Bleeding marker hydraulics, Disk scraper adjustment seed-lok lock up, Caution – Great Plains 2420 Operator Manual User Manual

Page 26: Warning, Disk scraper adjustment, Seed-lok lock up

24

Section 3 Adjustments

2400, 2410 and 2420 Three-Point Drill 118-706M

5/15/06

Great Plains Mfg., Inc.

Bleeding Marker Hydraulics

To fold properly, the marker hydraulics must be free of air.

If the markers fold in jerky, uneven motions, follow these

steps.

!

CAUTION

You may be injured if hit by a folding or unfolding marker.

Markers may fall quickly and unexpectedly if the hydraulics fail.

Never allow anyone near the drill when folding or unfolding the

markers.

!

WARNING

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin. Check all hydraulic lines and fittings before

applying pressure. Fluid escaping from a very small hole can be

almost invisible. Use paper or cardboard, not body parts, and

wear heavy gloves to check for suspected leaks. If injured, seek

medical assistance from a doctor that is familiar with this type

of injury. Foreign fluids in the tissue must be surgically removed

within a few hours or gangrene will result.

1.

Check that tractor hydraulic reservoir is full.

2.

With both markers lowered into field position, loosen

hydraulic-hose fittings at rod and base ends of marker

cylinders. If applicable, loosen fittings on back side of

sequence valve.

3.

With tractor idling, activate tractor hydraulic valve until

oil seeps out around a loosened fitting. Tighten that fit-

ting.

4.

Reactivate tractor hydraulic valve until oil seeps out

around another loosened fitting. Tighten that fitting.

Repeat process until all loosened fittings have been

bled and tightened.

IMPORTANT: Never bleed an O-ring fitting. Instead,

bleed a nearby pipe or JIC fitting.

IMPORTANT: JIC fittings do not require high torque.

JIC and O-ring fittings do not require sealant. Always

use liquid pipe sealant when adding or replacing pipe-

thread fittings. To avoid cracking hydraulic fittings from

over tightening, do not use plastic sealant tape.

Disk Scraper Adjustment

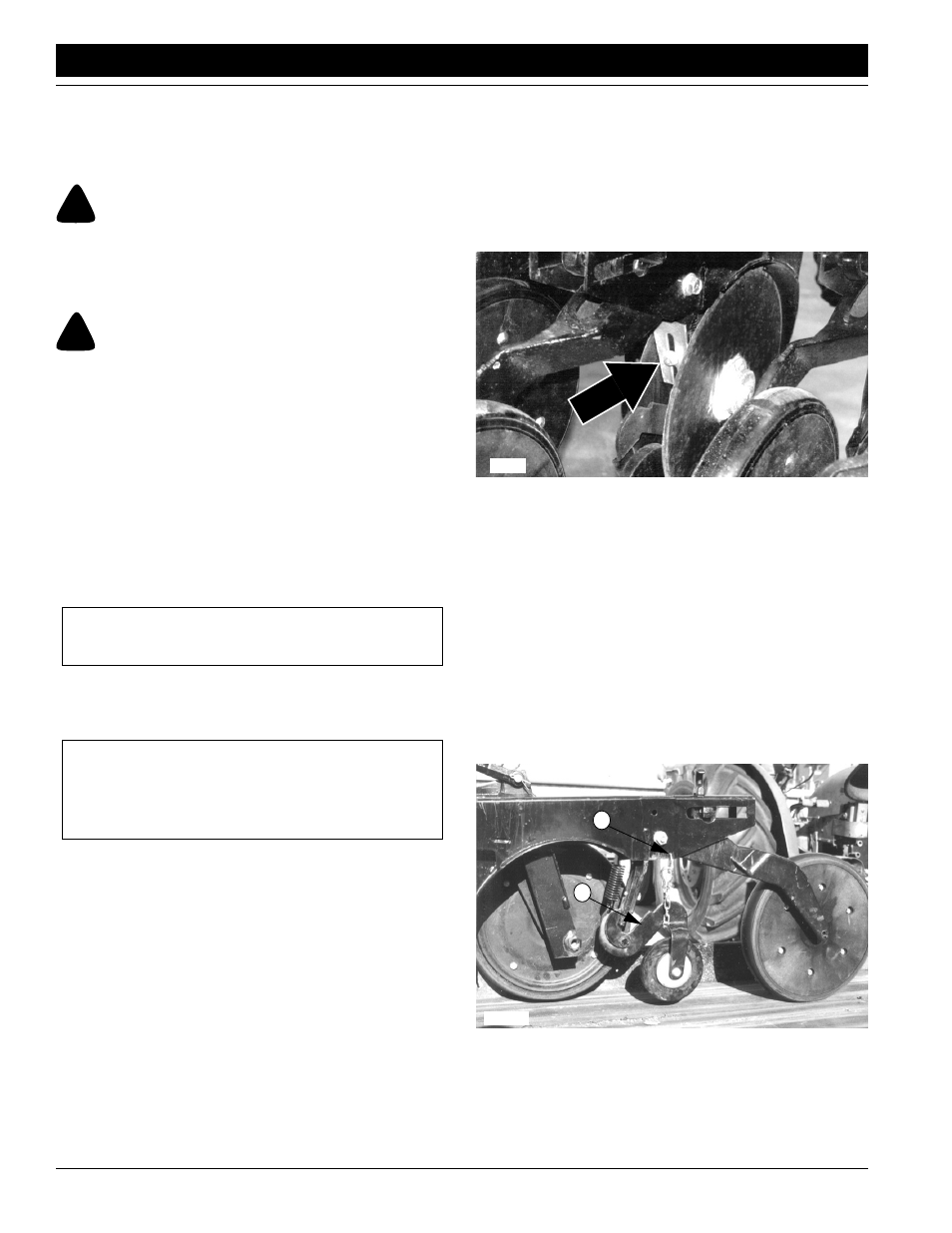

To keep the double-disk openers turning freely, dirt scrap-

ers are mounted between the disks to clean as the disks

rotate. A scraper is shown in Figure 3-17.

As field conditions vary, you may need to adjust the scrap-

ers. In damp conditions, lower the scrapers. If openers are

not turning freely, raise the scrapers. To adjust, loosen the

3/8-inch bolt and move scraper as needed.

Figure 3-17

Disk Scraper

NOTE: Optional Air-Design disk scrapers are self adjust-

ing.

Seed-Lok Lock Up

Optional Seed-Lok firming wheels provide additional

seed-to-soil contact. The wheels are spring loaded and do

not require adjusting. In some wet and sticky conditions

the wheels may accumulate soil.

To lock up firming wheels on 00 and 10 series openers,

hook one end of chain in the opener-body hole just above

the wheel arm (1). Pull firming-wheel arm (2) up as high as

possible and wrap chain around arm. Hook other end of

chain in a link. Leave no slack in chain; secure wheel arm

in its highest position.

Figure 3-18

Seed-Lok Lock Up, 00 and 10 Series Openers

16163

1

2

16856