Quick setup guide for intelliag model cta – Great Plains CTA4000 Quick Start User Manual

Page 2

Quick Setup Guide for IntelliAg Model CTA

11001-1459C-201107

©2011 DICKEY-john Corporation

Specifi cations subject to change without notice.

STEP 5B: Material Confi guration Setup

(Granular Fertilizer Monitor)

16 different materials can be confi gured as seeding and fertilizer

controls. Material defaults on the Control Setup screen are Seed 1-4

(Granular Seed Control) Seed 5-8 (Granular Seed Monitor) Fert 1-4

(Granular Fertilizer Control) Fert 5-8 (Granular Fertilizer Monitor).

Reference the System Confi guration section in the Operator’s manual

for additional setup instructions.

Press the Control Setup button

.

At the Control Setup screen, select one of the 16 material but-

tons to edit (labeled Seed 1-8 and Fert 1-8).

Enter desired values from Table C.

Press the Control Setup button

to return to the Control

Setup screen.

Repeat steps 2-4 for additional materials.

Press the Channel Setup button

to enter channel setup

constants.

1.

2.

3.

4.

5.

6.

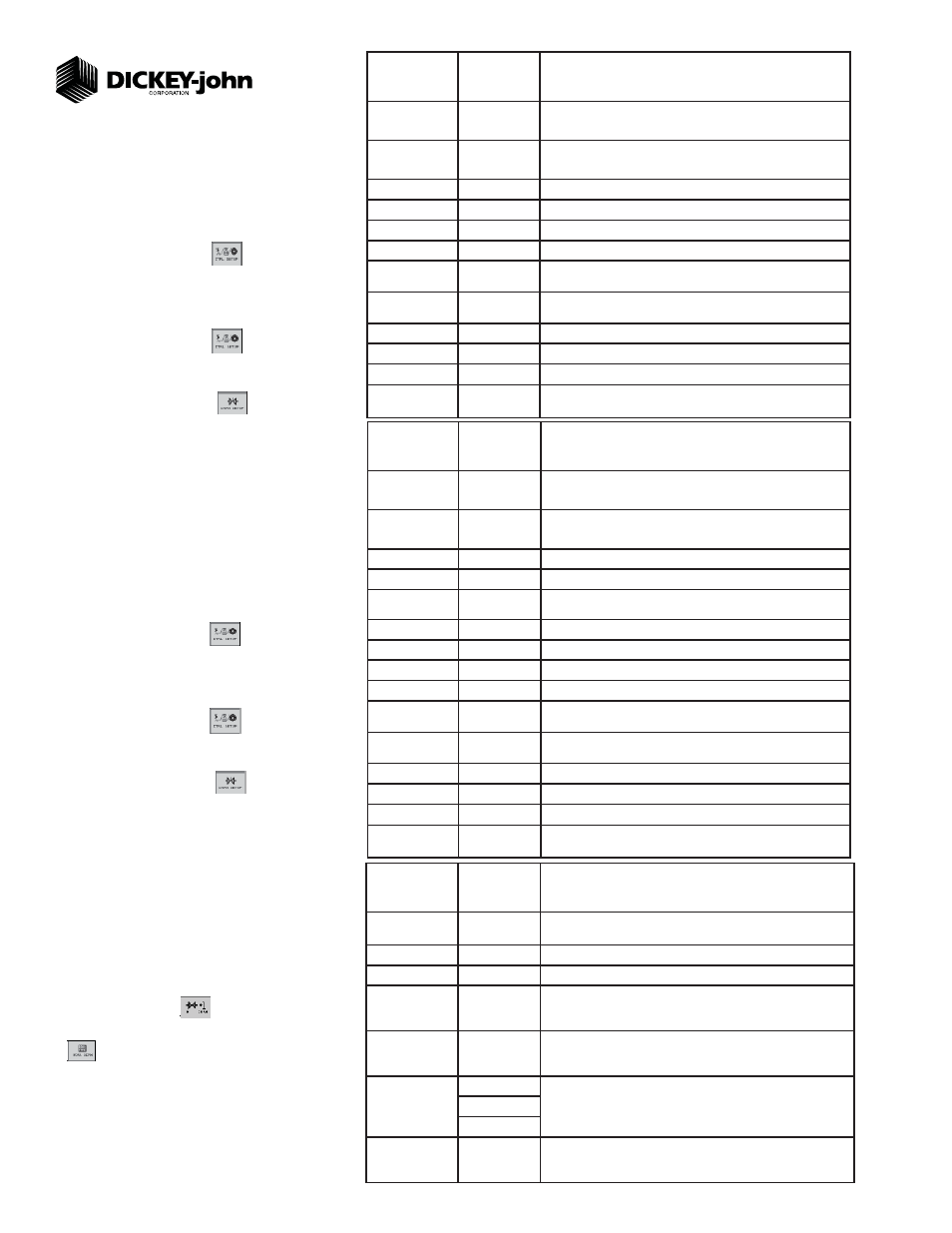

TABLE C:

Material Setup

Gran Fert Mon

Default Value/

Value to Enter Instructions/Defi nitions

Matrl Label

Fert 5

Material Name can be customized to accurately defi ne the material’s type.

Creating a name allows for quick identifi cation at the Material Summary

screen.

Type

Gran Fert

Monitor

Desired type of application control channel being used for a specifi c mate-

rial. The Material Type must correctly match the Control Type to be able to

select material from the Control Setup screen and operate properly.

Units

Lbs/Ac

Displays primary and secondary readout units in Lbs/ac or Kg/ha.

Target Rate

50 lbs/Ac

Desired rate of application in lbs/Ac.

Density

60 lbs/ft

3

Establishes the density of material in lbs/ft

3

.

# Towers

5

Establishes the number of towers for that channel.

Calibration

Constant

82500 Pul/ft

3

Number of pulses to drop 1 cubic foot/liter of material.

Variable Cal

Constant

Disabled

Adjusts the accuracy of the seed amount dispensed based on the seed

type. A selection of 25 pre-defi ned seed types are available.

Low RPM Limit

1

Set to desired min fert meter RPM.

High RPM Limit

50

Set to desired max fert meter RPM.

Prod Level Alarm

0

Sets the weight to trigger alarm indicating low fertilizer levels in lbs.

Row Fail Rate

2/1 (2 seeds

every 1 second)

Set to desired number of seeds per second to trigger seed sensor failure

alarm.

2

Step 5C only applies to those applications with a vari-

able rate kit option installed. Proceed to Step 6A if vari-

able rate is not applicable.

STEP 5C: Material Confi guration Setup

(Granular Seed or Fert Control)

16 different materials can be confi gured as seeding and fertilizer

controls. Material defaults on the Control Setup screen are Seed 1-4

(Granular Seed Control) Seed 5-8 (Granular Seed Monitor) Fert 1-4

(Granular Fertilizer Control) Fert 5-8 (Granular Fertilizer Monitor).

Reference the System Confi guration section in the Operator’s manual

for additional setup instructions.

Press the Control Setup button

.

At the Control Setup screen, select one of the 16 material buttons

to edit (labeled Seed 1-8 and Fert 1-8).

Enter desired values from Table D.

Press the Control Setup button

to return to the Control

Setup screen.

Repeat steps 2-4 for additional materials.

Press the Channel Setup button

to enter channel setup

constants.

1.

2.

3.

4.

5.

6.

TABLE D:

Material Setup

Gran Seed/Fert

Default Value/

Value to Enter Instructions/Defi nitions

Matrl Label

Seed 1/Fert 1

Material Name can be customized to accurately defi ne the material’s type.

Creating a name allows for quick identifi cation at the Material Summary

screen.

Type

Gran Seed/

Gran Fert Ctrl

Desired type of application control channel being used for a specifi c mate-

rial. The Material Type must correctly match the Control Type to be able to

select material from the Control Setup screen and operate properly.

Units

Lbs/Ac

Displays primary and secondary readout units in Lbs/ac or Kg/ha.

Target Rate

50 lbs/Ac

Desired rate of application in lbs/Ac.

Inc/Dec %

1%

Percent of change of the entered target rate change each time the Inc/Dec

button is pressed.

Max Rate

78 lbs

Max application rate in lbs per acre the control will allow.

Min Rate

48 lbs

Min application rate in lbs per acre the control will allow.

Density

60 lbs/ft

3

/bu

Establishes the density of material in lbs/ft

3

/bu.

# Towers

5

Establishes the number of towers for that channel.

Calibration

Constant

82500 Pul/ft

3

Number of pulses to drop 1 cubic foot/liter of material.

Variable Cal

Constant

Disabled

Adjusts the accuracy of the seed amount dispensed based on the seed

type. A selection of 25 pre-defi ned seed types are available.

Low Shaft RPM

1

Set to desired min meter RPM.

High Shaft RPM

50

Set to desired max meter RPM.

Prod Level Alarm

0

Sets the weight to trigger alarm indicating low fertilizer levels in lbs.

Row Fail Rate

2/1 (2 seeds

every 1 second)

Set to desired number of seeds per second to trigger seed sensor failure

alarm.

STEP 6A: Channel Setup (Granular Seed Monitor)

Channel 1 is generally used for granular seed monitor setup.

At the Channel Setup screen, verify that channel 1 is set to

granular seed monitor.

Enter desired values using Table E as reference.

To set up additional control channels (granular fert monitor,

granular fert control, granular seed control, RPM Control), press

the Next Channel button

.

When channel setup is complete, press the Work Screen button

to return to the Main Work screen.

Once a control channel has been established as granular seed

monitor, any new materials established as granular seed monitor

on the Material Setup screen will automatically be added as

optional materials for granular seed monitor channels on the

Control Setup screen.

1.

2.

3.

4.

TABLE E:

Channel Setup

Gran Seed Mon

Default Value/

Value to Enter Instructions/Defi nitions

Type

Gran Seed

Monitor

Set desired channel type as Gran Seed Monitor.

Material Name

Seed 5

Displays only materials that have been confi gured for the channel type.

Input Filter

50

Feedback frequency fi lter for the control channel. DO NOT CHANGE.

Sensor Constant

360

Sensor Constant establishes the number of pulses for one revolution of

the feedback sensor. If a DICKEY-john application rate sensor is used, the

value should be set to 360.0.

Gear Ratio

1.0

Specifys the actual ratio from the feedback sensor to the seed meter shaft

RPM. Number of revolutions the feedback sensor turns in relation to one

revolution the seed meter turns.

# of Seed Rows

(determined by row

spacing)

50 row

Entry of a specifi c number of seed rows to the control channel. Row

assignment is given a priority based on the channel and will be assigned

sequentially thereafter. Channel 1 is always assigned to the fi rst set of rows,

Channel 2 next set of rows, and so on.

65 row

80 row

Channel Width

480

Manual entry of the channel width for rows assigned to a specifi c channel.

Width calculation can be determined by # of seeder rows assigned to the

channel multipled by the row spacing.

Proceed to Step 6C if a variable rate kit is installed.