Gauge wheel adjustment, Thread protectors, Gauge wheel adjustment thread protectors – Great Plains 4336 DH Operator Manual User Manual

Page 28

24

3323-4336DH

Great Plains Manufacturing, Inc.

556-100M

05/22/2012

Gauge Wheel Adjustment

Refer to Figure 19

7.

To change the gauge wheel

setting, remove the wire

retaining pin

and fold gauge wheel crank

up to

adjust.

8.

Lower or raise the gauge wheel by turning the gauge

wheel crank

. Raise the gauge wheels up until the

disk is adjusted in the fore-and-aft, side-to-side and to

the desired working depth you desire.

9.

Fold the gauge wheel crank

back down in the field

position and reinstall the wire retaining pin

.

10. As you are running the disk through the field, stop the

tractor leaving the disk in the ground. Now adjust the

gauge wheels

1/2” to 1 1/2” above the ground.

11. After initial adjustment, turn gauge wheel crank

the

same amount as the depth stop crank (if changed, but

crank turns opposite way than depth stop crank to keep

initial setting).

12. This position should be maintained to prevent exces-

sive wear to gauge wheel parts.

Note: Tractor Speed: The ideal working speed for the disk

harrow is 5 to 6 mph. Working too slow may cause

plugging, poor incorporation or mixing of crop residue

and reduced weed kill. Running too fast may cause

streaks in chemical incorporation and ridging.

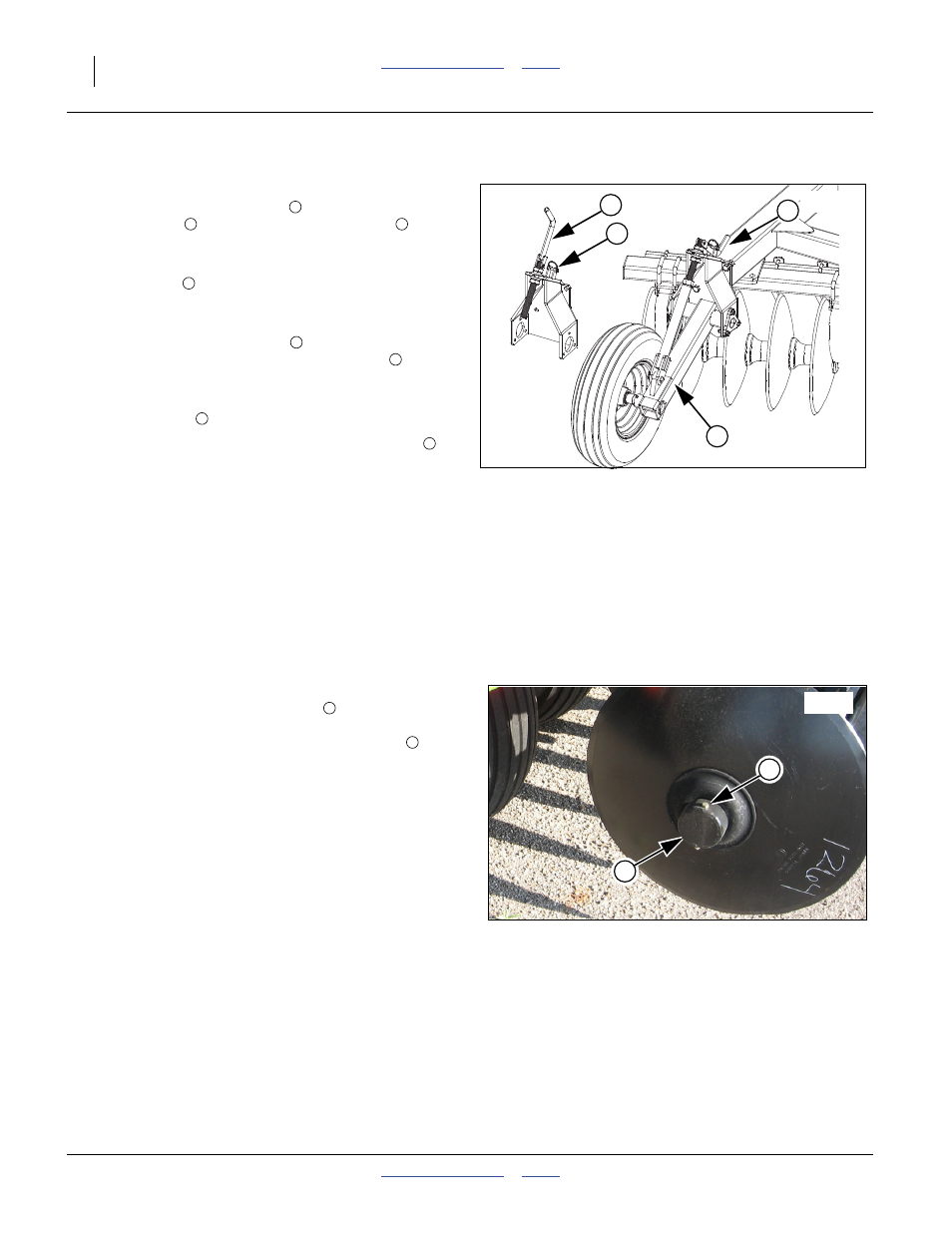

Thread Protectors

Refer to Figure 20

13. Make sure thread protector bolts

are in place and

tight. Gang bolt thread damage may occur at hinge

point when gangs flex without protector caps

. Lost

caps with no bolt may allow gang nut to become loose.

Figure 19

Gauge Wheel

41619

3

1

2

4

1

2

3

3

4

2

1

3

Figure 20

Thread Protector

42126

1

2

1

2