Depth stop, Wheel arm, Depth stop wheel arm – Great Plains 9756PP Operator Manual User Manual

Page 23

Great Plains Manufacturing, Inc.

Operating Instructions

19

02/17/2014

580-043M

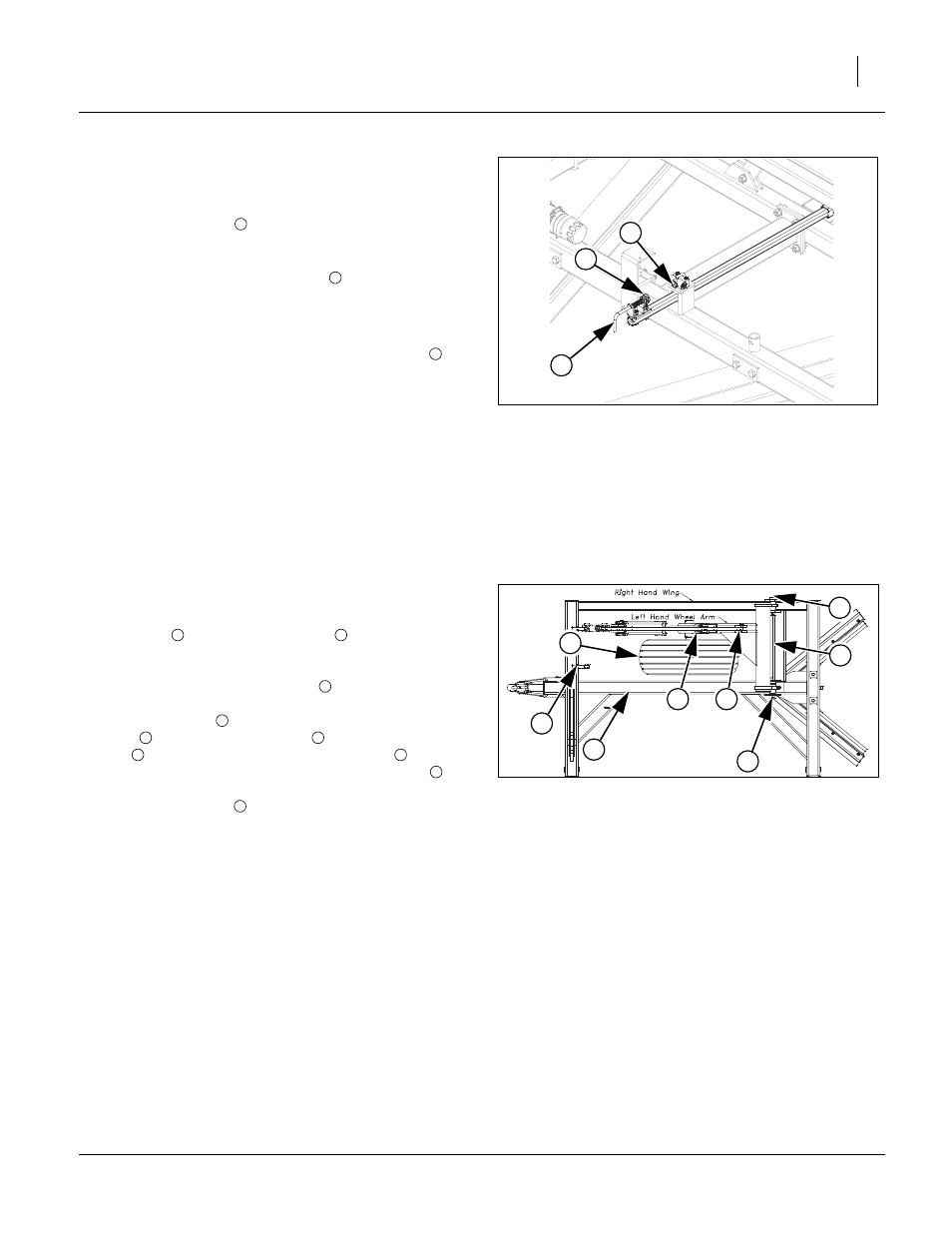

Depth Stop

Refer to Figure 9

.

33. Once the machine is level and set to the desired depth,

set the depth stop

at the front of the machine to

ensure that the unit will operate at a consistent depth

every pass. After setting the stop, if a change of depth is

desired, 1 full turn of the handle

either in or out will

change the depth approximately 1/4” up or down respec-

tively.

Note: If after setting the depth stop, the detent on the tractor

kicks out before the stop contacts the button

on the

depth stop, slow the hydraulic flow speed down. If this

problem persists, contact the factory service represen-

tative for other possible adjustments. On tractors with a

timed detent setting, set the detent so when you raise

the machine, the pump will run for 1/2 to 1 full second

after full raise. If it runs longer than this, damage to the

seals of the lift cylinders may result. If the problem still

persists, contact the factory service representative for

the possible adjustments.

Note: Do not try to adjust the rebound valve without contact-

ing the factory service rep.

Wheel Arm

Refer to Figure 10

34. If the tire

on the outside wings

, on models 9533,

9744 and 9748, are riding in loose or already worked

ground and running too deep, you can correct the prob-

lem by moving the wheel arms

to the optional position

as shown. Start by lowering machine to ground until

wheel arm pins

are loose. Remove both wheel arm

pins

, rear cylinder arm bolt

, and rod end cylinder

pin

. Switch the RH and LH wheel arms

side to side

and move wheel arm linkage over to inside lug

on

front of frame. Re-install all pins and bolts to secure. This

will move the tires

inward 5” to let wings run level.

1

2

Figure 9

Depth Stop Adjustment

42250

3

1

2

3

2

Figure 10

Wheel Arm

41347

1

4

4

3

6

5

7

1

2

3

4

4

5

6

3

7

1