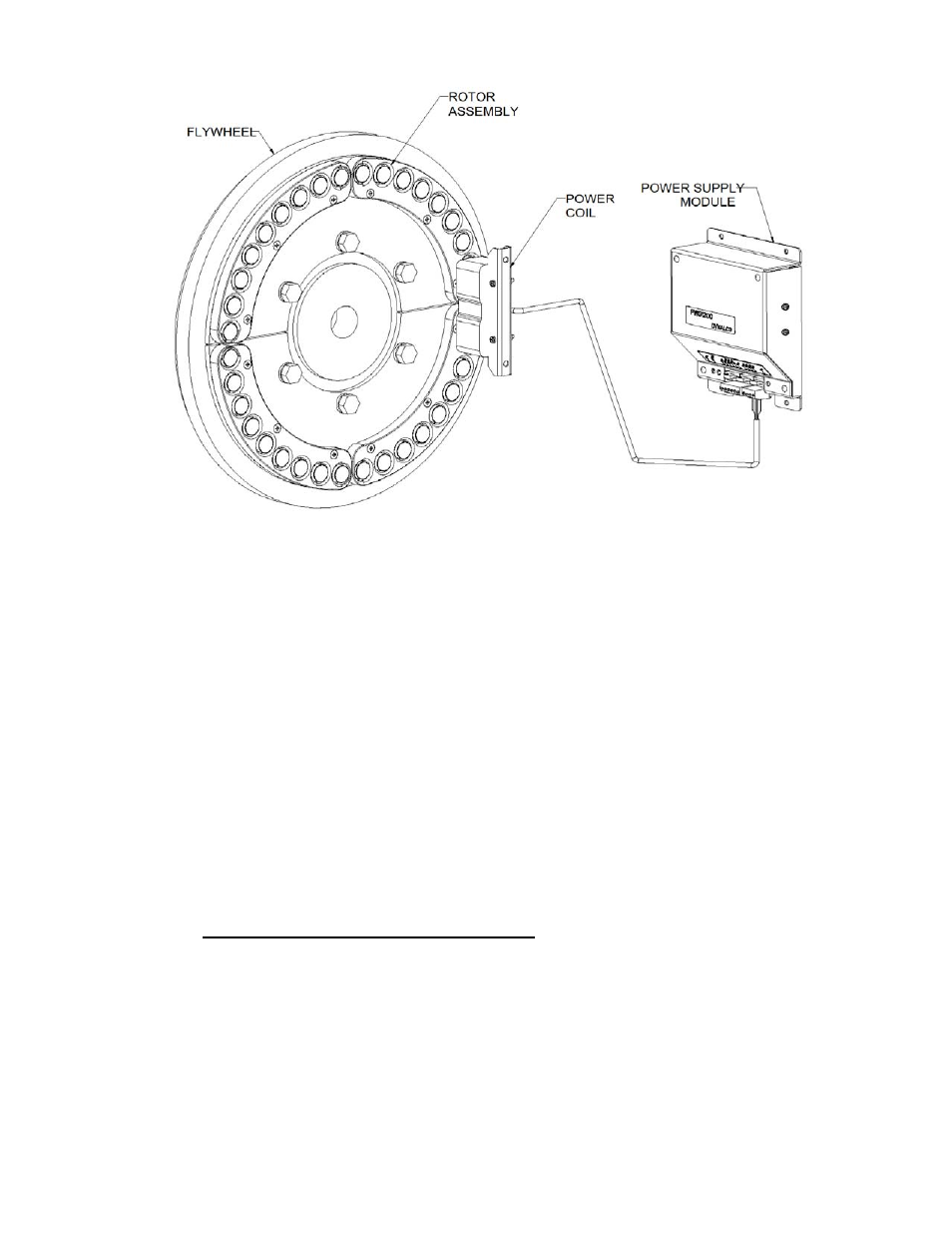

FWG-1200 System

Installation:

The FWG-1200 system is designed to fit almost any standard industrial engine given the proper

space for all components. The three subassemblies shown above can be mounted to existing

engine components or modified to meet user requirements. The following instructions describe the

mounting procedures for each of the three subassemblies.

Rotor Assembly: The Rotor Assembly consists of (2) halves that are to be mounted to the engine

flywheel. The face plate halves of the rotor assembly are constructed of ¼” steel and need to be

drilled to allow for custom mounting using a minimum of (3) hex bolts on each half. Permanent red

Loctite should be used to secure the mounting bolts.

Power Coil: The power coil must be mounted on a bracket so that the core laminations of the

transformer face the outer circumference of the generator assembly, in line with the magnets. The

bracket must be sturdy enough to limit vibration and gap movement with the strong pull of the

magnets. The gap must be set to 0.070 +/- 0.010 inches. A gap of less than 0.070” will cause

excessive voltage into the Power Supply Module and could damage components. Once the air

gap has been established, the Power Coil can be attached to the bracket. The bracket can be

attached to the engine or supporting frame depending on space availability and user needs.

Power Supply Module: The Power Supply Module should be mounted where it will be protected

from weather, preferably within an existing panel or a suitable enclosure. It is also advisable to

keep away from heat sources such as the exhaust manifold. Shock mounts should be used if the

vibration is high where the Power Supply Module is going to be used.

4