Section 4: maintenamce & lubrication, Maintenance & lubrication, Section 4 maintenance & lubrication – Great Plains VT7300 Operator Manual User Manual

Page 11: General maintenance, Lubrication

Section 4: Maintenamce & Lubrication

6/30/2008

Verti-Till VT5300-VT9225 Finishing Attachments 596-156M

9

Maintenance & Lubrication

1. Always use the transport lock when

working or doing maintenance on the

seedbed conditioner. Read and

understand all safety decals on your

equipment.

2. During the first season of operation, and

periodically after that, check your bolts for

tightness.

3. Check wheel bearings occasionally for

excessive endplay.

4. Replace or rotate worn parts as needed—

bolts, clevis pins, bearings, chisel points

etc...

5. Check and tighten or replace any

hydraulic leaks. Check hoses for any

leaks. It is important that there are no

leaks on the equipment.

6. Grease reel bearings and wheel

bearings sparingly. Over greasing may

cause damage to seals and reduce the

life of the bearing. Grease hinge points

periodically.

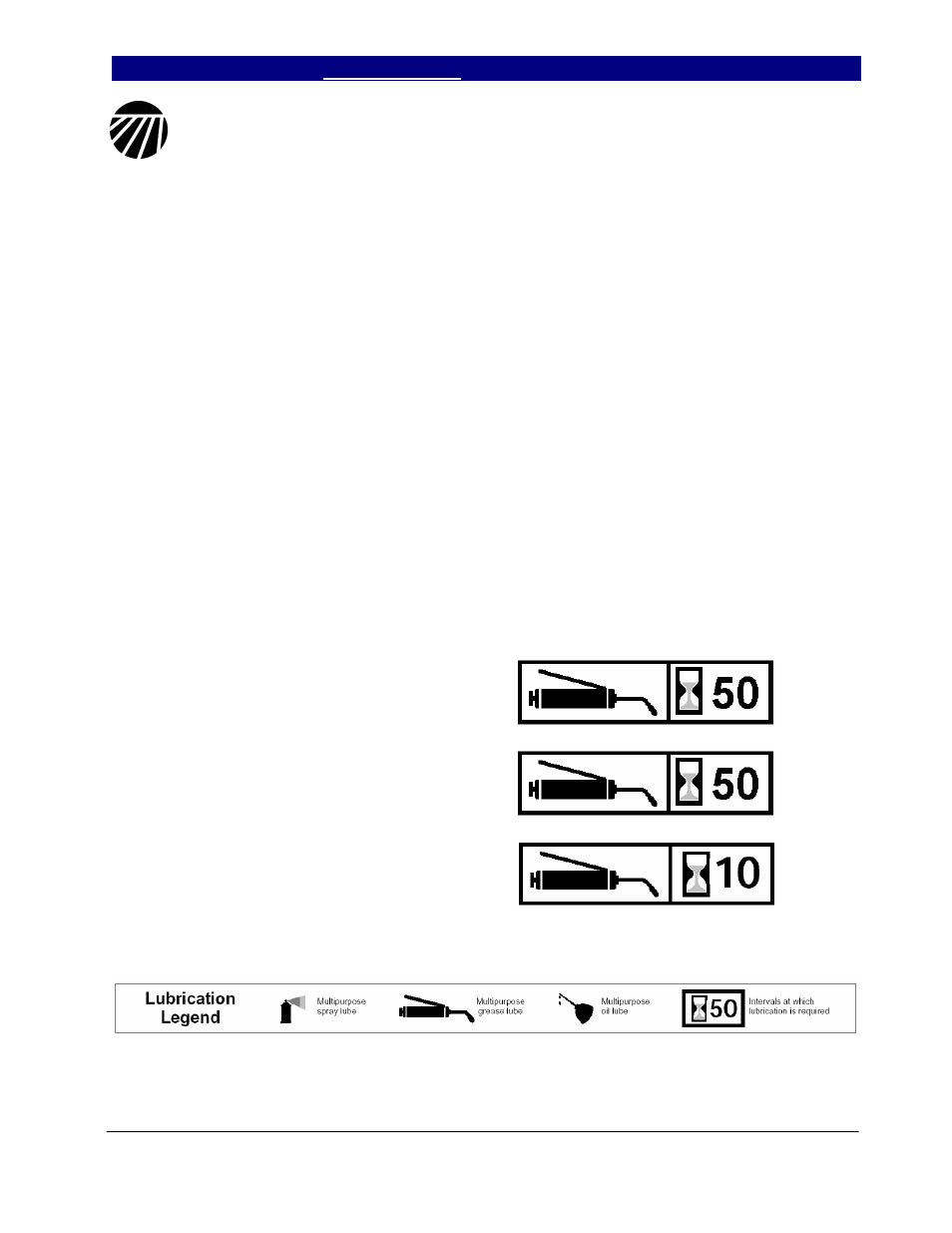

Reel Bearings

Grease every 50 hours (sparingly).

Wheel Bearings

Grease every 50 hours (sparingly) and

check for endplay.

Caster Wheels Pivots

Grease every 10 hours.

7.

If machine is stored outdoors over the winter

months it is a good idea to retract the

cylinders to protect the cylinder rods. This

will extend the life of the cylinder seals and

reduce internal and external leaks.

By following and maintaining a routine service and

lubrication program, your tillage attachment will

give you many years of service.

For more information on operating, adjusting

or maintaining your Great Plains Verti-Till

Attachment contact your local Great Plains

dealer or call

Great Plains Mfg. at (800) 255-9215