Great Plains YP625PD Material Rate User Manual

Page 26

401-754B

09/29/2011

24

YP625PD/TD, YP925TD

Great Plains Manufacturing, Inc.

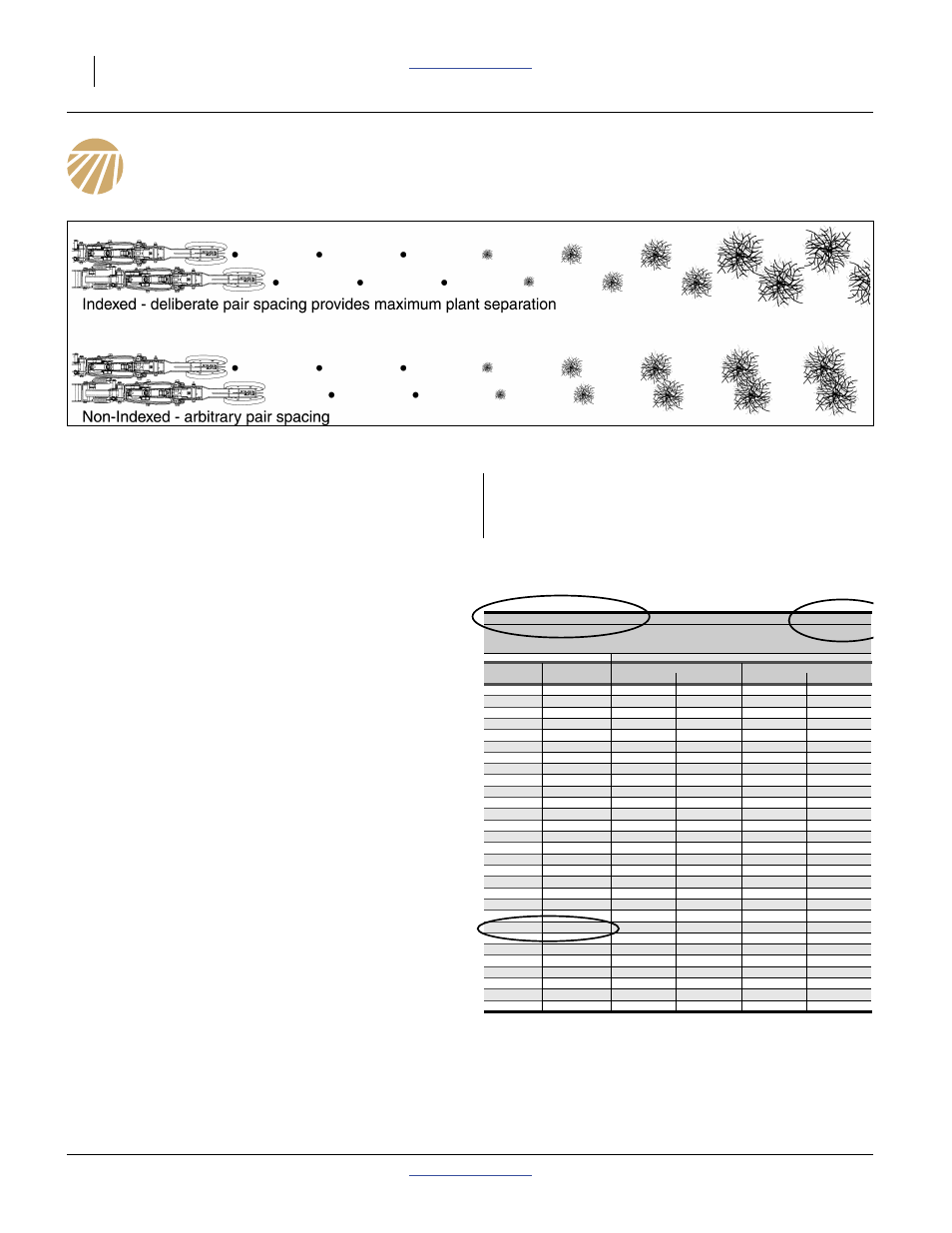

Sprocket Indexing (Stagger)

Null4:

Null4:

If you are planting:

• with a seed disc having 24 cells or less,

• twin- or tri-row crops,

• at seed populations below:

77 000 seeds/ha (Twin Row), or

116 000 seeds/ha (Triple Row)

you can synchronize the front and rear meters in a twin-

or tri-row so that you achieve the maximum seed-to-seed

spacing between the units of the set.

If the initial indexing does not provide equal spacing, See

“Indexing Fine Adjustment” on page 27.

If you are planting:

- single-row,

- or with seed discs or 25 cells or more,

- or twin/tri-row with seed spacings below 23.5cm,

this section of the manual, and the sprocket indexing

charts, do not apply to your operations.

28420

Source:

/files/manual/docs/gp/401-625b/charts/ods/reference/air_pro_meter_timing.ods

Dated:

2009-08-11T11:49

Provider

GWA

File:

/files/iso/text/31500/31823.ods

Sheet:

AB_110TW

Rendered:

2010-12-16T09:00

By: RJN

Export As:

/files/iso/text/31500/31823A.pdf

Import As:

/files/iso/text/31500/31823A.eps

110cm Twin Row

Set front meter to tooth “1”.

Page 1 of 2

Set rear meter to indicated Initial tooth number.

Advance or Retard to adjust - see instructions in Seed Rate Manual.

These Columns are for Fine Adjustment Only

Population

Initial Rear

20% Rear Seed Drop Adjust

40% Rear Seed Drop Adjust

Seeds/ha

Tooth Number

Retard

Advance

Retard

Advance

29100

7

3

4

6

16

29960

19

10

16

13

16

30810

19

10

16

13

16

31670

3

7

19

10

16

32520

4

6

19

9

12

33380

4

1

15

17

12

34240

18

11

15

14

12

35090

8

2

15

5

8

35950

8

5

11

5

8

36800

14

15

11

18

8

37660

14

15

11

18

4

38510

12

9

7

1

4

39370

10

19

7

3

4

40230

10

19

7

3

4

41080

16

13

3

10

19

41940

6

13

3

10

19

42790

6

4

3

7

19

43650

1

17

18

14

15

44510

2

17

18

14

15

45360

2

8

18

11

15

46220

5

5

18

18

11

47070

5

2

14

18

11

47930

17

12

14

15

11

48790

9

1

14

3

7

49640

9

6

10

3

7

50500

13

16

10

19

7

51350

13

16

10

19

3

52210

13

10

6

7

3

53060

9

10

6

4

3

31823A

Air-Pro

®

Meter Stagger Timing Chart

Thumbnail view. Actual charts begin on page 28.

Due to limitations on the number of sprocket teeth and

wheel cell count, it may not be possible to obtain perfect

stagger. Charts and fine adjustment provide the optimal

available stagger.