Section 6 maintenance & lubrication, Maintenance fertilizer unit storage lubrication, See “lubrica – Great Plains EWNT7 1523Q-1630Q Operator Manual User Manual

Page 28: Tion” on, Lubrication, Lubrication symbols, Maintenance, Fertilizer unit, Storage

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M-A

4/25/06

26

Great Plains Mfg., Inc.

Section 6 Maintenance & Lubrication

4.

Feed cup drive sprocket hub should be oiled in its

square bore. Squirt oil on to the square feed cup

shaft and move feed cup adjustment lever back and

forth in order to get the oil back into the square. This

is most important before putting the drill in storage.

5.

Store the drill inside if possible for longer drill life.

6.

When in storage, lower the drill with openers on a

board or hard surface. Apply a light coat of oil to ex-

posed cylinder rods.

Lubrication

Lubrication is required every 50 hours of operation.

Use a multipurpose spray lube. Use as required.

Do not over lubricate.

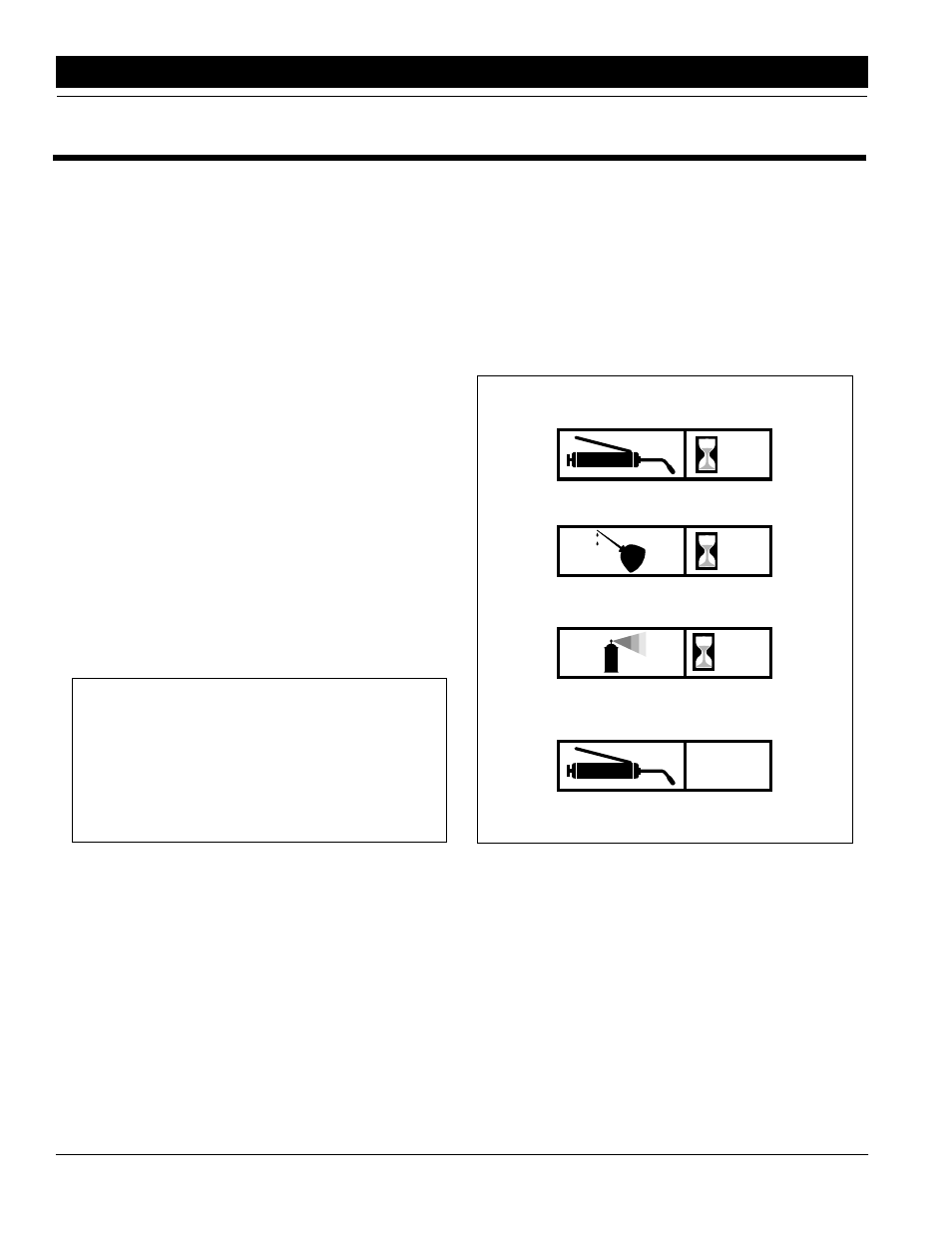

Lubrication Symbols

As

Required

Seasonally

50

Lubrication is required ____.

Lubrication is required every 10 hours of operation.

10

Maintenance

Proper servicing and adjustment is the key to the long

life of any farm implement. With careful and systematic

inspection, you can avoid costly maintenance, time and

repair.

1.

After using your drill for several hours, check all bolts

to be sure they are tight.

2.

Adjust idlers to remove excess slack from chains.

Clean and use chain lube on all roller chains as

needed.

3.

Feed cup drive sprocket should be oiled in its square

bore. Move feed cup adjustment lever away from the

sprocket as far as possible in order to get the oil back

into the square.

4.

Always maintain the proper air pressure in the rib

implement tires.

5.

Disk scrapers should be kept properly adjusted.

6.

Replace any worn, damaged or illegible safety de-

cals by obtaining new decals from your Great Plains

Dealer.

Fertilizer Unit

It is recommended that the fertilizer unit be thoroughly

cleaned every two or three days during operating sea-

son and before putting the drill in storage for an extend-

ed period of time.

Storage

1.

Clean the drill as necessary. Be sure that the seed

boxes are completely cleaned before storing.

2.

Lubricate and adjust all roller chains.

3.

Lubricate all pivots as indicated in the following Illus-

trations.

NOTE: Fertilizer build up on the rotor will affect the

fertilizer application rate. Drop fertilizer tray doors by

releasing latches on back of tray. Using a high-pres-

sure water system, thoroughly clean the fertilizer

tray, gate openings, and rotor. Rotate end sprocket

to ensure cleaning the entire fertilizer metering star

at each drop location.

Section 6

Maintenance & Lubrication