System discharge, Normal discharge – Great Plains NH3 Safety User Manual

Page 43

Great Plains Manufacturing, Inc.

Ammonia Maintenance Safety

39

2013-07-15

407-551M

System Discharge

These steps are for clearing an implement for service or

for storage near untrained persons. These instructions

presume that you have followed the steps at:

“Stopping Application” on page 29,

and the nurse tank is unhitched, per:

“Final Nurse Tank Unhitch” on page 31.

For a breakaway event, follow the instructions on

page 33 up through breakaway re-connection. Then

perform a normal shutdown (other than nurse tank

steps), per page 29.

The challenges in system discharge are:

• NH

3

liquid can remain in the system after the

recommended stopping procedures.

• NH

3

liquid self-cools as it evaporates, slowing

evaporation. It can take a long time for all of it to turn to

vapor, particularly in cooler weather.

• Once there is only vapor in the system, there is usually

little gas movement to drive the rest of it out.

• The applicator tubing loops are usually the last to

clear, and may not fully clear. See sidebar.

Even if no ammonium hydroxide forms, the NH

3

vapor in

the system dilutes slowly with air. Harmless trace

amounts, noticed as occasional odor, may remain

indefinitely.

Normal Discharge

At the completion of stopping application and nurse tank

unhitching, all line valves are closed and all bleed valves

are open, and have been that way for at least an hour.

Transport may also have occurred, which aids clearing.

1.

Verify that all line valves are closed, and all bleed

valves open. If this is not the case, there is risk of

trapped ammonia. See “Clearing a Line Trap” on

page 37.

2.

Carefully walk down-wind of the implement. Check

for ammonia odor. If pungent, there is at least some

pure NH

3

vapor in the system, and possibly some

liquid. Give the implement some time to vent.

If there is no, or only mild odor, check the applicator

loops for visible fluid. If only a few hours have

elapsed since application ended, this liquid is pure

NH

3

. Stay away until it has vaporized.

3.

From up-wind, check all the fittings and lines. If any

are cold (more than a few degrees below ambient

temperature), liquid evaporation is still in progress or

has only recently completed. Give the implement

more time to vent.

Steps continue on next page...

Suffocation, Blinding, Burning, Freezing, Disabling and

Disfigurement Hazards:

Do not perform maintenance with anhydrous ammonia in the

system. Fully discharge the system of NH

3

liquid and vapor

before working on the implement.

The applicator tubes are open to the atmosphere at the

tines or knives. When they don’t clear immediately, they

are likely to absorb atmospheric moisture, forming

ammonium hydroxide (NH

4

OH) in the tubes. This liquid

is highly caustic, and can persist for weeks or months,

but remains liquid at ambient temperatures, is harmless

to the tubing, and emits ammonia vapor slowly. If there

is liquid in the tubes, and it is not cold, it is likely to be an

NH

4

OH solution, and not pure NH

3

.

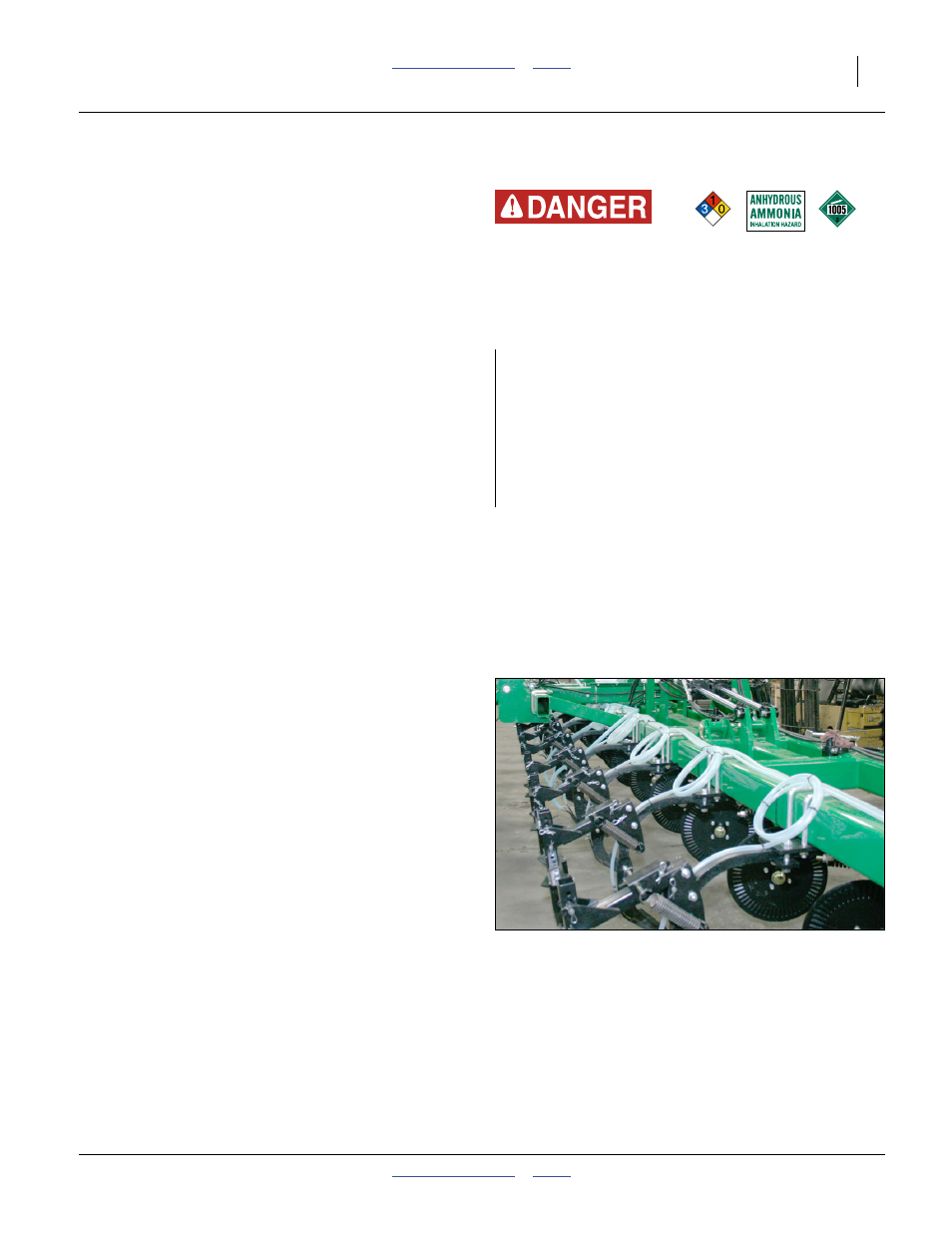

Figure 31

Applicator Loops

31617