Installation of alarm, Sensor, 250psi – Amico Valve Alarm Combo Unit User Manual

Page 10

CAUTION: The microprocessor circuitry on the alarm valve unit contains sophisticated integrated

semiconductors. If it becomes necessary to remove a module, PLEASE hold the boards by the edges.

DO NOT TOUCH any of the components on the board. Static discharge can cause the modules to

malfunction or become damaged.

Sensor

LOCAL (Inside the Back Box)

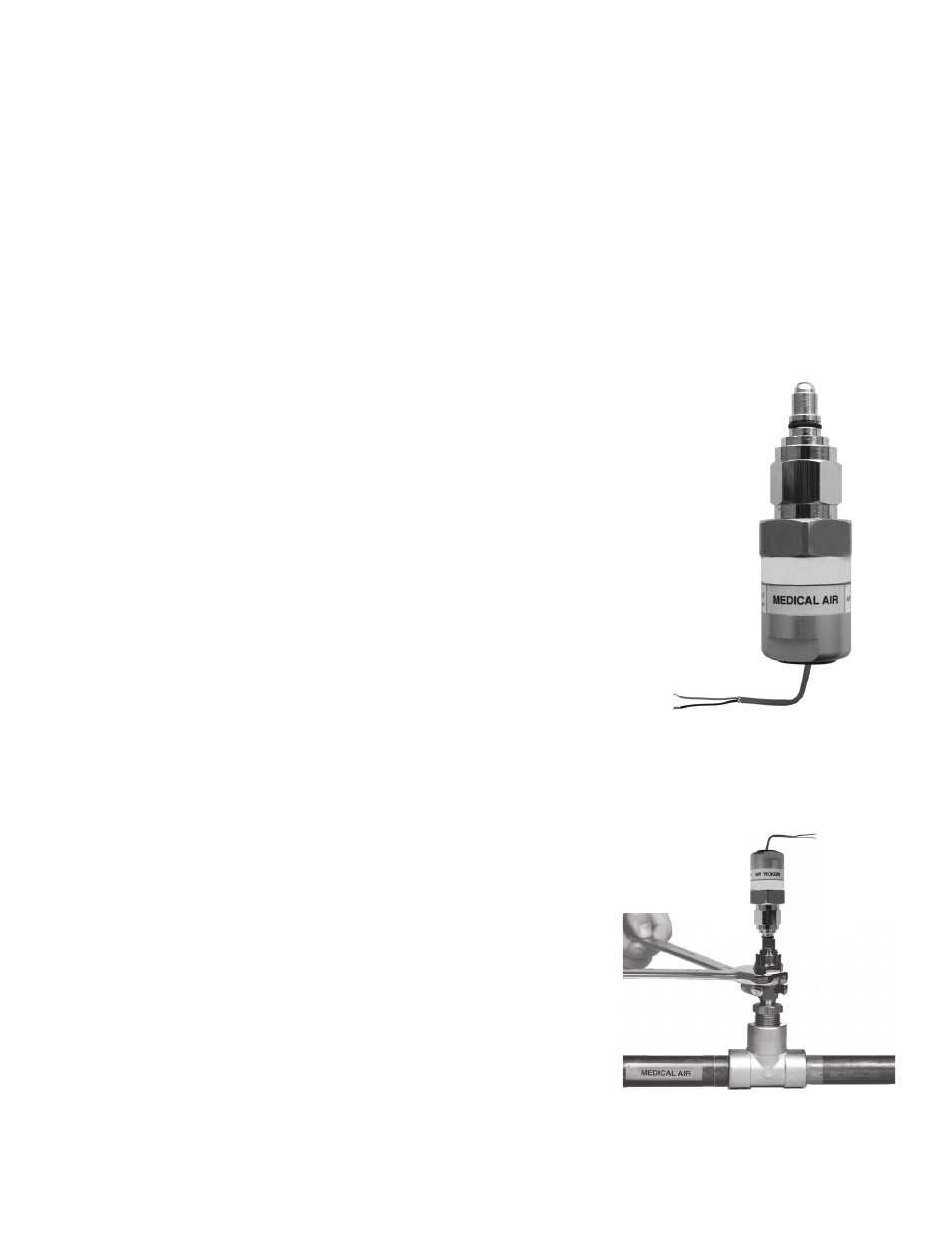

1. Locate the gas specific sensor module to be installed.

2. In the back box, there are colour coded gas labels located under

the DISS Demand check valves. Each label identifies where each

sensor module is to be placed.

3. The sensor module contains a gas specific DISS fitting. Push the

sensor module hex-nut and nipple adapter up into the demand

check-valve. With a wrench, tighten the nut so that it makes a

good seal.

NOTE: Pressure on sensors is not to exceed 250 psi for pressure

sensors and 30" for vacuum sensors

The sensor can reach pressure up to:

Mid Pressure 0-99 Psi

Hi Pressure 0-249 Psi

Vacuum 0-30" Hg

REMOTE (Outside the Back Box)

1. Connect a Tee (supplied by others) to the pipeline with a 1/4" NPT

female connection that will accept the DISS Demand check-valve.

2. Locate the gas specific sensor module to be installed.

3. Thread the DISS Demand check-valve into the correct gas

pipeline.

4. The sensor module contains a gas specific DISS fitting. Push the

sensor module hex-nut and nipple adapter up into the demand

check-valve. With a wrench, tighten the nut so that it makes a

good seal.

A m i c o M i c r o p r o c e s s o r B a s e d A l a r m

P a g e : 1 2

CAUTION: The microprocessor circuitry on the ALERT-2 alarm con-

tains sophisticated integrated semiconductors. If it becomes necessary

to remove a module, PLEASE hold the boards by the edges.

DO NOT

TOUCH any of the components on the board. Static discharge can

cause the modules to malfunction, or become damaged.

SENSOR

LOCAL (In the Back Box)

1.

Locate the gas specific

sensor module to be in-

stalled.

2.

In the back box, there are

colour coded gas labels

located under the DISS

Demand check valves. Each

label identifies where each

sensor module is to be

placed.

3.

The sensor module contains

a gas specific DISS fitting.

Push the sensor module

hex-nut and nipple adapter

up into the demand check-

valve. With a wrench, tighten the nut so that it makes a good seal.

NOTE: Pressure on sensors are not to exceed

250psi

for Pressure sensors and

30”

for Vacuum sensors

REMOTE (Outside the Back Box)

1.

Connect a Tee (supplied

by others) to the pipeline

with a 1/4" NPT female

connection that will accept

the DISS Demand check-

valve.

2.

Locate the gas specific

sensor module to be

installed.

3.

Thread the DISS Demand

check-valve into the

correct gas pipe line.

4.

The sensor module contains a gas specific DISS fitting. Push the

sensor module hex-nut and nipple adapter up into the demand

check-valve. With a wrench, tighten the nut so that it makes a

good seal.

Installation of Alarm

10

Amico Pipeline