Great Plains CTA4000 Quick Start User Manual

Quick setup guide for intelliag model cta

11001-1459C-201107

©2011 DICKEY-john Corporation

Specifi cations subject to change without notice.

Quick Setup Guide for IntelliAg Model CTA

STEP 1: Pre-Programming Preparation:

Power on vehicle via ignition switch to activate Virtual Terminal (VT). Main menu will display pre-programmed default settings.

If errors are detected (e.g., failed sensors, incorrect confi guration) an alarm and code will display. Alarms are silenced by pressing the Alarm Cancel button

. Refer to Operator’s

manual for troubleshooting assistance.

The system has three user levels. The system loads in user level 1 (operator level) at every power cycle. Access to user level 2 and 3 screens to setup constants (system confi guration)

requires a password available through an authorized Great Plains dealer.

1.

2.

3.

The Quick Setup Guide assumes the Virtual Terminal, Working Set Master Module, Working Set Member Module, and all sensors

have been connected and properly installed. Quick Setup Guide assumes channel 1 (front bin) to be seed and channel 2 (rear

bin) to be fertilizer. Reference the Operator’s manual for installation instructions.

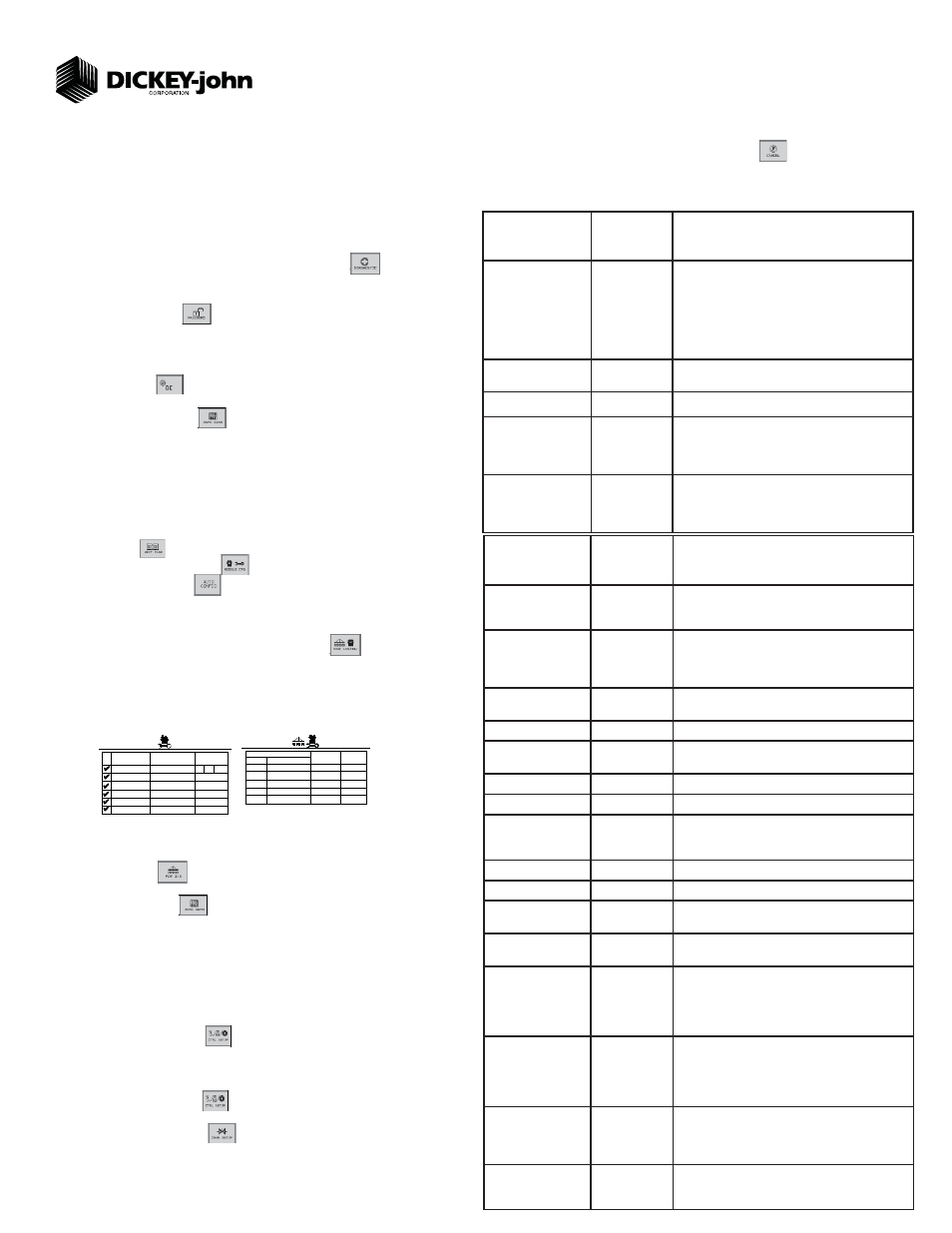

STEP 3: Auto Confi guration (identifi es sensors connected to each module)

Auto confi g is performed at the factory, but may need to be done in the fi eld as changes

are made to the system or if options are added to the base system.

Verify Auto Confi g results are correct. Check that the correct number of rows are assigned to

the correct module and number of hoppers and pressure sensors are assigned accurately.

To Run Auto Confi g:

Press Next Page

until Module Confi guration button appears.

Press Module Confi guration button

.

Press AUTO CONFIG button

.

Hour glass will indicate system is detecting the presence of seed, pressure, or hopper

sensors connected to each module and automatically assigns to the appropriate module.

When Auto Confi g completes, press the Row Assign button

to display the Row

Assignment screen to verify correct Row # is assigned to the correct module based on serial

number.

Enter # of rows assigned to each module.

1.

1.

2.

3.

4.

5.

6.

STEP 5A: Material Confi guration Setup (Granular Seed Monitor)

16 different materials can be confi gured as seeding and fertilizer controls. Material defaults on

the Control Setup screen are Seed 1-4 (Granular Seed Control) Seed 5-8 (Granular Seed

Monitor) Fert 1-4 (Granular Fertilizer Control) Fert 5-8 (Granular Fertilizer Monitor).

Reference the System Confi guration section in the Operator’s Manual for additional setup

instructions.

Press the Control Setup button

.

At the Control Setup screen, select one of the 16 material buttons to edit (labeled Seed 1-8

and Fert 1-8).

Enter desired values from Table B.

Press the Control Setup button

to return to the Control Setup screen.

Repeat steps 2-4 for additional materials.

Press the Channel Setup button

to enter channel setup constants.

1.

2.

3.

4.

5.

6.

TABLE B:

Gran Seed Mon

Material Setup

Default Value/

Value to Enter Instructions/Defi nitions

Matrl Label

Seed 5

Material Name can be customized to accurately defi ne

the material’s type. Creating a name allows for quick

identifi cation at the Control Setup screen.

Type

Gran Seed

Monitor

Desired type of application control channel being used

for a specifi c material. The Material Type must correctly

match the Control Type to be able to select material from

the Control Setup screen and operate properly.

Display Units

Lbs/Ac

Displays primary and secondary readout units in Lbs/Ac

or Kg/ha.

Target Rate

60 lbs

Desired rate of application in lbs/Ac.

Density

60 lbs/bu

Establishes the density of material. Density units can be

entered in lbs/bu or lbs/ft

3

.

# of Towers

5

Establishes the number of towers for that channel.

Calibration Constant

77600 Pul/Ft

3

Number of pulses to drop 1 cubic foot/liter of material.

Variable Cal Constant

Disabled

Adjusts the accuracy of the seed amount dispensed

based on the seed type. A selection of 25 pre-defi ned

seed types are available.

Low Shaft RPM

1

Set to desired min seed meter RPM.

High Shaft RPM

50

Set to desired max seed meter RPM.

Prod Level Alarm

0

Sets the weight to trigger alarm indicating low seed levels

in lbs.

Seeds per Pound/Kg

3000 Lb

Converts the current application rate from Lb/ac to KS/Ac

to determine population and population alarms.

High Pop Alarm

20%

This is the percentage above the target population of

the seeder channel if rows are assigned to the seeder

channel. If rows are not assigned to a seeder, this is

the percentage above average seeder population for all

unassigned rows.

Low Pop Alarm

20%

This is the percentage below the target population of the

seeder channel if rows are assigned to the seeder chan-

nel. If rows are not assigned to a seeder channel, this is

the percentage below average seeder population for all

unassigned rows.

On/Off Pattern

Every Row On

On/Off Pattern indicates specifi c row patterns to be on

or off. Select pre-defi ned seeder All Row On pattern.

For other pre-defi ned seeder patterns or individual row

settings, reference Operator’s manual.

Row Fail Rate

2/1

Sets the threshold for row failure alarms. Entered in

seeds per second. 2/1 is a row failure threshold of 2

seeds in 1 second.

STEP 4: Row Status/Row Width Setup

Press Row I/O button

.

Enter desired values using Table A as reference.

Press Work Screen button

to return to the Main Work screen.

1.

2.

3.

1

# O F

R O W S

MODULE

ADDR.

TYPE

R O W

# ’ s

1 - 1 0

WSMB-18R

1 0

Seed Sensor Configuration Screen

11 - 2 0

S E R I A L

N U M B E R

1

M O D U L E

T Y P E

M O D U L E

A D D R .

WSMB-18R

WSMT-ACCGP

2

10001

10003

WSMB-18R

3

3

WSMB-18R

4

2 1 - 3 0

10004

WSMB-18R

4

10002

Module Configuration Screen

10005

10006

WSMB-18R

WSMB-18R

6

5

5

WSMB-18R

WSMB-18R

WSMB-18R

1 0

1 0

1 0

3 1 - 4 0

4 1 - 5 0

1 0

6

2

Above screens depict setup for 50 row.

For 65 row (# of Rows = 13)

For 80 row (# of Rows = 16)

TABLE A: Row

Status/Row Width

Setup

Default Value/

Value to Enter Instructions/Defi nitions

Row Width

(50 row)

10

Enter row width distance in inches to calculate seed rate

data.

Row Width

(65 row)

7.5

Row Width

(80 row)

6.0

Auto Update Width

Disabled

When enabled, implement width will automatically calcu-

late. If disabled, manually enter implement width.

Implement Width

480

Manually enter implement width in inches.

On/Off Pattern

Every row on

On/Off Pattern indicates specifi c row patterns to be on

or off. Select pre-defi ned seeder All Row On pattern.

For other pre-defi ned seeder patterns or individual row

settings, reference Operator’s Manual.

Pop/Block Pattern

Every row

blockage

Determines which sensors are used to calculate popul-

tion and those used only for blockage detection. Select

pre-defi ned Every Row Blockage. For other pre-defi ned

patterns, reference Operator’s Manual.

Proceed to Step 5C if a variable rate kit is installed.

STEP 2: Change User Level to Dealer Level

To change the user level, a 6-digit password is required. Password includes the fi ve-digit

serial number found on the label of the working set master or Information screen.

On the IntelliAg Main Work screen, press the Diagnostics button

.

At the Diagnostics screen, press the Information button

At the Information screen, record serial number of WSMT.

Press the Password button

.

On the Password screen, enter the 6-digit password as follows: enter the fi rst digit as 2 for

User Level 2. For the next fi ve digits, enter the Working Set Master serial number taken from

the WSMT or Information screen.

Press the OK button . “Dealer screens on” appears at the bottom of screen confi rming

the password and dealer screens are activated.

Press the Work Screen button to return to the Main Work screen.

1.

2.

3.

4.

5.

6.

7.