Coulter command assembly adjustments – Great Plains CP1000 Assembly Instructions User Manual

Page 11

9

Section 1 Assembly Instructions & Set-Up

9/21/05

CPH and CP1000 Coulter Command System 148-258M-B

Great Plains Mfg., Inc.

Control Box

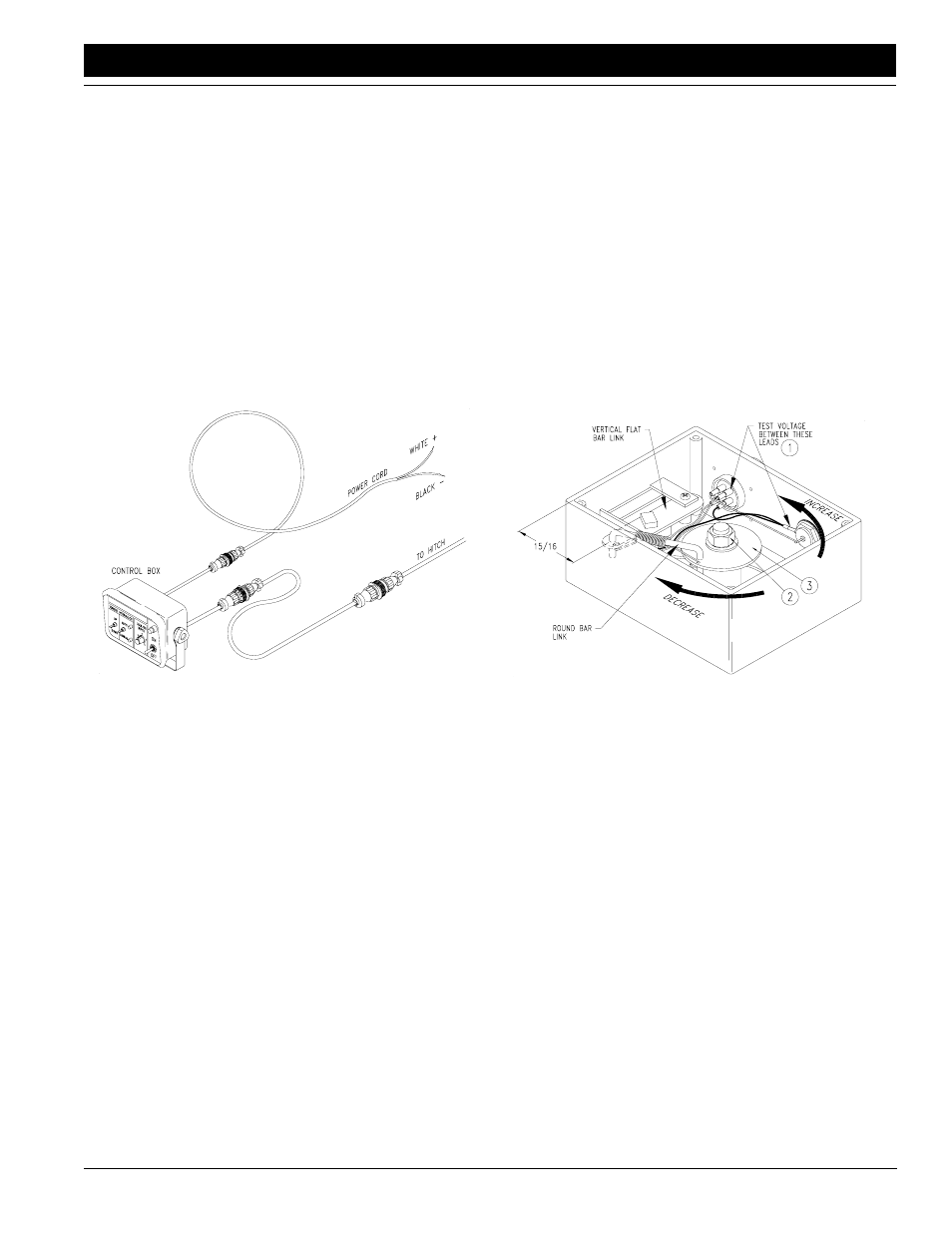

Refer to Figure 6

1.

Mount the control box at a convenient location in the

tractor cab. Connect the 12’ extension cable to the

9-pin connector on the back of the control box and

route the cable back toward the tractor drawbar area

making sure it will not get kinked or pinched.

2.

Connect the power cord to a good uninterrupted 12

volt power source on the tractor. Connecting directly

to the battery is recommended. Plug the cord into

the lead with the 2-Pin connector on the back of the

control box. The polarity of the power supply is very

important to prevent circuit damage. The white wire

of the power cord must be connected to the "+" pos-

itive battery terminal and the black wire to the "-"

negative battery terminal.

Coulter Command

Assembly Adjustments

Refer to Figure 7

Coulter command depth sensing wheel assemblies

which are pre-assembled at the factory are pre-adjusted

and should not require further adjustment. If the sensor

box at the depth sensing wheel has been field installed,

or if its linkage gets out of adjustment, it must be adjust-

ed using one of the following two procedures:

1.

The best and most accurate means of adjusting the

linkage inside the sensor box makes use of a volt-

meter which reads 0-12 volts DC. The Control Box in

the tractor must be properly connected to a power

source and the POWER switch must be ON. The

TONGUE HYDRAULICS switch should be in the

MANUAL mode. The wiring harness must be con-

nected to the control box and the sensor box. The

depth sensing wheel should be off the ground with

the arm rotated down as far as its spring-loaded

down-pressure link will allow. Remove the cover

from the sensor box and inspect the internal linkage

for proper assembly.

Figure 6

Coulter Command Control Box

12575

With the depth sensing wheel in the max down posi-

tion, the voltage potential between the lead contain-

ing the WHITE WIRE and the ground lead (BLACK

WIRE) in the gauge wheel sensor box (#1) should

be 5 volts DC plus or minus 1/4 volt. To adjust the

gauge wheel sensor box linkage, loosen the 3/8"

hex flange nut (#2) on the sensor spindle and rotate

the circular disk (#3) until the voltage potential be-

tween the lead containing the WHITE WIRE and the

ground lead (BLACK WIRE) (#1) is 5 volts DC plus

or minus 1/4 volt. Rotating the circular disk counter-

clockwise increases voltage potential, and rotating

the circular disk clockwise decreases the voltage

potential. Once the correct voltage potential is

achieved, tighten the 3/8" nut. Be careful not to ro-

tate the circular disk as you tighten the nut. Replace

the sensor box cover.

2.

The second means of adjusting the linkage inside

the sensor box involves measuring from the inside

edge of the box to the left pivot of the formed round-

bar link. The depth sensing wheel should be off the

ground and rotated down as far as its spring-loaded

down-pressure link will allow. Remove the cover

from the sensor box and inspect the internal linkage

for proper assembly.

With the depth sensing wheel in the max down posi-

tion, the pivot between the vertical flat-bar link and

the formed round-bar link should be 15/16" from the

front inside edge of the sensor box.

With the sensor box linkage properly assembled,

loosen the 3/8" hex flange nut on the sensor spindle

and rotate the circular disk until the pivot between the

vertical flat-bar link and the formed round-bar link is

15/16" + or - 1/16" from the front inside edge of the

box. Be careful not to rotate the circular disk as you

retighten the nut. Replace the sensor box cover.

3.

Some models of the sensor box have a mark on the

vertical flat-bar link which should line up with a mark

on the link’s slotted mount plate at the correct preset

voltage. With the depth sensing wheel in the max

down position, the marks should line up at a voltage

of 5 volts DC + or - 1/4 volt. Aligning the marks is more

Figure 7

Sensor Box Adjustments

12619