Avoid trapped anhydrous, Avoid line traps, Clearing a line trap – Great Plains NH3 Safety User Manual

Page 41: En when completely disconnected. see “avoid

Great Plains Manufacturing, Inc.

Ammonia Maintenance Safety

37

2013-07-15

407-551M

Avoid Trapped Anhydrous

Before servicing anhydrous equipment, or storing it near

untrained individuals, be absolutely certain that there is

no liquid NH

3

trapped in the system, and no NH

3

vapor

present (or only trace amounts).

Follow bleeding and discharge instructions carefully.

Beware of places in the systems where NH

3

can be

trapped.

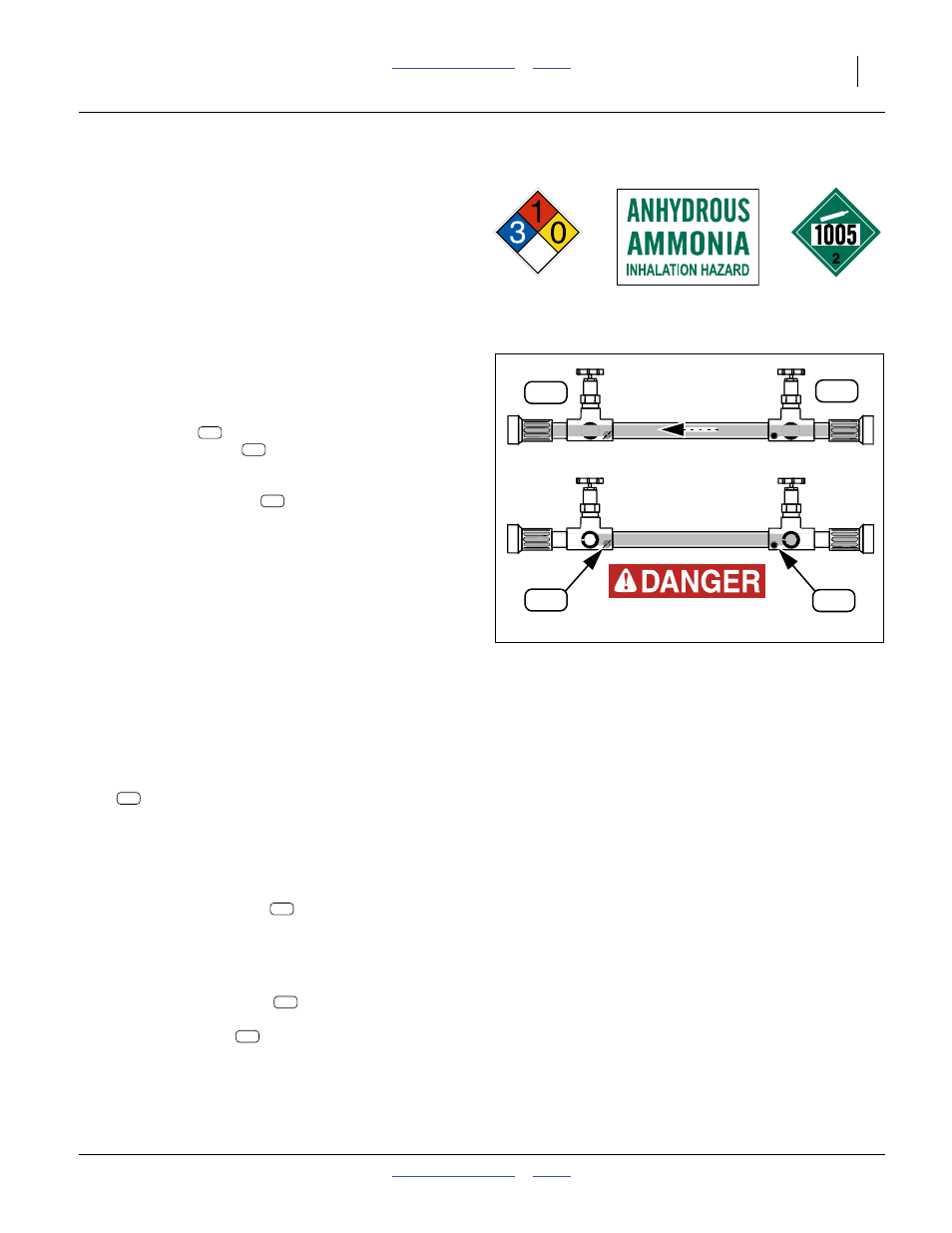

Avoid Line Traps

Refer to Figure 30

Any two line valves in the system, if both closed with NH

3

present, can trap that ammonia indefinitely. Line valves

include:

tank withdrawal

(page 16),

nurse tank hose valve

(page 13),

check valves at a disconnected breakaway,

emergency shut-off valve,

control valve at rate zero

On/Off solenoid valve, and

aftermarket section valves.

In a properly designed system, segments not open to the

atmosphere are protected by hydrostatic relief valves,

but the operation of such valves only releases a small

portion of the trapped ammonia.

Normal shut-down instructions, after closing the tank

withdrawal valve, are intended to bleed most of the

system NH

3

into the soil. However, there can still be

substantial vapor in the system after that. And if shut-

down procedures were not followed (or the state of the

equipment is unknown at time of servicing), you need to

assume that a closed valve represents a risk of trapped

NH

3

.

The illustration at right depicts a nurse tank

hose

(page 12) in use, and shut-off while still full of

liquid NH

3

. If this hose is removed to an enclosed space,

then opened, it represents an extreme hazard. Vapor

concentrations could rise to well above IDLH levels in

moments.

This example system line segment is equipped with relief

orifice-equipped ball valves

(page 13), but that only

bleeds the downstream side of a valve ball, the outlet

valve in this example. See page 38 for information about

ball traps.

The downstream side of this system line segment is

equipped with a bleed valve

(page 13). The

upstream side of the inlet valve is equipped with a

hydrostatic relief valve

(page 14).

If this line segment warms, pressure can rise high

enough to cause periodic releases at the relief valve.

This protects the segment from rupture, but does not

clear the line.

Clearing a Line Trap

To clear a line segment with possible trapped NH

3

:

▲ Move the equipment outdoors.

▲ If calm, wait for wind.

▲ Stand up-wind of the bleed valve.

▲ Point the bleed valve orifice down-wind and away from all

personnel.

▲ If it’s a hose bleed valve, make sure you can set the hose

down with the valve still pointing in a safe direction.

▲ Open the valve very slowly. Once any discharge is

observed, (set any hose down) depart up-wind.

▲ Remain up-wind until the discharge completes.

Figure 29

NH

3

Trapped in Line

31616

Valves Open in Use

Valves Closed with

NH

3

Present

A61

A62

A61

A63

A66

A61

A30

A59

A61

A62

A63