0 connection plan, The output v – Cooper Instruments & Systems LXT 971 Rotating Torque Load Cell User Manual

Page 3

CF 59

3

Rev. I September 2013

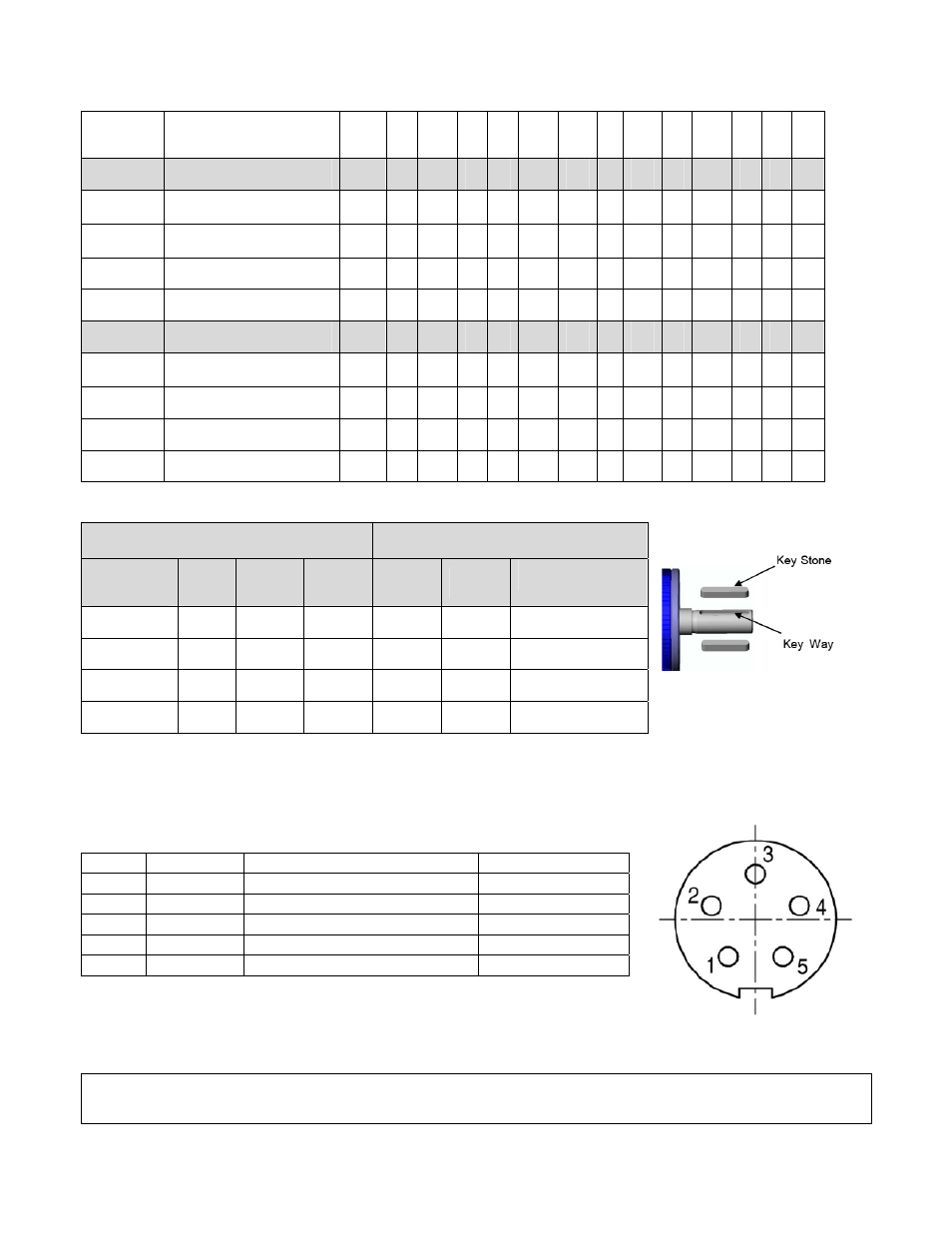

Dimensions

Nominal Torque Capacity

[Nm]

A B

C

D

E

F

G

H

K

L M N P

S

LXT 970

¼ inch

2.5 - 5.0 - 7.5 - 17.5

95.5

70

9.5

-

40

16

8

5

12

- 43.9 15 37

1.5

3/8 inch

75

107 70

13

-

50

24

8

5

18

- 43.9 18 47

1.5

½

inch

175-250

123.5 70

18.5

-

50

35

8

5

24

- 43.9 18 47

1.5

¾

inch

500

146 87

29.6

-

60

29.6

10.5

2

33.5

- 61.4 19 57

1.5

LXT 971

Ø 9 mm

2.5 - 5.0 - 7.5 - 17.5

125 70

27.5

9

40

-

8

5

-

23 43.9 15 37

1.5

Ø

14

mm

75

139 70

34.5

14

50

-

8

5

-

30 43.9 18 47

1.5

Ø

19

mm

175-250

179 70

54.5

19

50

-

8

5

-

50 43.9 18 47

1.5

Ø 25 mm

500

220

87

66.6

25

60

-

10.5

2

-

-

61.4

19

57

1.5

The second Key Way (only for LXT

971 500) in mirrored position (180°)

5.0 Connection Plan

Pin Color

Description

Value

1

White

Supply Voltage V

cc

9V – 12V

2

Brown

Signal Output analog

3 Black

Ground

GND

4 Blue

Not

Used

5

Grey

Reference Voltage V

ref

2.5v

The output V

ref

is a constant 2.5 V and represents the virtual zero point for

direct +/‐ torque measurement (See below “Sensor cable connection” section B).

At the user side one plug with shielding termination (360°) should be used. If not possible the

shielding should accompany the signal as far as it could!

Dimensions Keyway [mm]

Keystones

Shaft

Diameter

Width

Depth

Length

Height

Length

Amount

Ø 9 mm

3

1.8

18.5

3

18

1

Ø 14 mm

5

3

25.5

5

25

1

Ø 19 mm

6

3.5

45.5

6

45

1

Ø 25 mm

8

4

50.5

8

50

2