Drive speed range sprockets, Transmission sprockets, Drive speed range sprockets transmission sprockets – Great Plains YP1625 Material Rate User Manual

Page 9: Driving, Driven

Great Plains Mfg., Inc.

5

11/23/2011

401-263B

4.

Before setting the planting rate, rotate the contact

wheel (it turns in the opposite direction from the main

tire). Check that seed meters, seed tubes, and drives

are working properly and free from foreign material.

Check that tire pressure is set according to the

“Specifications and Capacities” in your Operator’s

manual.

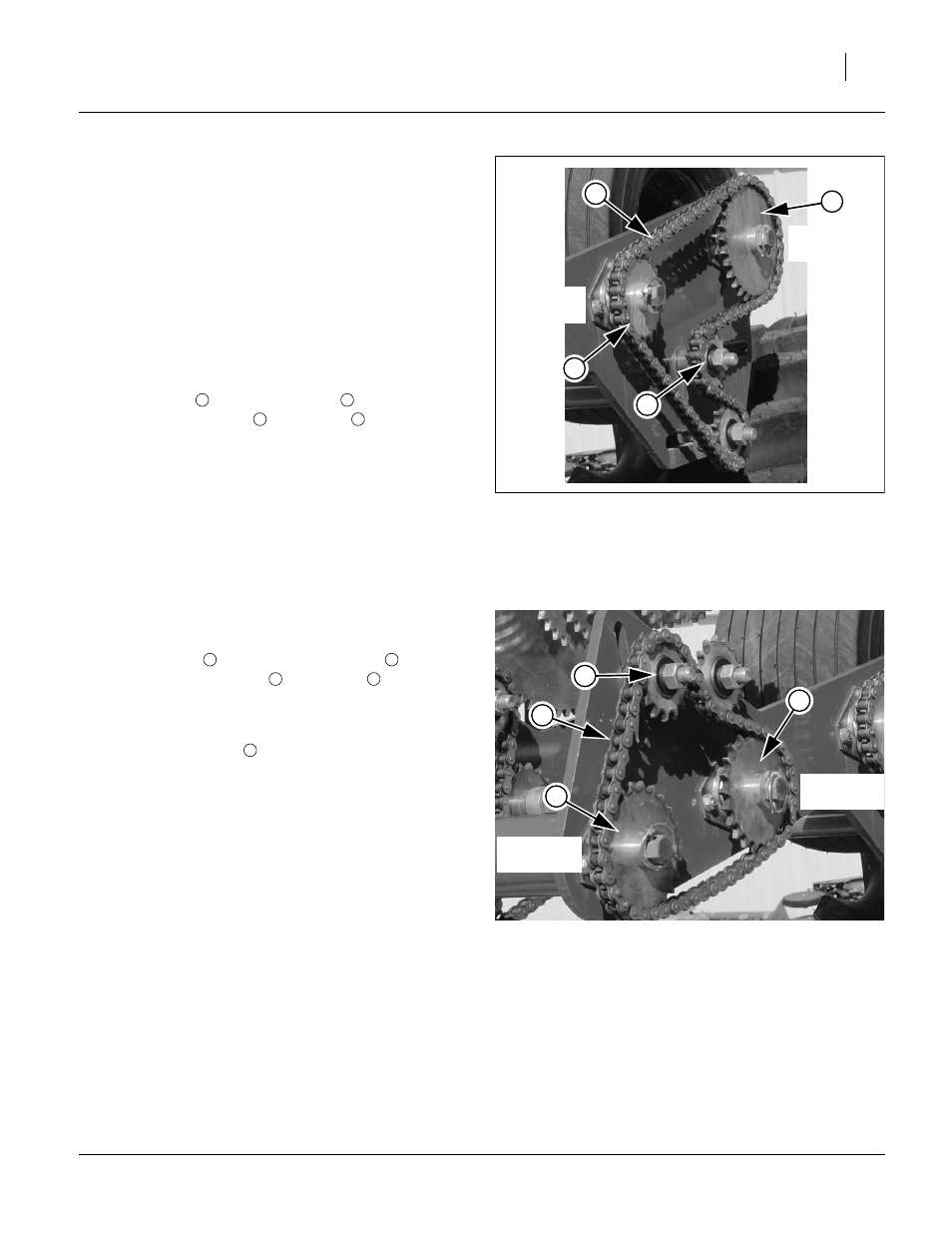

Drive Speed Range Sprockets

5.

Select the correct drive speed range sprockets for

your seed from the “Seed Rate Charts,” starting on

page 30.

Loosen idler

and remove chain

. Remove retain-

ing pins from Driving

and Driven

install speed range sprockets as necessary.

Note: Make sure the correct sprockets have been in-

stalled in the DRIVING and DRIVEN locations as

shown.

Reroute chain over sprockets and idlers as shown.

Move idler into chain so chain has

1

⁄

4

in (6mm) slack

in its longest span. Tighten idler and install lynch

pins.

Transmission Sprockets

Loosen idlers

and remove drive chain

. Remove

lynch pins from Driving

and Driven

rearrange driving and driven sprockets as necessary.

Reroute drive chain over sprockets and idlers as

shown. Move idlers

1

⁄

4

in

(6mm) slack in its longest span. Tighten idlers and

install lynch pins.

7.

Repeat step 5 and step 6 for the other contact

wheel.

8.

Switch the seed monitor from Setup/Configuration

mode to Operate mode. Load seed. Move the planter

to the field.

Null4:

1

4

3

2

Null4-AAC:

DRIVING

Null4-AAC:

DRIVEN

Null4:

Figure 5

Drive Speed Range

Sprockets Adjustment

21974

Null4:

Figure 6

Transmission Sprockets Adjustment

21974

4

Null4-AAC:

DRIVEN

Null4-AAC:

DRIVING

1

2

3