Setting relief valve, Strainer – Great Plains YP1625 Material Rate User Manual

Page 62

Great Plains Mfg., Inc.

58

401-263B

11/23/2011

Setting Relief Valve

A relief valve is mounted directly above the pump to pro-

tect the manifold and pump from excessive pressure.

Any product that dumps over the relief valve will dis-

charge from the dump line

To set relief valve:

Unlock plastic jam nut

from relief valve knob

2.

Unscrew knob clockwise until it loses contact with

internal spring.

3.

Screw knob counterclockwise two turns. Start at this

setting.

4.

Observe manifold gauge

. Watch for relief valve

discharge

while operating in the field.

5.

If valve is dumping product and gauge reads under

65 psi, stop tractor and, looking down, turn knob

clockwise

1

⁄

4

turn. Continue operating at normal field

speed. Repeat this step as needed until no product

is discharged from relief valve.

6.

If pressure gauge reads above 65 psi, change to a

larger orifice. Go to step 2. Repeat steps.

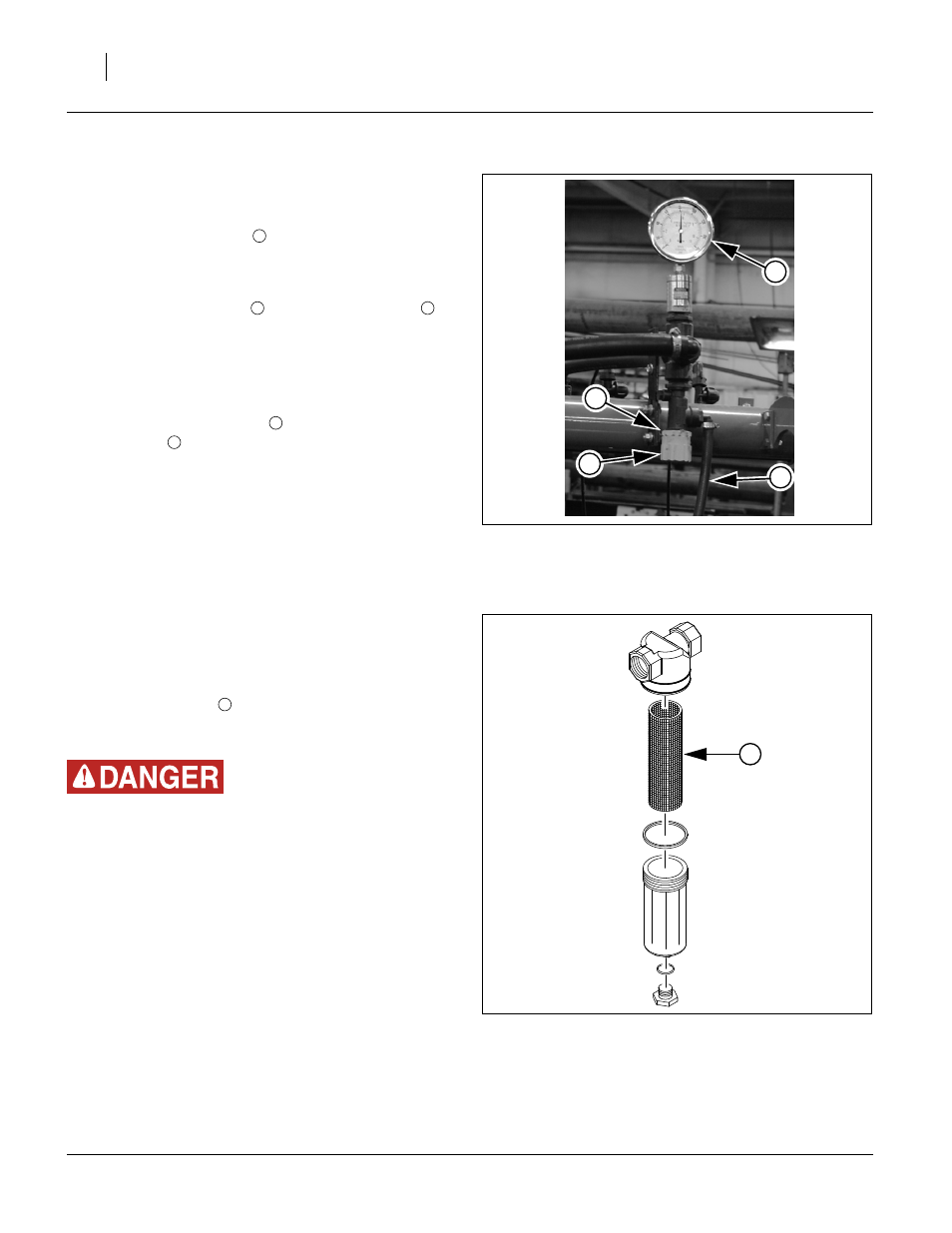

Strainer

Refer to Figure 20

A Banjo brand strainer is supplied with the fertilizer pump

option. It is plumbed before the Hypro pump. The stan-

dard 80 mesh screen

should be suitable for most

applications. Other screen sizes are available from Banjo

Corporation.

Wear protective gloves when changing screens.

If changing screen sizes, keep in mind the following.

• A smaller mesh (100) will keep very small manifold ori-

fice plates from plugging so often. However, the

screen will have to be cleaned more often.

• A larger mesh (50) or (30) will pass more material but

should only be considered when using large manifold

orifice plates.

• A plugged or partially plugged screen will starve the

pump resulting in a reduced application rate.

• Mesh sizes: (Smallest) 100, 80, 50, 30 (Largest)

Figure 19

Pressure Relief Valve

28029

2

3

4

1

1

3

4

Figure 20

Strainer

18418

5

5