Normal field operations – Great Plains Max Cover Verti-Till Ripper Operator Manual User Manual

Page 29

8/6/07

596-098M

27

Operating Instructions

Normal Field Operations

For drills with S/N: 1025MM and below.

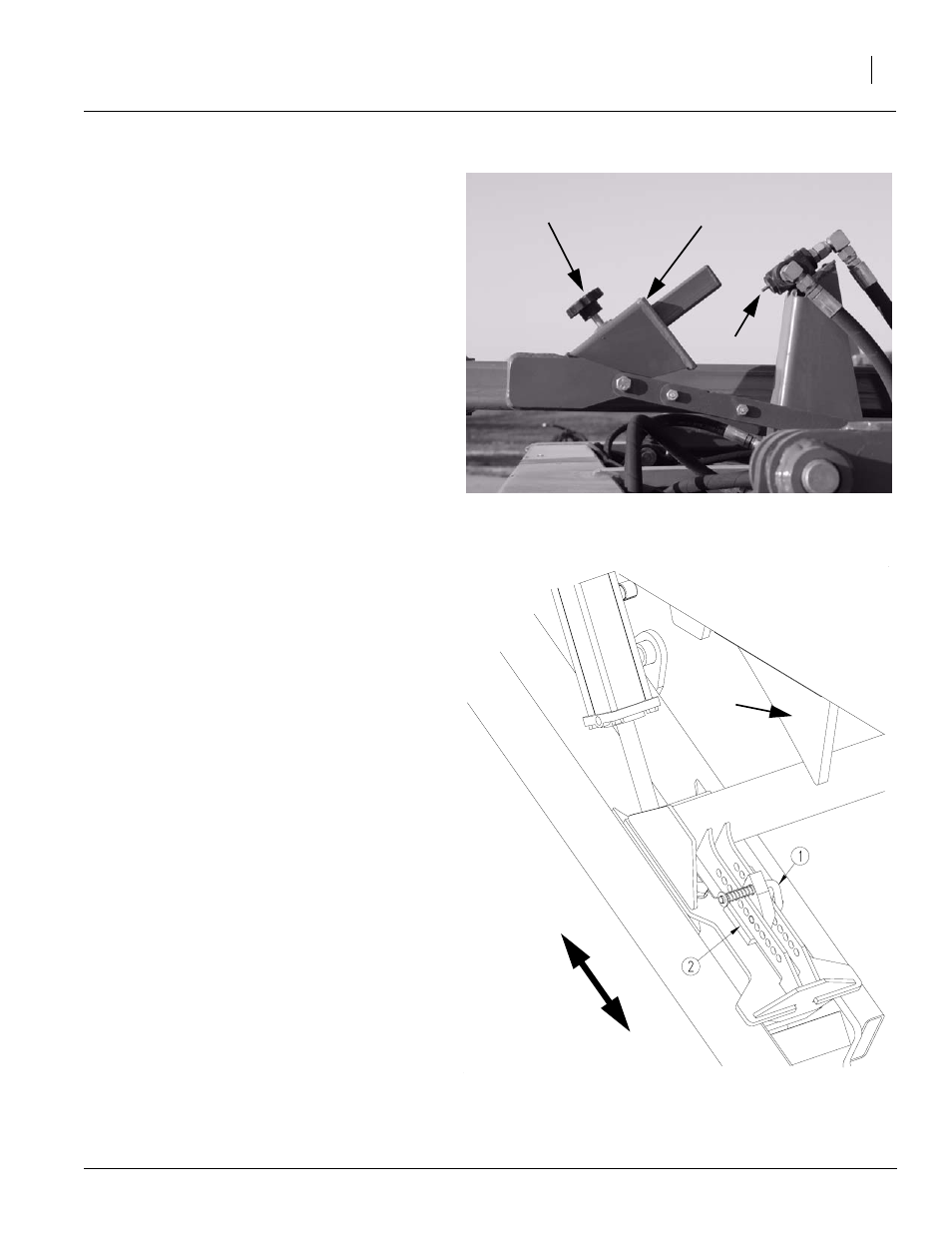

Refer to Figure 18

1.

Lower the frame to a desired tillage depth. The

depth control paddle can be pushed up against

the depth control valve stem and locked with

the knob. The unit will automatically stop at this

depth each time the unit is lowered.

For drills with S/N: 1026MM and above.

Refer to Figure 19

1.

Raise the implement fully and install the cylin-

der locks, see “Lock Cylinders,” page 28. Pull

the spring loaded pin (1) and slide the move-

able depth stop (2) to achieve desired tillage

height and re-engage pin. The top hole allows

for a 16” tilling depth and the lower hole allows

for a 6” tilling depth. Repeat for opposite wheel

arm.

NOTE: Be sure the lock pins are set in the same

holes on both wheel arms.

2.

Adjust the coulters up or down to achieve dif-

ferent tilling, cutting and mixing results. A pilot

operated check valve in the coulter lift circuit

will lock the coulters at the depth you choose.

3.

Always lift the unit out of the ground when turn-

ing at field ends and other short radius turns to

avoid damage and premature wear to the

shanks and coulter gangs.

4.

Both the Auto reset and Rigid shank mounts

are protected by shear bolts for extreme over-

loads. If the shank bolt shears replace the low-

er bolt with the correct shear bolt, use GP part

number 802-060C. (HHCS 5/8-11 x 4 Gr5)

Note: For your convenience a series of holes in 4

gussets on the rear of the machine have been pro-

vided for spare shear bolt storage.

Figure 18

Depth Control Paddle

21660

Knob

Paddle

Valve Stem

Deep

16”

Shallo

w

6”

Frame

Bumper

Figure 19

Manual Depth Stop

22563