Cannon CANTFS-03-NG User Manual

Page 13

12

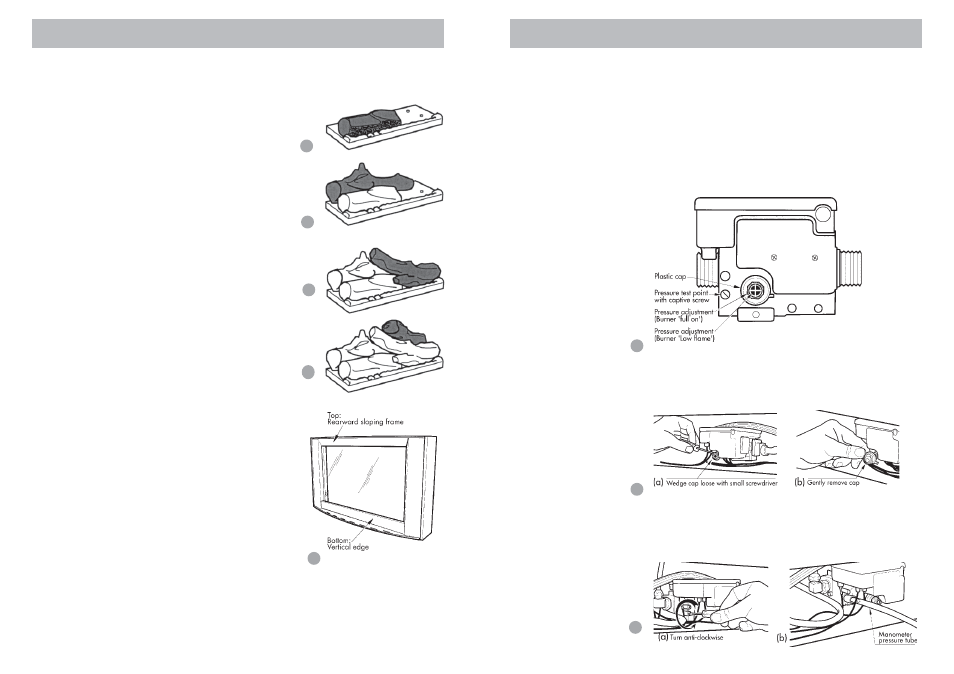

Position the four individually numbered logs in the following order on

the burner head as shown in figures 15 - 18. The male locating pins in

the burner head must engage with corresponding holes in the indi-

vidual logs.

a) Place log No.1 onto the 2 front left

pins on the burner head, ensuring that

the charring faces the front.

Refer figure 15.

b) Place log No.2 onto the 2 left

back pins. Refer figure 16.

c) Place log No.3 on single right

front pin, ensure fork locates over log

No. 2. Refer figure 17.

d) Place log No. 4 on single right

back pin, ensure left side of log rests

on depression in No. 3 log.

Refer figure 18.

13. Refit the inner glass, but do not

overtighten the screws.

14. Refit the front glass surround. En-

sure that the glass surround is re-

placed the correct side up. The

rearward sloping frame must be

at the top and the vertical edge

must be at the bottom. Refer figure

19.

Gas control

15. Gas control layout is as indicated in figure 20

Operate the heater on HIGH and LOW burner and all fan speeds.

The flame should be stable, no lifting from the burner, and the logs

should glow after approximately 15 minutes of operation on HIGH

burner.

15

18

19

17

16

Advise the user in the

operation of the heater.

13

If the flame is unstable:

❍ Check that the burner is located correctly.

❍ Check that the glass front is located correctly and is against the

sealing rope.

❍ Check that the gas pressure is correctly adjusted.

If the heater still does not operate to specification refer to the trouble-

shooting chart on pages 22 & 23, or contact Sampford IXL in your

state.

Pressures for ‘Burner full on’ and ‘Burner low flame’ are factory

set, however if pressures need to be checked or adjusted follow the

procedures described below and on the next two pages.

16. To check control outlet pressure at burner ‘Full on” and ‘Low Flame”

positions, remove the plastic cap from the regulator adjustment loca-

tion as indicated in figures 21 (a) & (b).

Gas pressure point

17. The pressure point is closed with a captive screw. Turn screw 6 revo-

lutions anticlockwise to open the pressure point as indicated on figure

22 (a) and place manometer tube over the test point as per figure 22

(b).

20

21

22