Wing & lift assembly – Great Plains 4000TM Assembly Manual User Manual

Page 18

14

1800-3000TM

Great Plains Manufacturing, Inc.

586-536E

04/12/2013

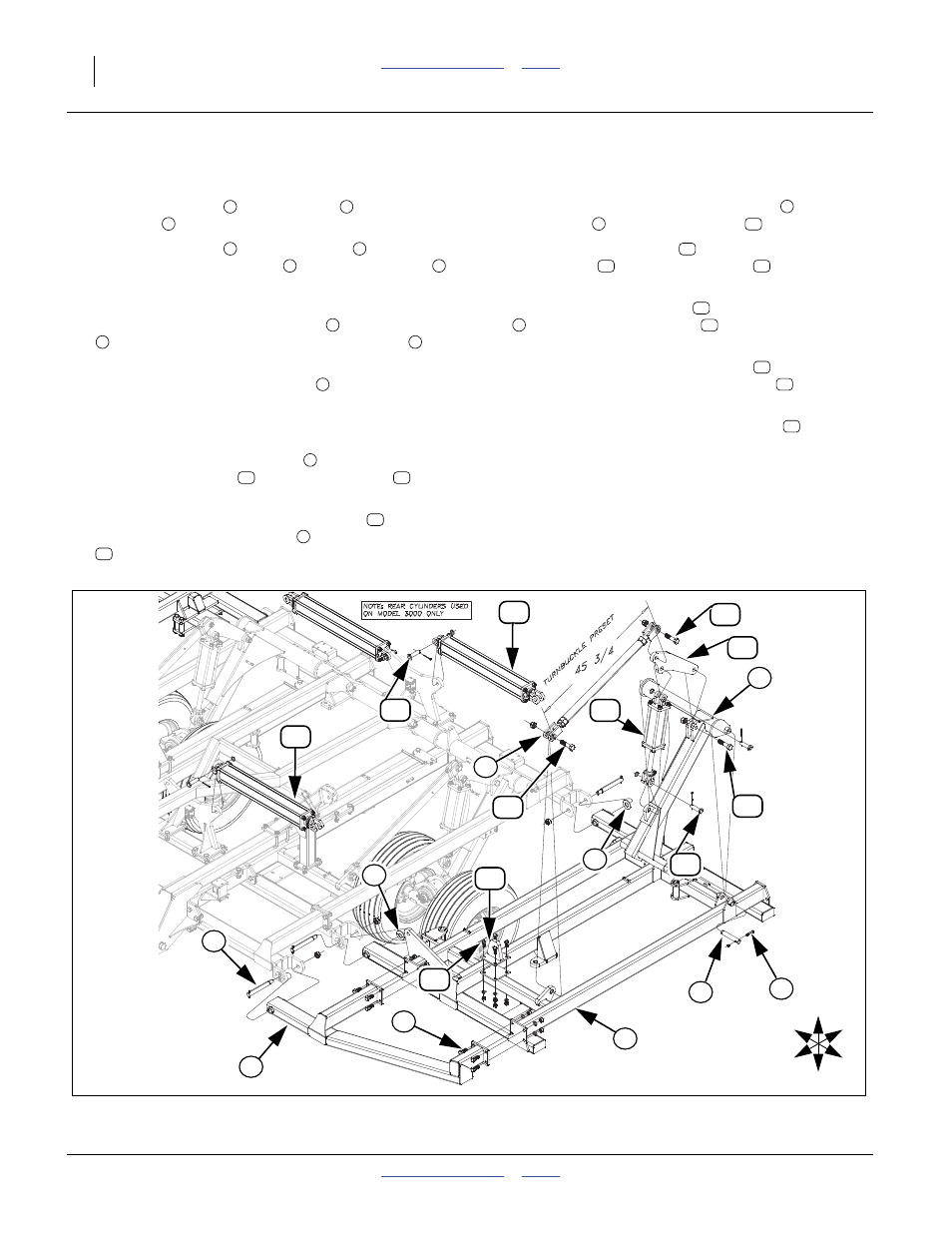

Wing & Lift Assembly

Refer to Figure 13

46. Attach wing brace

to wing frame

with 3/4 x 2

hex bolts

, 3/4 lock washers and 3/4 nuts.

47. Attach wing brace

and wing frame

to center

frame with wing hinge pins

, 1 1/4 flat washers

(rear side of wing hinge tubes only, do not use

washer on wing brace bar) and 1 lock nuts.

48. Install lh and rh wing wheel arms

with 1 x 7 pins

, 3/8 x 2 1/4, Gr. 8, special thread hex bolts

and

3/8 nylon lock nut.

Note: Be sure turnbuckle assembly

is preset at 45 3/

4” before installing as shown below. See gang

angle adjustment in “Operator Manual” before

going to field.

49. Install wing wheel turnbuckles

to front, top hole, of

cylinder mount plate

with 1 x 4 hex bolts

and 1

lock nuts.

50. Install rear hole of cylinder mount plate

to inside

of plates of wing wheel arms

with 1 x 4 hex bolts

and 1 lock nuts.

51. Secure front of wing wheel turnbuckles

to plate on

wing frame

with 1 x 4 hex bolts

and 1 lock nuts.

52. Install wing lift cylinders

(base end to cylinder

mount plate

) with 1 x 3 1/8 pins

, 1.5 x 1.0

x.075 machine washers and 3/16 x 2 cotter pin.

53. Attach wing stop brackets

to plate of wing frame

with 5/8 x 1 1/2 hex bolts

, 5/8 lock washers and

5/8 nuts.

54. Now the base end of fold cylinders

may be

hooked up with the 1 x 3 1/8 clevis pin

, 1.5 x 1.00

x 0.075 machine washer and 3/16 x 2 cotter pin.

55. Do not hook up rod end of fold cylinder

until sys-

tem is purged of air. See “Purging Hydraulic Sys-

tem” on page 18.

56. Tighten all bolts with lock nuts snug, but do not

torque. The rest of the bolts may be tightened to

specs, See “Torque Values Chart” on page 38.

1

2

3

1

2

4

5

6

7

8

9

9

10

11

10

6

11

9

2

11

12

10

13

14

2

15

16

13

16

U

D

F

B

L

R

5

7

Figure 13

Wing & Lift Assembly

42959

3

1

4

8

11

2

5

9

6

10

11

11

12

13

14

15

16

16

13