Operating instructions, 1 field of application, 2 scope of delivery – Cooper Instruments & Systems LXT 971 Rotating Torque Load Cell User Manual

Page 4: 3 installation and removal, 4 interface description, 5 operation

CF 59

4

Rev. I September 2013

7. Operating Instructions

7.1 Field of Application

The torque sensor is intended for use in an industrial environment (e. g. test

bench).

7.2 Scope of Delivery

The torque sensor set consists of the sensor itself (signal pick-up and signal

processing integrated into sensor housing), one connecting cable with a soldered plug, key stones and the

instruction manual.

7.3 Installation and Removal

Make sure to install the sensor shafts exactly with the proper aligned

connecting shafts. The key stone adapter / square endings of the connecting shafts are to be attached forceless

to the corresponding ones of the sensor. No external axial force should be on the housing of the sensor by fixing

it. The spanner flat is for the protection of the sensor from distortion. A maximum cable length of 5m must not be

exceeded. Using a cable or connector other than supplied with the unit, or a similar cable that is of a different

length may affect the overall performance of the sensor. DO NOT REMOVE THE SHAFT WITH TORQUE

APPLIED TO THE SENSOR.

7.4 Interface Description

Mechanical connection: The key stone adapters on both ends of the measurement shaft are intended for torque

transmission.

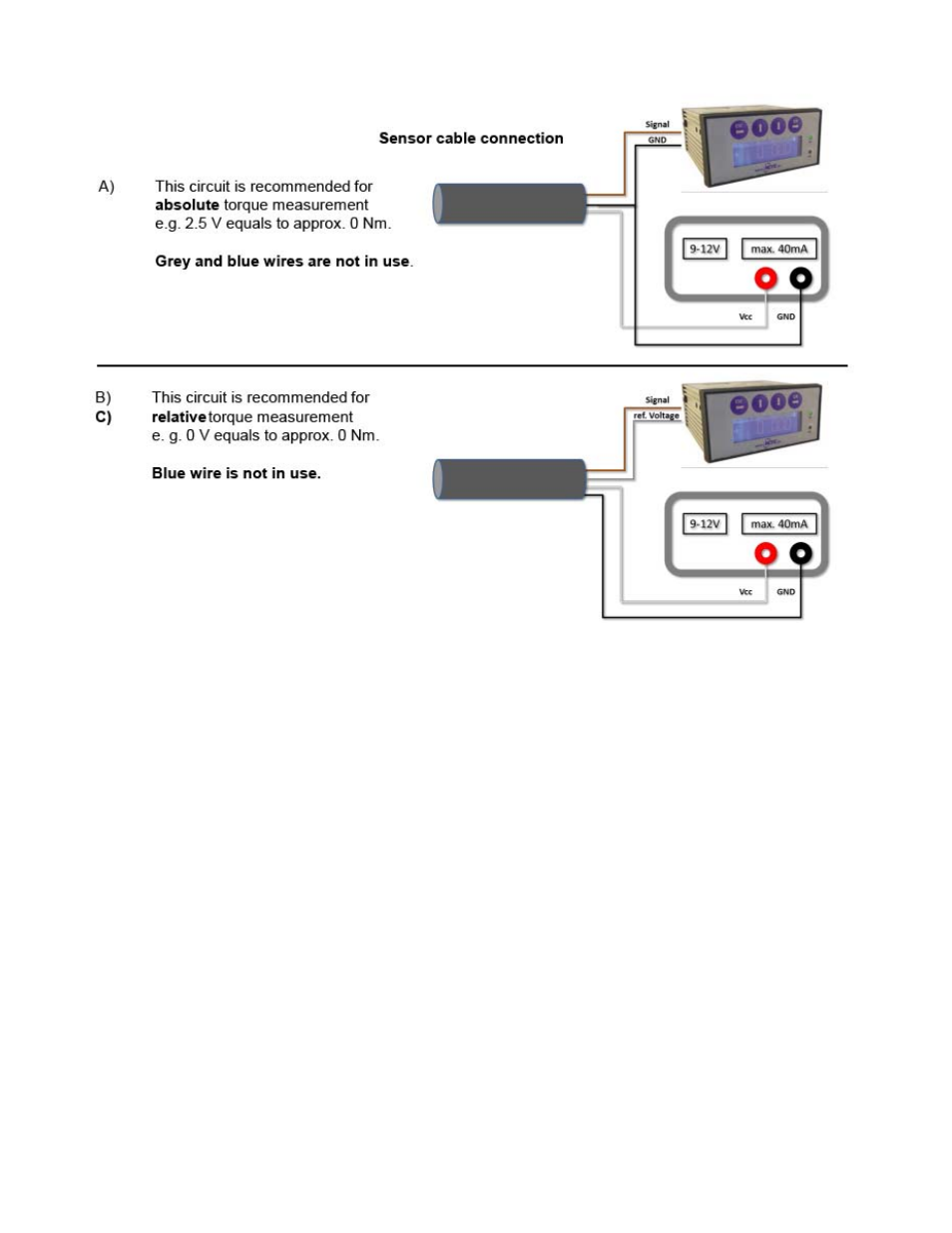

Electrical connector: On the sensor housing there is a 5-pin socket for the power supply and the signal output

(see Chapter 6 Connection Plan).

7.5 Operation

(in regular case or in optimal case) Optimal measurement parameters can be achieved

when the sensor is applied in accordance to the specification. Use the sensor only for short periods of time at