Treader adjustment, Treader angle adjustment, Treader adjustment treader angle adjustment – Great Plains 9756PP Operator Manual User Manual

Page 24

20

9322-9756PP

Great Plains Manufacturing, Inc.

580-043M

02/17/2014

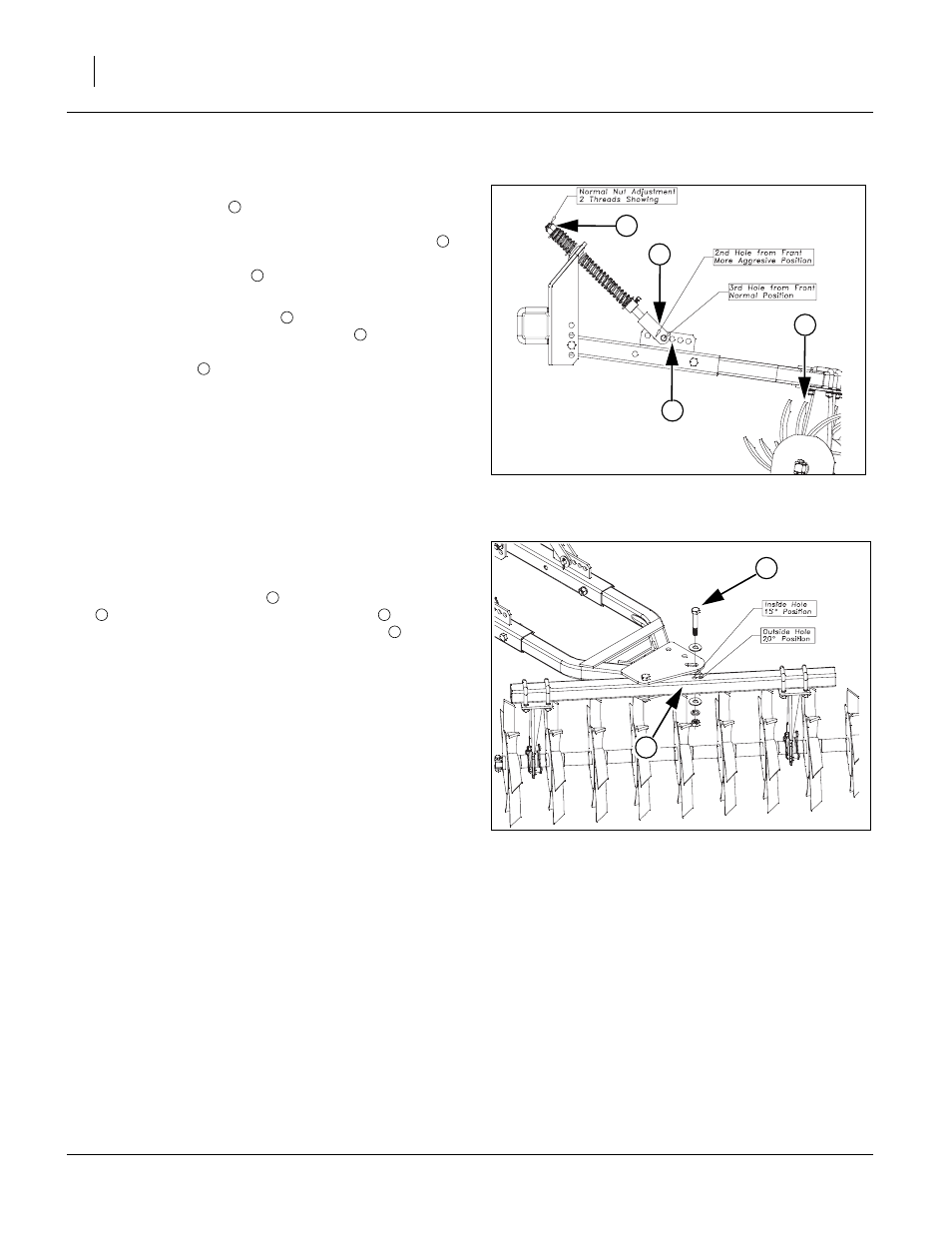

Treader Adjustment

Refer to Figure 11

35. Adjust the treaders

to leave the desired result. In most

cases the treader should be allowed to float and will not

require additional down pressure. The spring bolt

should be pre-set in the 3rd hole (normal position) of

treader mount bracket

.

36. To increase down pressure and make the treaders more

aggressive, the spring bolt

may be moved forward to

the 2nd hole of treader mount bracket

, from front. This

will also reduce transport height so you may need to

tighten the nut

at the top of the spring bolt to raise the

treaders up slightly for transport.

Treader Angle Adjustment

Refer to Figure 12

37. The treaders are designed to be run at angles of either

15

° or 20°. 15° is the preferred setting in most instances.

To set the treader gangs

to 15

°, install the 3/4 x 4 bolt

in the inside hole of treader gang tube

. For 20

°,

install in outside hole of treader gang tube

.

38. If plugging of the treaders occurs, they may need to be

moved back one hole in the wishbone arm assemblies.

The further back you move these the more tail heavy the

unit is. Do not move them unless absolutely necessary.

Note: Most of the extra mounting holes in the brackets are

needed to allow our treaders to be mounted on com-

petitors machines. Under most circumstances, it is not

necessary to vary the settings from the factory recom-

mended settings for our machines.

Figure 11

Treader Adjustment

43013

2

4

3

1

1

2

3

2

3

4

Figure 12

Treader Angle Adjustment

43041

1

2

1

2

1

1