Marker chain disk adjustment – Great Plains 2420 Operator Manual User Manual

Page 25

23

Section 3 Adjustments

5/15/06

2400, 2410 and 2420 Three-Point Drill 118-706M

Great Plains Mfg., Inc.

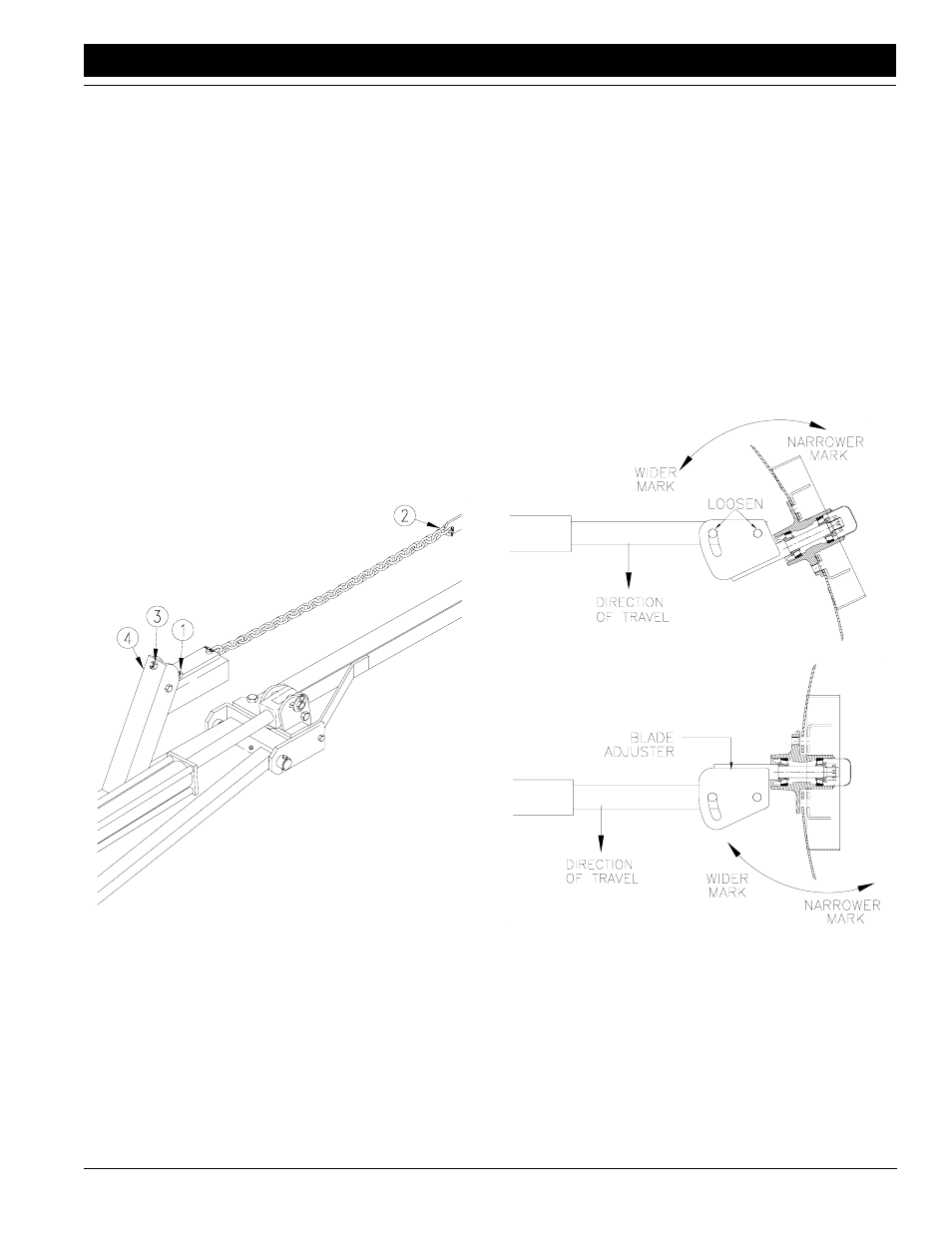

Marker Chain

There are two interrelated adjustments for the marker

chain. Make these adjustments in the following order. Re-

fer to Figure 3-15.

1.

Lifting Slack. With marker unfolded, back full-thread-

ed adjustment bolt (1) down until head extends as little

as possible. Slowly fold marker while observing disk. If

marker disk slides across ground more than a foot be-

fore chain and linkage lifts it up, the chain is too long.

Shorten chain one or two links by moving clevis (2).

Check adjustment by repeating folding process.

If chain is too short when marker is unfolded, it will

prevent end of marker from dropping into field depres-

sions, causing skips in your marker line. Correct this

condition by lengthening chain one or two links at cle-

vis (2).

2.

Folding Slack. Fold marker. Use full-threaded adjust-

ment bolt (1) to take slack out of chain while marker is

folded. Extend bolt until there is no chain slack. Lock

bolt in this position by tightening nuts (3) on either side

of upright channel (4).

Figure 3-15

Marker Chain Adjustment

15669

Disk Adjustment

There are two ways you can change the mark left by the

marker disk. Refer to Figure 3-16.

1.

Disk Angle. To change angle of cut, loosen 1/2-inch

bolts holding disk assembly. Rotate disk assembly as

desired.

2.

Direction of Cut. To change direction of cut and throw

dirt either in or out:

a.

Reverse blade and depth band by remounting lug

bolts on disk hub.

b.

Reverse angle of assembly by removing two 1/2-

inch bolts holding disk assembly. Turn disk as-

sembly one-half turn. Reinstall 1/2-inch bolts and

set disk angle.

Figure 3-16

Disk Blade Adjustments

11757

11248