Re-install contact drive arms, Install new pivot shaft – Great Plains NTA3007HD Operator Manual User Manual

Page 8

8

Great Plains Manufacturing, Inc.

Contact Drive Update

166-367M

02/21/2012

Re-install Contact Drive Arms

Start with the right side of the implement. Two workers

may be needed due to parts that are held in alignment

for shaft insertion.

Install New Pivot Shaft

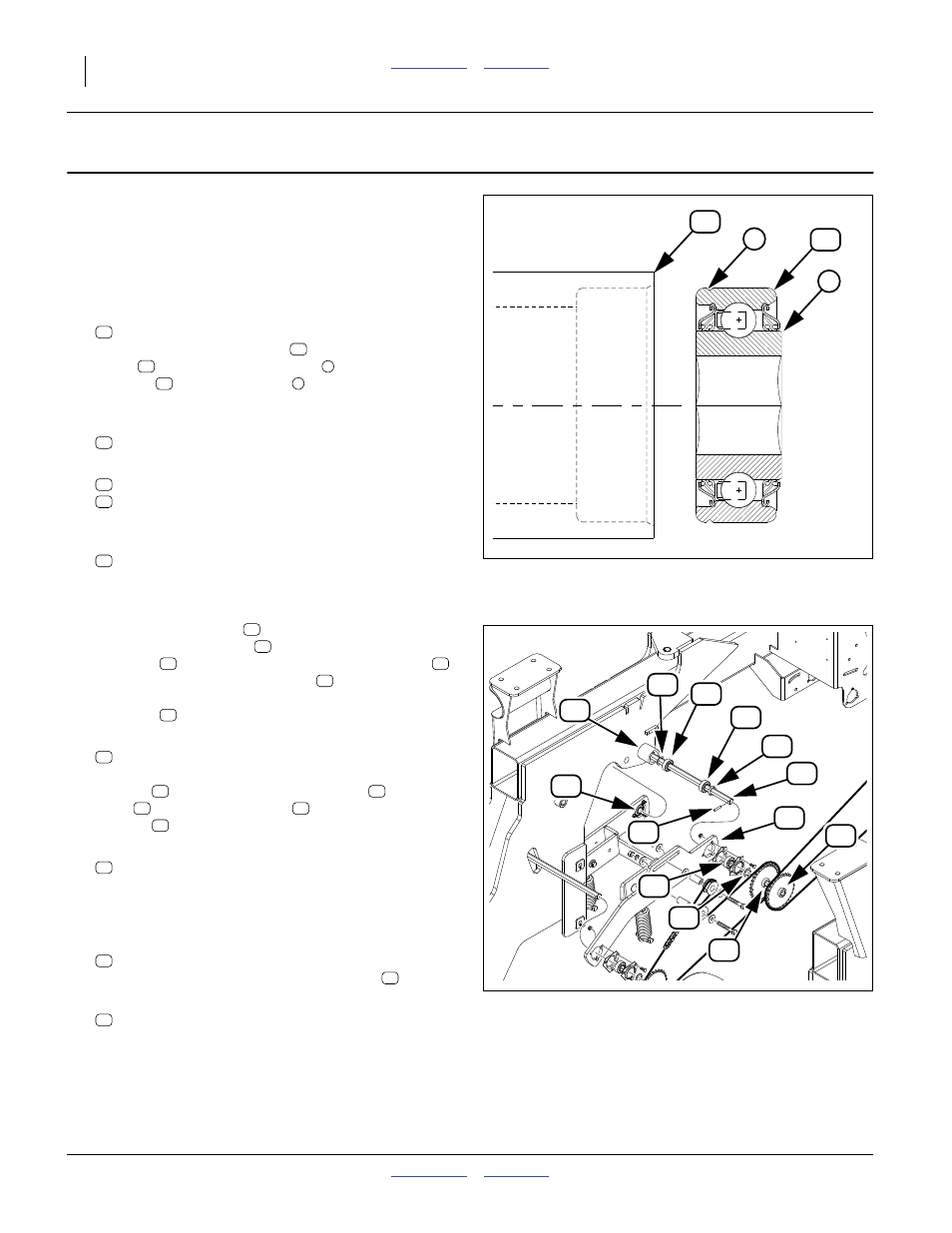

Refer to Figure 14

46. Select two new:

188-006V BEARING .880 HEX BORE 205DD

Insert and seat one bearing

tubes

. The orientation groove

is to the inside of

the tube

. The raised face

of the inner race is to

the outside of the tube.

47. Select one new:

266-296D CONTACT WHEEL PIVOT SHAFT

48. Select the saved:

166-201H CONTACT DRIVE WELDMENT RIGHT

166-205H CONTACT DRIVE WELDMENT LEFT

depending on the side being worked on.

49. Select one each new:

402-266D 7/8 HEX SHAFT SPACER TB X 9

Note: Make sure that the arms are above the new down

stops (not shown) before the next step.

50. Hold the spacer tube

against the inside face of

the inside arm bearing

. Bring the existing arm

bearings

into alignment with the new bearings

.

From the inside, insert the shaft

through the exist-

ing bearing, spacer tube and both pivot tube

bearings

51. Select one new:

804-061C WASHER MACH 1.50 X 1.00 X 1

Slide this washer between the outside pivot tube

bearing

and the outside arm bearing

, Slide the

shaft

through the washer

and the outside arm

bearing

52. Select the number of saved:

804-061C WASHER MACH 1.50 X 1.00 X 18GA

per the “Output Shaft” table (page 4) for the side of

the implement being worked on. Place these on the

inside end of the shaft.

53. Select two saved 30T sprockets:

808-319C SPKT 50C30 X 7/8 HEX BORE

Place them on the inside end of the shaft

54. Select two:

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

Drive the pins through the ends of the shaft.

55. Repeat step 46 through step 54 for the left side.

Figure 13

Bearing Orientation

32104

7

8

Figure 14

Pivot Tube and Bearings

29379

15