Indexing preparation – Great Plains YP625PD Material Rate User Manual

Page 27

Great Plains Manufacturing, Inc.

Sprocket Indexing (Stagger)

25

09/29/2011

401-754B

Indexing Preparation

Tools required:

1.

Find (in page 28-29) the sprocket indexing chart for

your row spacing, cell count and desired seed

population. Note the “Initial Rear Tooth Number”

value in the second column.

2.

Raise the planter.

Chain geometry changes slightly when lowered. The

indexing charts account for this change, and assume

the planter is raised. Also, raising the planter frees

the ground drive wheel, allowing you to turn the

wheel, or turn the drive shaft with a hand tool.

Crushing Hazard:

Install transport locks. Do not rely on hydraulics to hold the

planter at raised. This adjustment takes some time.

3.

Clean out meters. Leave seed discs out.

See Operator Manual for procedure.

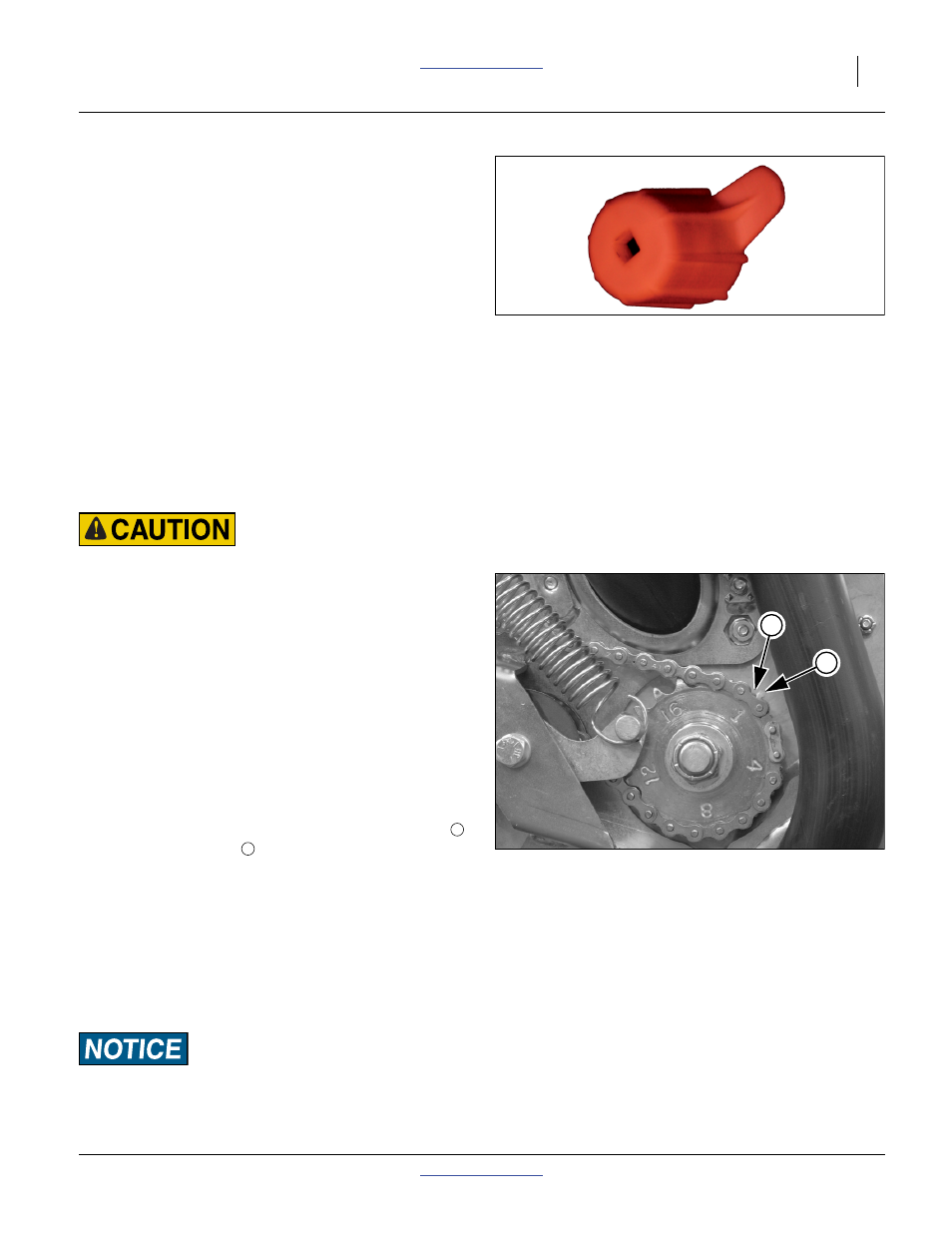

Refer to Figure 11 (which depicts tooth 1 slightly ahead of the

index rib at 2:00)

4.

Use drive shaft or ground drive wheel to set front row

unit to index 1.

Observe the meter drive sprocket at a front (short

mount) row unit on each wing. Use the ground drive

wheel, or a wrench (from the rear of the shaft, to

rotate the shaft forward - wrench up and forward).

Stop rotation when the tip of the tooth stamped “1”

is aligned with a rib

cast into the meter housing. In

general, the rib at the 2:00 position is the easiest to

use, as it is visible from the side and from behind the

meter.

5.

Check front sprocket synchronization.

Inspect all meter drive sprockets on front row units.

Check that all springs are taut, and no chains have

slack. All sprockets should be at “1”. If not, use

step 6 through step 10 to set them to 1.

Equipment Damage Risk:

Do not apply significant force to meter disk, or drive hub may

be damaged.

• 23mm (

7

⁄

8

in) open end wrench

• 10mm (

3

⁄

8

in) socket wrench, or

any socket wrench with 9.5mm square drive

• 812-391C timing tool (located on a hopper mount)

Null4:

Null4:

Null4:

Null4:

Null4:

Note: Sprocket indexing may be performed with seed

present and discs installed, but if so, you must

perform step 9 (chain taut check) by rotating the

drive shaft forward to remove slack. Reverse meter

rotation, with seed present, is not recommended.

Figure 10

812-391C Timing Tool

31445

Null4:

Null4:

Null4:

Null4:

Null4:

Note: In the future, finding front sprockets out of sync

suggests idler/spring problems, and/or worn chain.

Row drive systems must be in reliable working

order for effective sprocket indexing.

Figure 11

Sprocket Indexing Reference

29630

1

2

1

2