Servicing and maintenance, 1 servicing, 2 cleaning – Great Plains SLD600 Operator Manual User Manual

Page 29: 3 disc hub maintenance

29

Simba SLD

602-227M-ENG

2013-02-05

5. Servicing and

Maintenance

Follow the safety instructions for

servicing and maintenance.

5.1 Servicing

Your machine has been designed and

constructed for maximum performance,

operational efficiency and operator

friendliness under a wide variety of operating

conditions.

Prior to delivery, your machine has been

checked at the factory and by your authorised

dealer to ensure that you receive a machine

in optimum condition.

To ensure trouble-free operation,

it is important that servicing and

maintenance work is performed at

the recommended intervals.

5.2 Cleaning

In order to ensure that the machine is

always in operating condition and to achieve

optimum performance, perform the cleaning

and servicing work at regular intervals.

Avoid cleaning the roll / disc bearings with

a high-pressure hose or a direct water jet.

The housing, screwed connections and ball

bearings are not watertight.

5. Servicing and Maintenance

Regularly examine hub caps,

seals and pivot bolts and all

tracking bolts for tightness and

effectiveness twice weekly or

every 50 working hours (whichever

is more frequent).

5.3 Disc Hub

Maintenance

Grease every disc hub until grease shows

from the seals according to the lubricating

intervals outlined on page 35.

Check disc hubs regularly for tightness.

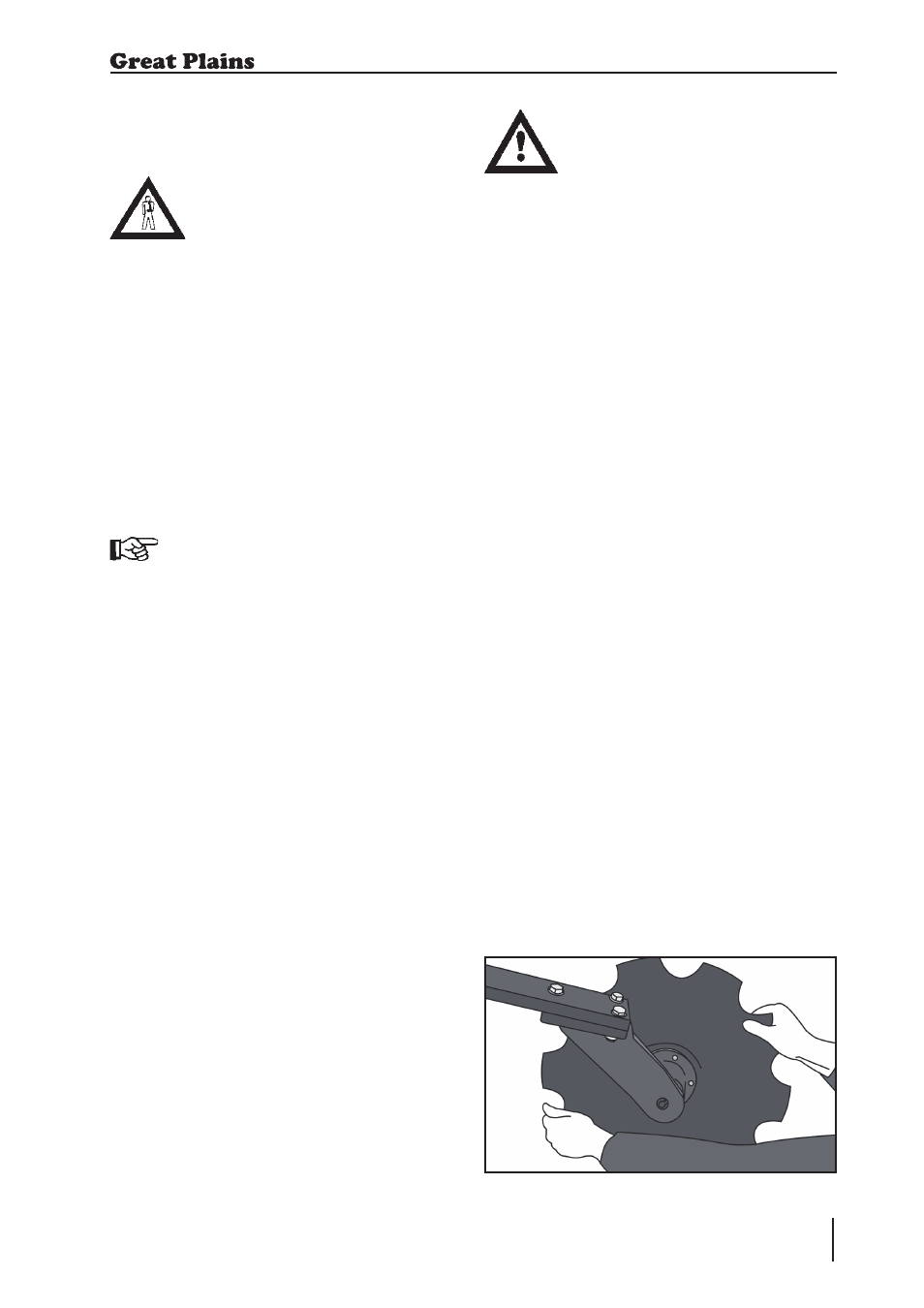

Fig. 5.01: Checking Disc Bearing Adjustment

1

Ensure that the bearing seal is in the

correct orientation when replacing /

assembling components.

2

Ensure that the stub axle is free from

dirt and the nut and outer bearing can

easily slide on it.

3

Tighten the crown nut with a hand

spanner (a torque wrench is not

required) while turning the hub

clockwise until the bearing drags

slightly (you feel the hub turning

heavily). Some resistance will be due

to friction from the seal.

4

Turn back the crown nut to the next

locking position. Even if the tightening

of the nut has reached an exact fixing

position, turn it back.

5

Insert the retaining pin.

6

Try to shake/rock the outer edge of the

hub/spindle: play of 0.1 / 0.2mm will

not reduce the bearings’ life and, in

addition, prevents overheating. If the

adjustment is correct the hub should

turn freely with the only friction being

from the seal.

5.3.1 Tightening Disc Hubs

Е

Е

Е

Е