Opener down pressure, Disk scraper adjustment leaf spring adjustment, Disk scraper adjustment – Great Plains NTA2000 Operator Manual User Manual

Page 30: Leaf spring adjustment

28

NTA 2000 148-561M

2/2/2006

Great Plains Mfg., Inc.

Opener Down Pressure

Refer to Figure 33

To adjust down pressure on individual openers that run in

tire tracks, change opener-spring length.

1.

To increase down pressure, loosen the jam nut at the

lower end of opener spring, then turn flange nut. Each

additional 6 mm (1/4”) of spring compression adds

about 6 kg (13 lbs) of pressure. After adjusting flange

nut, tighten jam nut.

IMPORTANT: Do not compress spring more than 25

mm (1 inch). Compressing spring more than 25 mm (1

inch) could cause opener damage and void the warranty.

Disk Scraper Adjustment

Refer to Figure 34

To keep opener disks turning freely, dirt scrapers are

mounted between disks to clean as the disks rotate. As

field conditions vary, you may need to adjust the scrapers.

2.

To adjust, loosen 3/8” bolt and raise or lower scraper

as needed.

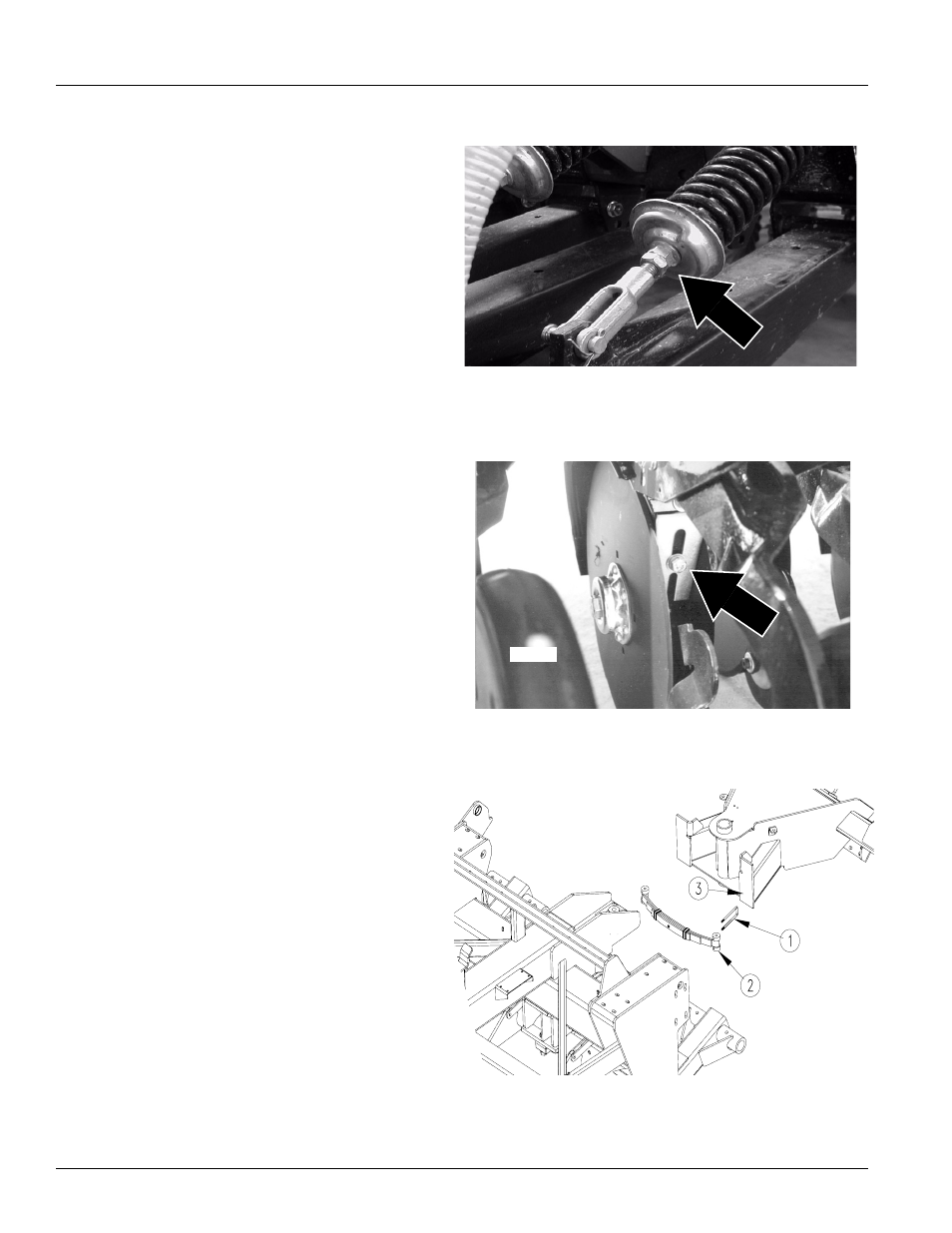

Leaf Spring Adjustment

Refer to Figure 35

A leaf spring is located just ahead of the vertical pivot. The

spring is designed to provide just enough force to keep the

opener frame square and stable for turning at field ends

and to add stability for drilling in rough field conditions.

Proper leaf-spring adjustment is important for smooth

implement operation.

1.

To adjust properly, square the opener frame to the

coulter frame and adjust 3/8” U-bolts (1) on each side

until leaf-spring rollers (2) just make contact with roller

pads (3) on opener frame. When the U-bolts are ad-

justed properly the opener frame should be square

with the coulter frame when the drill is raised.

Figure 33

Individual Spring Adjustment

Figure 34

Disk Scraper

Figure 35

Leaf Spring Adjustment

16634

19888

19895