Scraper adjustment – Great Plains 4336 DH Operator Manual User Manual

Page 22

18

3323-4336DH

Great Plains Manufacturing, Inc.

556-100M

05/22/2012

Note: Once the disk is level from side to side, it must be lev-

eled from front to rear. With the self leveling hitch, once

the disk is set for the tractor it will be level at any depth.

27. Again lower the disk to 1-2” above the ground. Adjust

the turnbuckle

by loosening the jam nut

with turn-

buckle wrench provided on machine. Adjust turnbuckle

by turning the turnbuckle assembly

with turnbuckle

wrench until front blades are about 1/2” closer to the

ground than the rear blades.

28. Re-tighten the jam nut on turnbuckle.

Note: Once the disk is level from side to side, it must be lev-

eled from front to rear. With the self leveling hitch, once

the disk is set for the tractor it will be level at any depth.

29. Again lower the disk to 1-2” above the ground. Adjust

the hitch cylinder so that the front blades are 1/2”

closer to the ground than the rear blades.

30. The lock valve

will lock this length in.

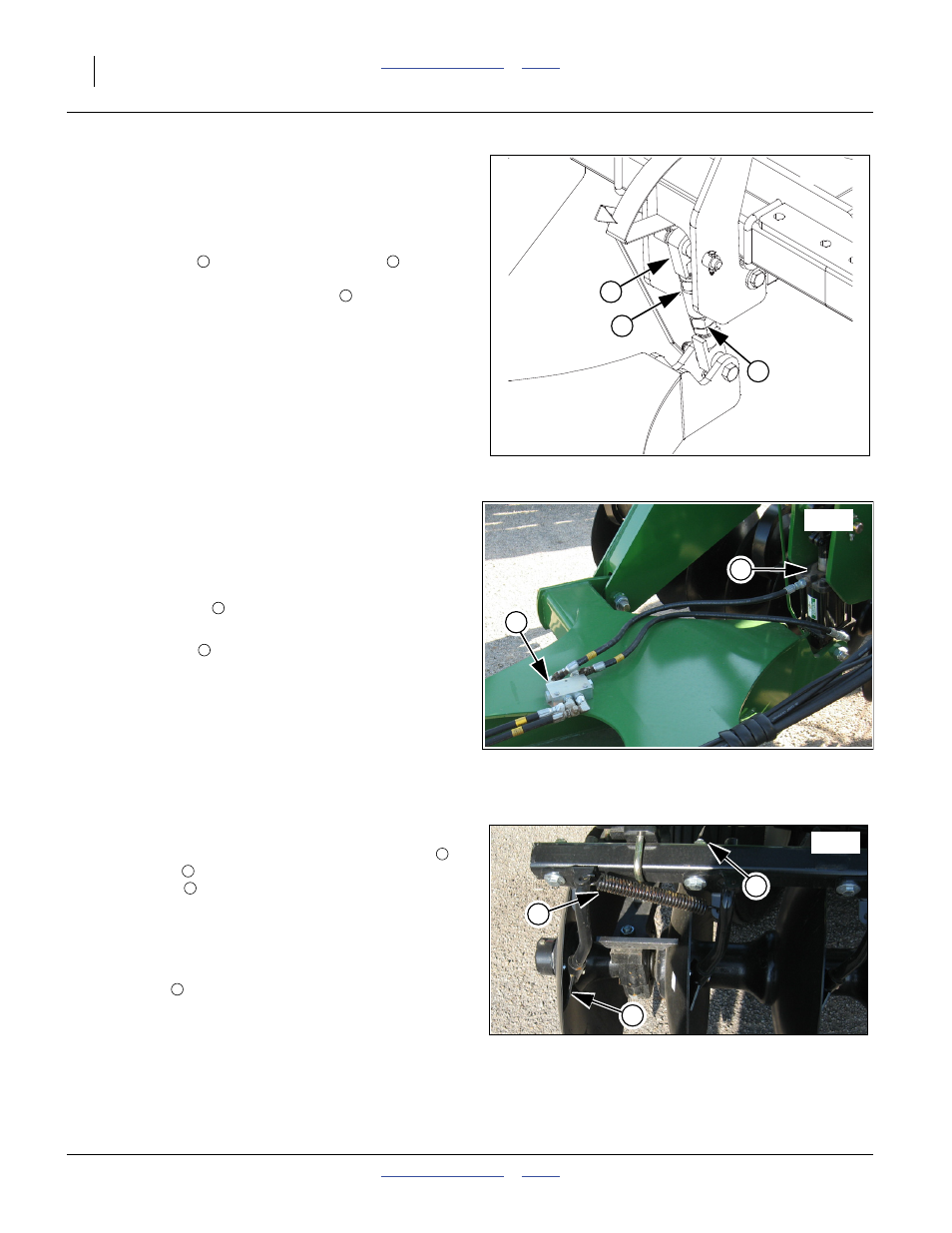

Scraper Adjustment

31. For rigid scraper adjustment, loosen 1/2” lock nut

,

allow spring

to move scraper against blade, retighten

1/2” lock nut

.

Note: Running scraper in rigid position away from the disc

blade could result in premature scraper wear and plug-

ging.

32. For self-adjusting operation of spring scrapers, loosen 1/

2” lock nut

several turns. This will allow the spring ten-

sion to hold scraper against disc blade.

Figure 13

Hitch Turnbuckle Leveling

42124

3

2

1

1

2

3

Figure 14

Hitch Cylinder Leveling

42114

4

5

4

5

Figure 15

Spring Scraper Adjustment

42116

1

2

3

2

3

2

2