Marker adjustments – Great Plains 2420 Operator Manual User Manual

Page 24

22

Section 3 Adjustments

2400, 2410 and 2420 Three-Point Drill 118-706M

5/15/06

Great Plains Mfg., Inc.

Marker Adjustments

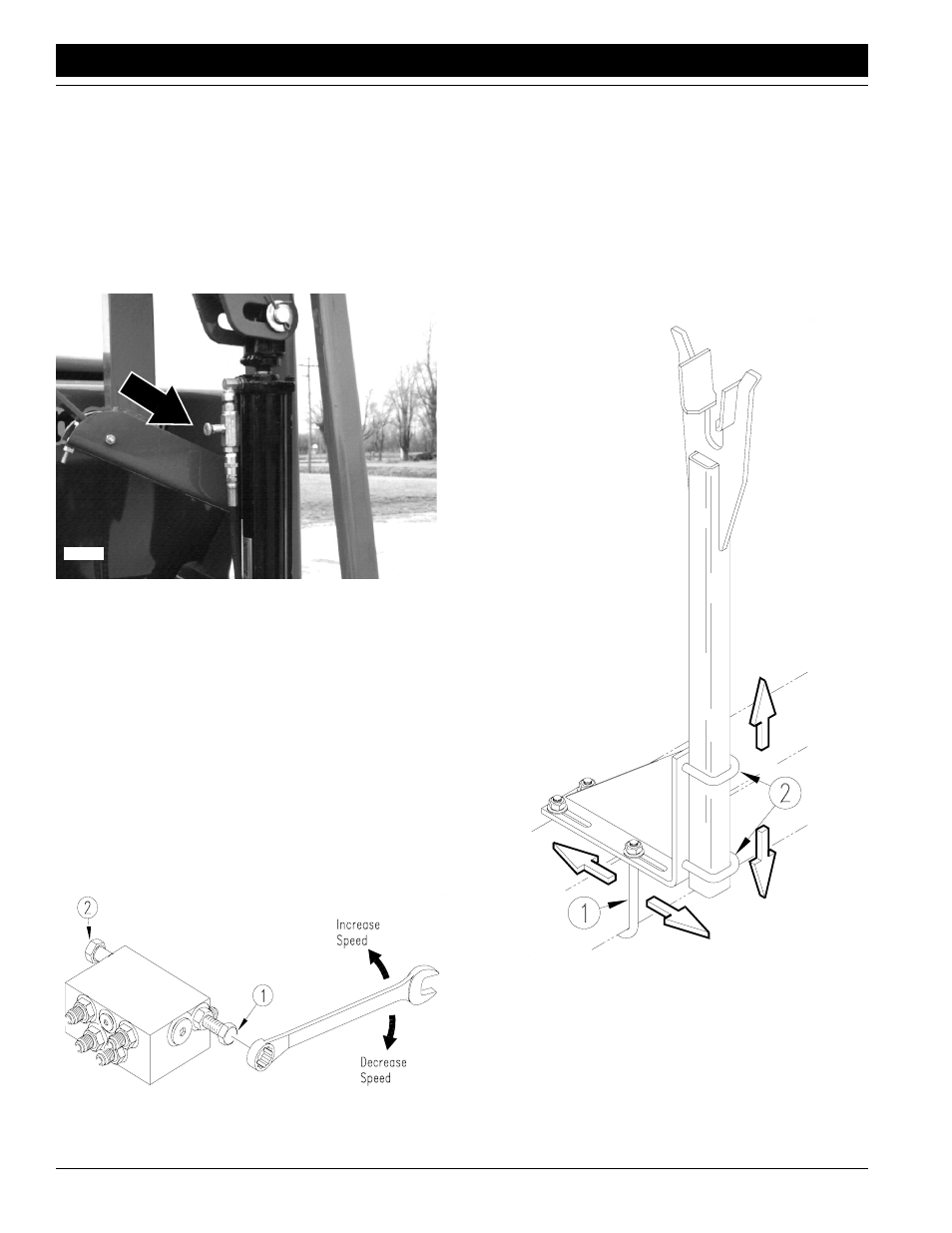

Folding Speed with Needle Valves

A needle valve controls the folding speed of markers that

are plumbed separately. The needle valve is near the rod

end of the marker cylinder. See Figure 3-12.

With tractor idling at a normal operating speed, adjust

marker folding to a safe speed. Turn adjustment knob

clockwise to reduce folding speed or counterclockwise to

increase folding speed. Excessive folding speed could

damage markers and void the warranty.

Figure 3-12

Needle Valve

Folding Speed with Sequence Valve

If markers are tied together with an optional sequence

valve, adjust folding speed with hex adjustment screws on

the sequence-valve body. See Figure 3-13. There is one

adjustment screw for raising speed (1) and one for lower-

ing speed (2). Identify adjustment screws by markings

stamped in valve body.

With tractor idling at a normal operating speed, adjust

marker folding to a safe speed.Turn adjustment screws

clockwise to decrease folding speed and counterclock-

wise to increase folding speed. Excessive folding speed

could damage markers and void the warranty.

After adjusting the folding speed, tighten jam nuts on hex

adjustment screws to hold settings.

Figure 3-13

Speed Adjustment, Sequence Valve

17620

14048

Transport Carrier

When marker is folded, the second section should be cen-

tered in transport-carrier saddle and parallel with top of

drill box.

To adjust front-to-rear position of saddle, loosen 1/2-by-6-

inch u-bolts (1) that fasten transport-carrier mount onto

box frame. Slide transport-carrier assembly forward or

back as needed.

To adjust height of saddle, loosen 1/2-by-2-inch u-bolts (2)

that hold carrier tube to mounting bracket. Slide carrier

tube up or down as needed. Refer to Figure 3-14.

Figure 3-14

Marker Transport Carrier

15632