Drill holes and assemble, Mark holes, Ud b f – Great Plains 1007NT-1906 Assembly Instructions User Manual

Page 5

Drill Holes and Assemble

Great Plains Manufacturing, Inc.

5

08/21/2009

151-169M

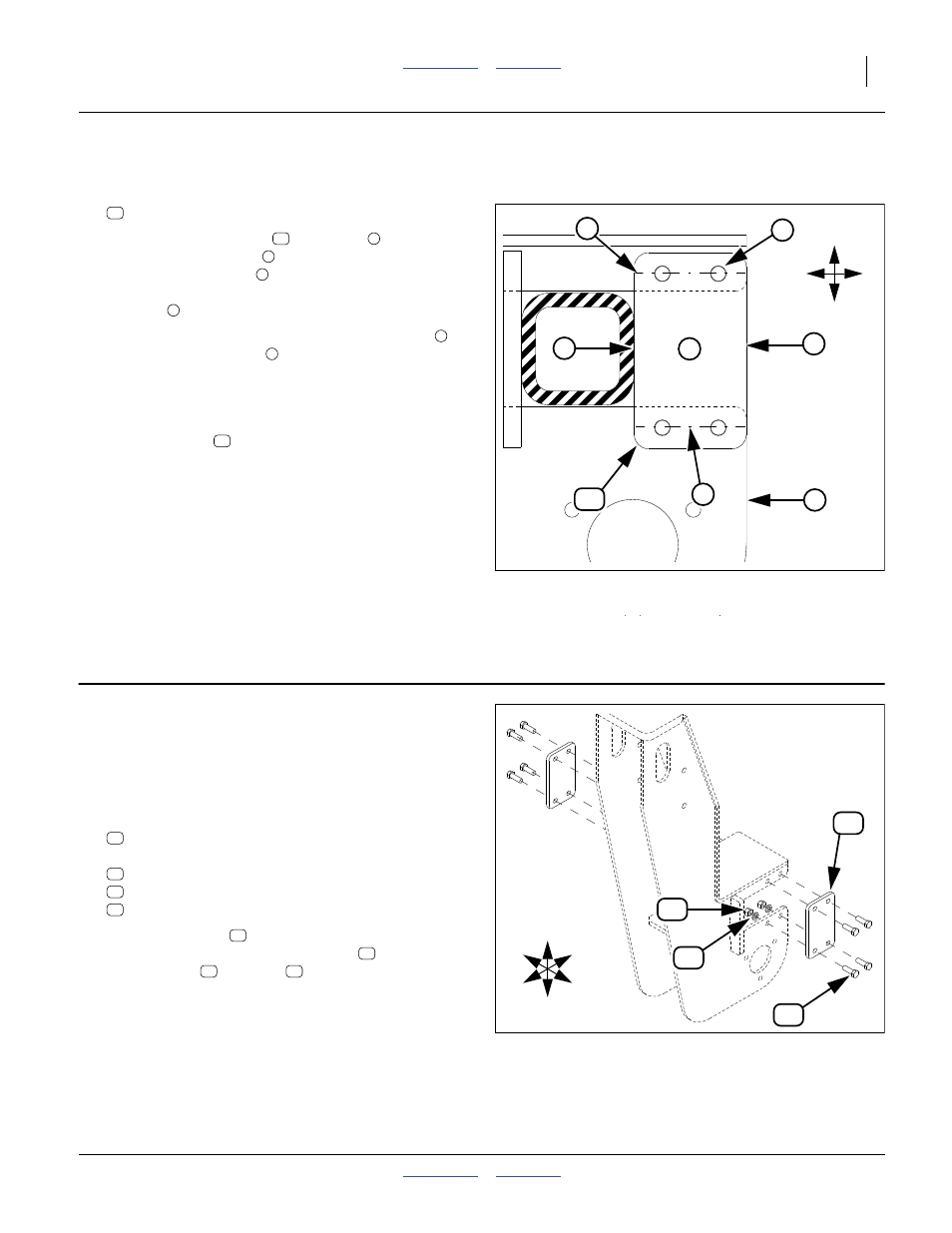

Mark Holes

Refer to Figure 6

15. Select one new:

151-359D REAR CASTER BRACE PLATE

16. Position the brace plate

front edge of the plate

weldment side plates

. If it is not possible to align

the front edges, push the brace plate back against

the tube

17. Adjust the vertical position so that all four holes

are on the center-lines

18. If the plate cannot be positioned high enough for the

top holes to reach center-line, it may be necessary to

grind off some of the weld fillet there.

19. Using the plate

as a template, mark all four holes.

Use a center-punch to make a detent at each hole

center (which may not be precisely on center-lines).

20. Repeat step 13 through step 19 for the left side of

the weldment, and both sides of the left weldment.

21. If any grinding was necessary, sand and repaint the

area prior to final assembly.

Drill Holes and Assemble

Refer to Figure 7

Start with the right side of the right caster weldment.

22. Using the pilot bit, drill a small hole at each of the 4

hole locations.

23. Using the final bit, drill the final hole at each location.

24. Select one new:

151-359D REAR CASTER BRACE PLATE

and four sets new:

802-091C HHCS 1/2-13X1 1/2 GR5

804-015C WASHER LOCK SPRING 1/2 PLT

803-020C NUT HEX 1/2-13 PLT

25. Position the plate

at the outside of the weldment.

From the outside, insert all four bolts

. Secure with

lock washers

and nuts

to torque spec:

76 ft-lbs (105 N-m)

26. Repeat step 22 through step 25 for the left side of

the weldment, and both sides of the left weldment.

Figure 6

Position a Brace

29714

3

2

4

5

7

U

D

B

F

1

2

5

7

Figure 7

Brace Installation

29712

U

D

B

F

R

L