Great Plains 3N-30P SE Assembly Instructions User Manual

Page 6

196-304m

10/7/2004

Great Plains Mfg., Inc.

Monitor System Option

6

Assembly Instructions for 196-302A 15 inch and Twin Row Spacing

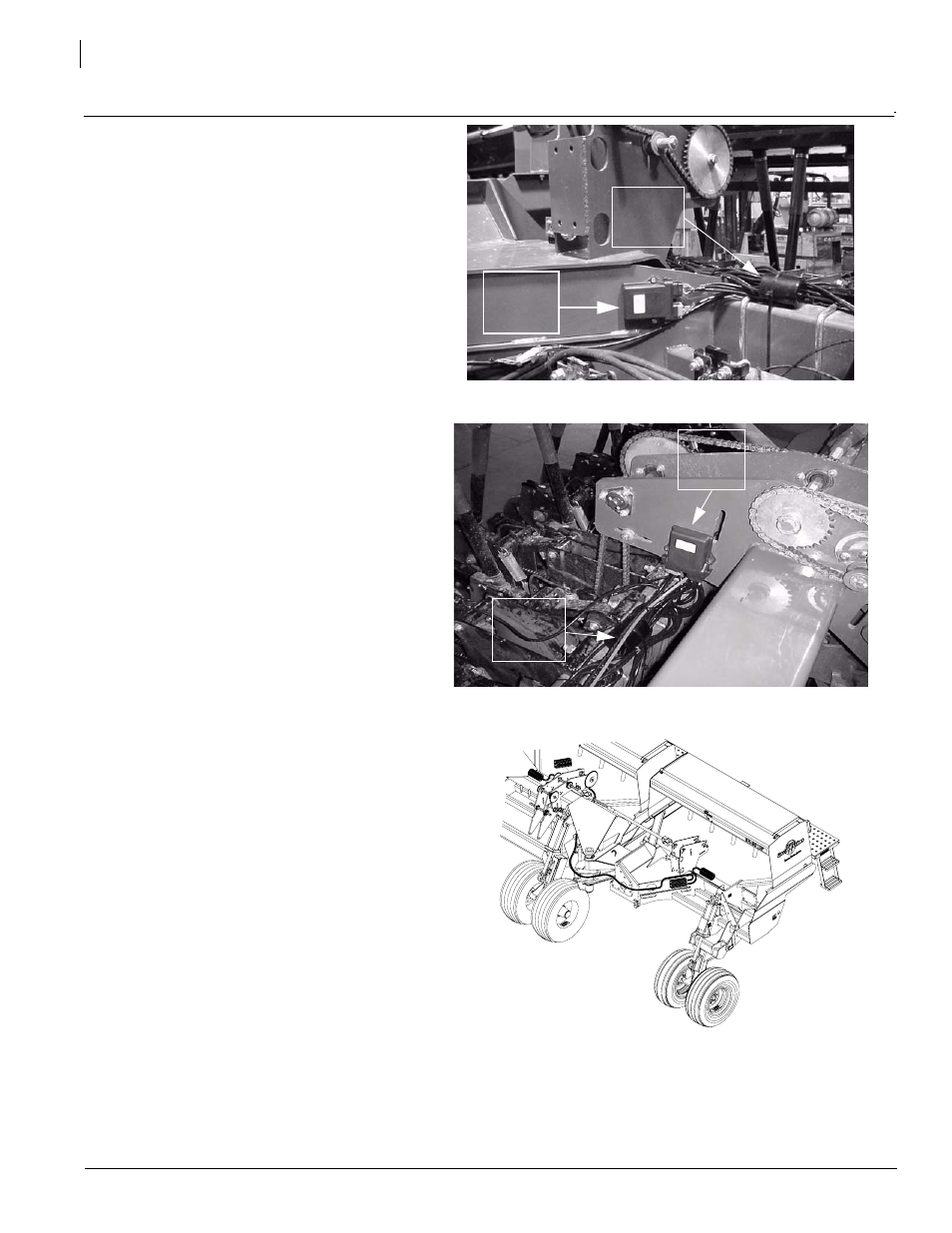

Refer to Figures 7 and 8

1.

Mount one each of the material flow modules to

the wing frame as shown in figure 1. Mount one

material flow module, on the left-hand side of

the center frame using 1/4" x 1 1/2" bolts and

1/4" lock nuts as shown.

NOTE

:

If there are no predrilled holes in the frame

use the templates provided, mark and drill 5/16”

holes for mounting the module. (Template on pages

9 & 10)

2.

Place the harness wire bundle on the frame by

the material flow module. Connect the wire ex-

tensions to the openers starting at the left side

of the drill in numerical order. Wire extension

number 1 with first opener on the left. Continue

in the same manner until all wire extensions are

connected. Fasten the harness to the frame with

cable ties.

3.

Connect black and gray colored leads into the

material flow modules. Inlets are color coded.

Black to black and gray to gray.

Refer to Figure 9

4.

Attach sensor lead marked IN from the wing

frame harness to the 15’ smart sensor exten-

sion wire. Route the 15’ extension using the

same path as the opener lift hoses allowing the

same slack at the drill toolbar pivots as the other

hoses. Connect this extension to the center

frame harness lead marked OUT. Use cable ties

to secure the wires in place.

5.

Attach the 40’ seed smart extension to the cen-

ter frame harness sensor lead marked IN. Put

cable plugs in the OUT leads of the wire cable

harness. Route the 40’ extensions through the

tongue tube up to the tractor. A 40’ extension is

used from P1 to the right-hand wing module.

Only the P1 port is used. A 30’ extension con-

nects the right-hand wing to the center frame

module and a 15’ extension connects the center

module to the left-hand wing module.

NOTE: Left-hand side of drill is shown in figures.

6.

Refer to page 7 for a detailed listing of parts and

schematics for this particular monitor system.

7.

For console assembly, speed sensor and other

schematics illustrations refer to the DJ manual

found in the monitor system package.

8.

Refer to page 8 for speed sensor instructions if

sensor is being used.

19217

Harness

Wire

Bundle

Harness

Wire

Bundle

Figure 9

Routing for wire Harness

19255

Figure 8

Center Drive System Frame

Figure 7

Wing Frame

19218

Material

Flow

Module

Material

Flow

Module

Harness

Wire

Bundle

NOTE: J1 accessory harness and 40’ extension are

not used if speed sensor on drills is not used.