Section 8 specifications and capacities, Loup electronics monitor technical specifications, Specifications and capacities – Great Plains ADC1150 Operator Manual User Manual

Page 53

51

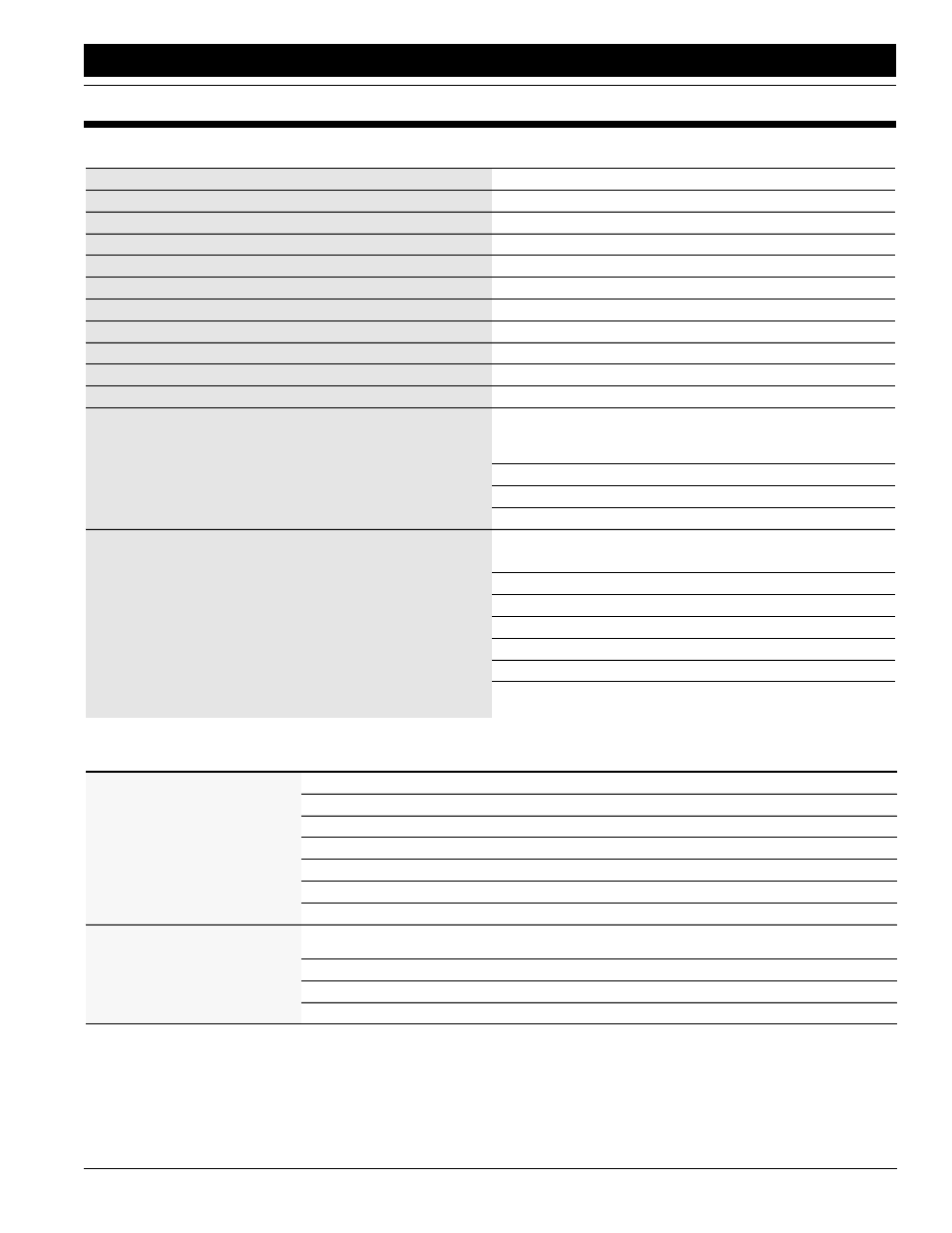

Section 8 Specifications and Capacities

6/15/05

ADC1150 Air Drill Cart 167-101M

Great Plains Mfg., Inc.

Section 8

Specifications and Capacities

Capacity

150 bu (5285.86 L)

Overall Width

10 ft 8 in (3.25 m)

Overall Height

10 ft 6 in (3.20 m)

Length Front To Rear with Auger

18 ft 10 in (5.74 m)

Weight, Empty

4,500 lb (2041.17 kg)

Weight, Fully Loaded

14,100 lb (6395.65 kg)

Tire Size

16.5L by 16.1 10 ply, rib implement

Ground Clearance Below Meters

23 in (58.42 cm)

Maximum Fan Speed

5000 rpm

Seeding Rates

2 to 230 lb per acre (22.40 to 257.80 kg per hectare)

Drive

Electric clutch with automatic height switch

Tractor Power Requirements

(Horsepower needed will vary with conditions, terrain and row spacing.)

with ADI334

180 hp

with ADI345

240 hp

with NTA3010

250 hp

with NTA3510

275 hp

Tractor Hydraulic Requirements

with ADI334 or ADI345

Load-sensitive or closed-center hydraulics

Capacity of 15 to 30 gallons per minute at 2000 pounds per square inch

Three sets of hydraulic outlets

with NTA3010 or NTA3510

Three sets of hydraulic outlets

Capacity of 15 to 30 gallons per minute at 2000 pounds per square inch

Load-sensitive or closed-center hydraulics

Equipped so a return line can be plumbed directly to the tractor hydraulic

reservoir

Loup Electronics Monitor Technical Specifications

Fan RPM

Fan rpm is displayed when FAN is selected

The input signal is from a smart high speed sensor.

The range is 0-9990 rpm with a resolution of 10 rpm.

The number of pulses per revolution on the fan can be set from zero (function disabled) to four.

The low alarm point is user adjustable between zero and the high rpm alarm point.

The high alarm point is user adjustable between the low alarm point and 9900 rpm.

Response time to an alarm condition is 1 second maximum.

Shaft RPM

Three shaft speeds (front, rear and auxiliary) are monitored. Shaft speeds are displayed when the appro-

priate function is selected.

The input signal is from a smart shaft sensor.

The number of pulses per revolution on the shaft can be set from zero (function disabled) to 10.

Shaft alarm generation will be delayed 30 seconds if ground speed is below 2 mph.