Cut clearances, Elongate input shaft slot, Notch spring brackets – Great Plains NTA3007HD Operator Manual User Manual

Page 5

Cut Clearances

Great Plains Manufacturing, Inc.

5

02/21/2012

166-367M

Cut Clearances

Elongate Input Shaft Slot

The curved slots (4 places) for the contact drive input

shaft need to be elongated by 21.0 mm (0.83 in).

Refer to Figure 6 and Figure 21 on page 12

25. Make two copies of page 12 at 1:1 (100%) size (or

print at 100% size from the PDF of this manual), for

use as marking templates. A ruler image is included

on the page to verify that the copy is 1:1 scale.

26. Mark the elongation boundary (the dashed line) on

the tongue mount plates.

27. Use a torch, or similar tool capable of cutting thick

steel, to elongate the four curved slots

. Check the

final edge against the template.

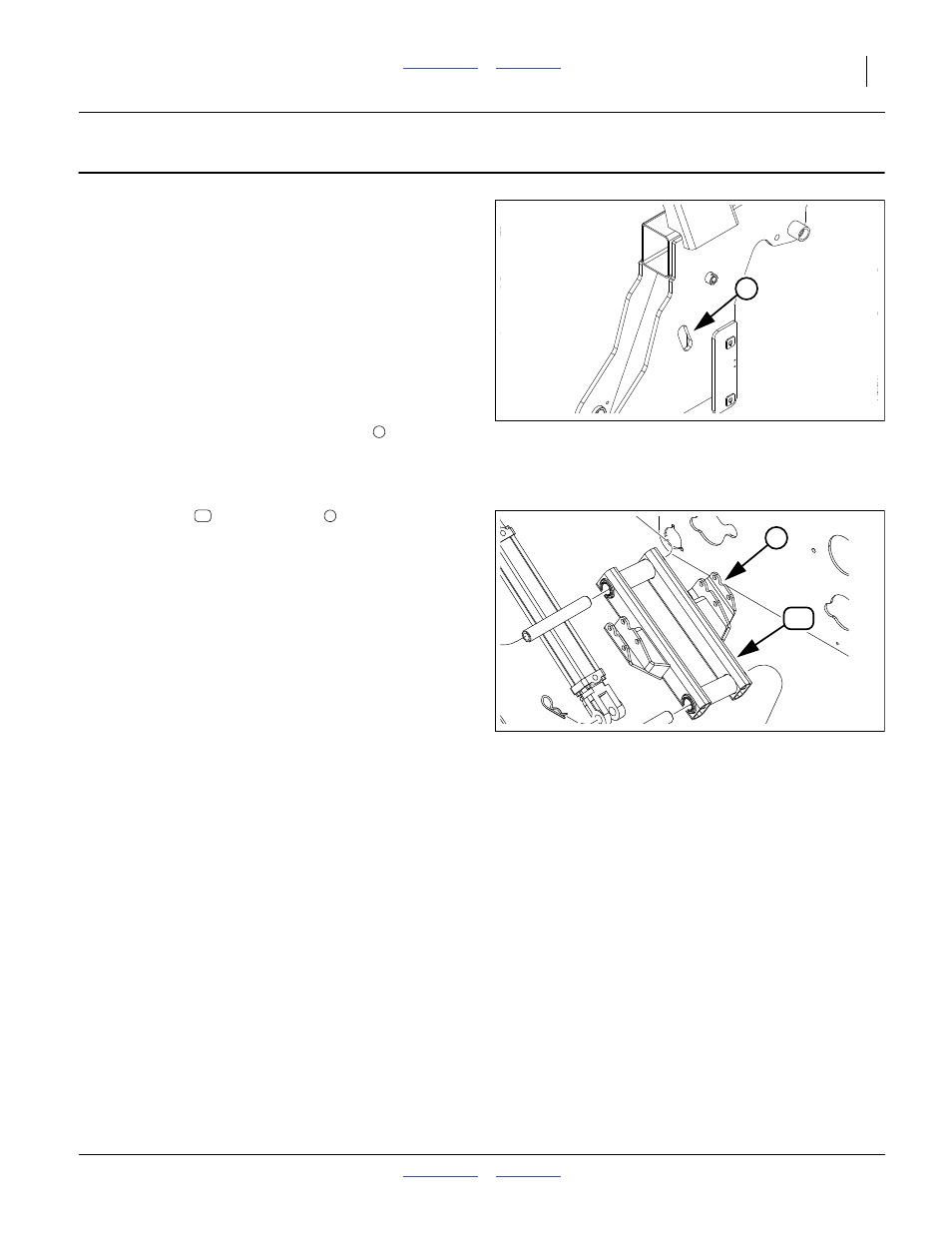

Notch Spring Brackets

The parallel arm

spring brackets

(where the bottom

of the hold-down springs attach) need to have a notch

cut in them (8 places) to allow spring clearance at the

limits of the arm movement now allowed by the longer

curved slots.

Refer to Figure 7 and Figure 20 on page 11

28. Make four copies of page 11 at 1:1 (100%) size (or

print at 100% size from the PDF of this manual), for

use as marking templates. A ruler image is included

on the page to verify that the copy is 1:1 scale.

29. Mark the notch boundary (the dashed line) on the

tongue mount plates.

30. Protect neighboring machine parts from being over-

heated.

31. Use a torch, or similar tool capable of cutting thick

steel, to cut the notches. Check the final edges

against the template.

Figure 6

Input Shaft Slot

29379

3

Figure 7

Spring Brackets with Notches

29434

4