Hydraulic connectors and torque – Great Plains 4000TM Assembly Manual User Manual

Page 44

40

1800-3000TM

Great Plains Manufacturing, Inc.

586-536E

04/12/2013

Hydraulic Connectors and Torque

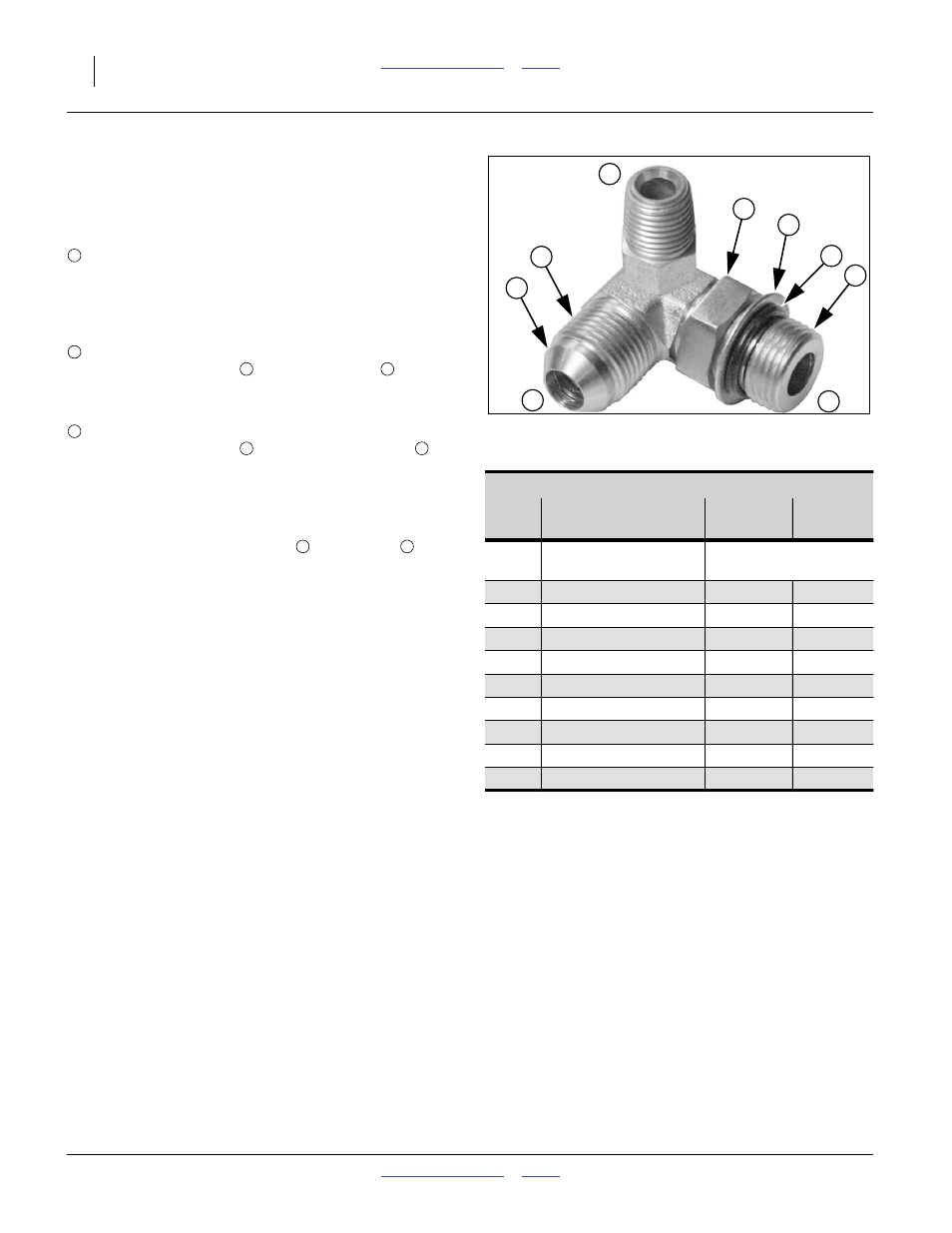

Refer to Figure 37 (a hypothetical fitting)

Leave any protective caps in place until immediately prior

to making a connection.

NPT - National Pipe Thread

Note tapered threads, no cone/flare, and no O-ring.

Apply liquid pipe sealant for hydraulic applications.

Do not use tape sealant, which can clog a filter and/or

plug an orifice.

JIC - Joint Industry Conference (SAE J514)

Note straight threads

and the 37

° cone on

“M” fittings (or 37

° flare on “F” fittings).

Use no sealants (tape or liquid) on JIC fittings.

ORB - O-Ring Boss (SAE J514)

Note straight threads

and elastomer O-Ring

.

Prior to installation, to prevent abrasion during tight-

ening, lubricate O-Ring with clean hydraulic fluid.

Use no sealants (tape or liquid) on ORB fittings.

ORB fittings that need orientation, such as the ell

depicted, also have a washer

and jam nut

(“adjustable thread port stud”). Back jam nut away

from washer. Thread fitting into receptacle until

O-Ring contacts seat. Unscrew fitting to desired

orientation. Tighten jam nut to torque specification.

2

5

4

9

8

7

5

3

Figure 37

Hydraulic Connector ID

31282

Fittings Torque Values

Dash

Size

Fitting

N-m

Ft-Lbs

-4

1

⁄

4

-18 NPT

1.5-3.0 turns past finger

tight

-5

1

⁄

2

-20 JIC

19-20

14-15

-5

1

⁄

2

-20 ORB w/jam nut

12-16

9-12

-5

1

⁄

2

-20 ORB straight

19-26

14-19

-6

5

⁄

16

-18 JIC

24-27

18-20

-6

5

⁄

16

-18 ORB w/jam nut

16-22

12-16

-6

5

⁄

16

-18 ORB straight

24-33

18-24

-8

3

⁄

4

-16 JIC

37-53

27-39

-8

3

⁄

4

-16 ORB w/jam nut

27-41

20-30

-8

3

⁄

4

-16 ORB straight

37-58

27-43

1

1

2

4

5

3

5

7

8

9