Drucker Diagnostics Model 642VES Centrifuge User Manual

Page 11

Safety:

Horizon Lid Safety Switch:

The Horizon lid is secured to the top of the cabinet by a latching knob

and pawl system. When the knob is rotated clockwise, the pawl grips the underside of the cabinet

opening and prevents the lid from opening. A mechanical stop positions the pawl and prevents it from

rotating completely. When rotated to the stop position, the pawl makes contact with a micro–switch

mounted underneath the cabinet top.The lid safety switch prevents the centrifuge from operating

while the lid is open. The yellow ‘LATCHED’ indicator light on the front of the machine will illuminate

when the lid has been latched properly.

Horizon Lid Safety Interlock System:

In addition to the Lid Safety Switch, the Horizon has a true

“0 RPM” lid locking system. The lid safety interlock system keeps the lid locked at all times, (even

during power failure), and requires that the rotor be at rest in order to unlock the lid. The centrifuge

will not allow entry into the rotor chamber unless the centrifuge has power and the rotor is stopped.

To open the lid, make sure that the centrifuge is plugged in and, with the rotor stopped, press the

‘OPEN / STOP’ button.

NOTE:

After the centrifuge has started spinning, it may be possible to rotate the lid knob enough to

cause the pawl to lose contact with the lid safety switch. If this happens, the centrifuge motor may lose

power, but the lid will still remain locked. If the knob is accidentally moved and this situation should

occur, rotate the knob fully clockwise to its stop position and the centrifuge will resume operation.

Circuit Breaker:

The Horizon is protected with a 4 Amp circuit breaker located at the rear of the machine mounted

to the base. Any electrical short circuit will cause the breaker to cut power to the machine.

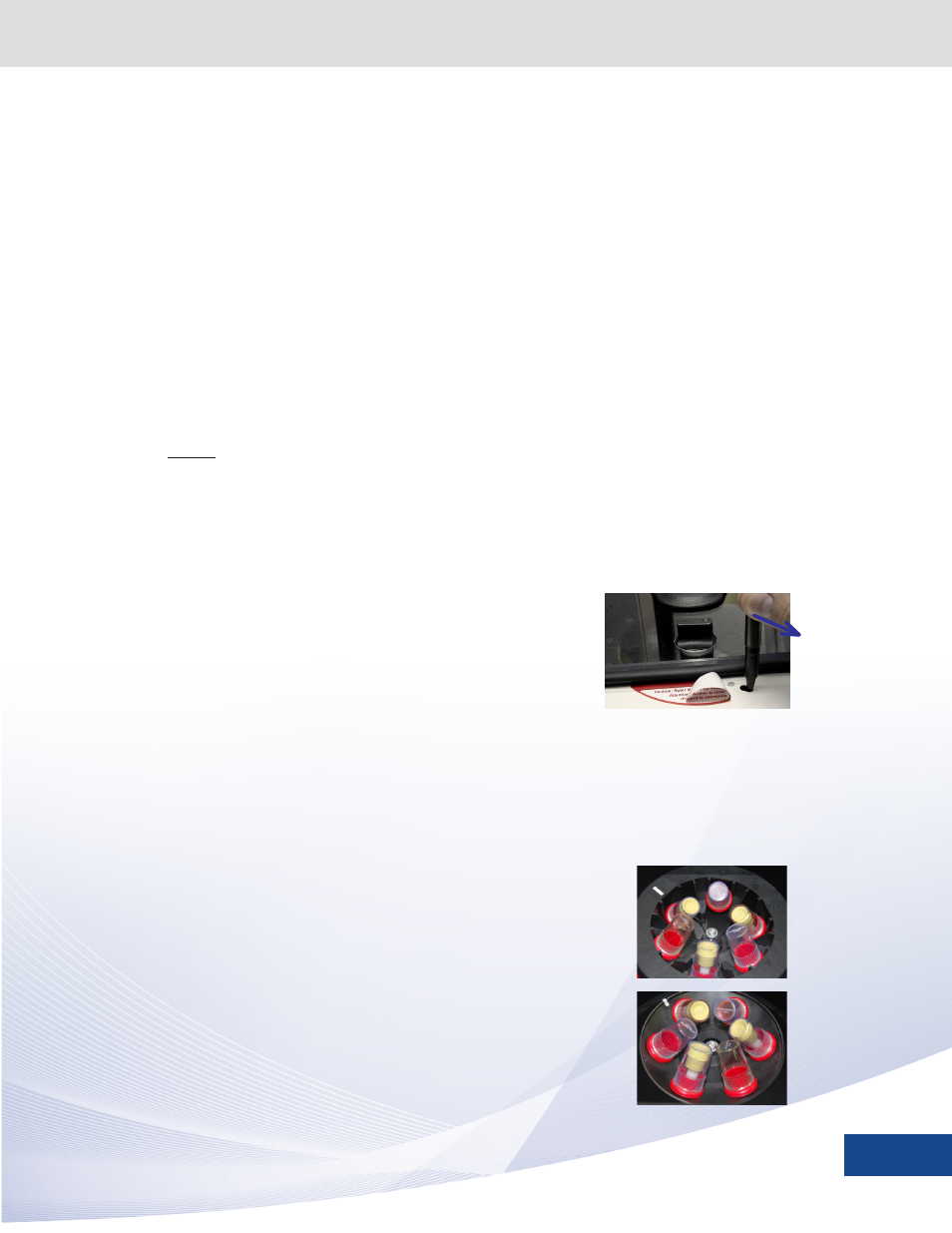

Emergency Rotor Chamber Entry:

In the event of power failure, it may be impossible to unlock the lid by

conventional means. In this case, entry into the rotor chamber may

be made by removing the latch label and using a pen to manually

disengage the locking mechanism (see photo). Pull the mechanism

towards the control panel and then unlatch and open the lid. If the unit

is damaged, contact your authorized dealer or The Drucker Company.

Calibration and Earth Ground Testing:

It is recommended that the top speed, ground continuity and line leakage be tested every two years for

continued safe operation. Contact The Drucker Company for further information or testing availability.

For PAT testing-ensure that your portable appliance tester is set to DC flash test. The centrifuge has

an EMC mains filter. This can result in spurious failures if an AC dielectric test is used. Apply the

minimum test cycles: repeated flash tests can lead to deterioration of insulation.

Speed Verification:

1. Press the STOP/OPEN button to unlock and open the lid.

2. Place the counter balance tubes (p/n 7700002, available from The

Drucker Company) into the tube carriers/holders in the odd numbered

locations on the rotor, leaving the other three tube carriers/holders

empty as shown in the pictures on the right.

3. Make sure there is a reflective strip on the rotor.

4. Close and lock the lid.

5. Press the MENU key and choose the desired parameters to be tested

by either choosing a memory location or selecting parameters with

the scroll keys. Make sure the correct tube size is selected.

6. Press MENU to exit the program menu.

7. Press the START button to begin the run.

8. Using a non-contact tachometer measure the rpm by aiming it where

the reflective strip is located.

9. Verify that the speed is within ±100 rpm of the set speed.

The Horizon Model 642VES complies with all requirements of UL 61010A-1, UL 61010A-2-020,

UL 61010A-2-010, UL 3101-2-20, Can/CSA C22.2 No. 1010.1, Can/CSA C22.2 No.1010.2.020

11