Native grass drive, Native grass rate, Native grass seeding adjustments – Great Plains EWNT7 1523Q-1630Q Operator Manual User Manual

Page 22

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M-A

4/25/06

20

Great Plains Mfg., Inc.

Section 4 Adjustments

Native Grass Drive

Native grass metering is directly related to the revolu-

tions of the clutch shaft per acre. The different sprocket

combinations are required to give a broad range of plant-

ing rates. The sprocket changes are made at the left end

of the drill, inside the double wall end panel. For native

grass seeding rates and sprocket combinations, refer to

page 21.

Native Grass Rate

Great Plains End Wheel No-Till Native Grass Drill has a

partition dividing the seed and native grass compart-

ments. Capacity of the seed box is 1.3 bushels per foot,

and the capacity of the native grass box is 1.2 bushels

per foot.

If the native grass is not being used, remove the chain

from the native grass drive sprocket to eliminate wear on

the native grass drive system.

Native Grass Seeding Adjustments

1.

Rotate the drive wheel to see that the feed cups and

drive are working properly and are free from foreign

matter

NOTE: Seeding rates vary greatly with variations in

types of seeds being drilled. The seed rate chart on

the following page is based on a seed mix of 5.7# of

pure live seed per 11.1# of bulk. The pure live seed

mix was Big Blue-1.5#, Little Blue-.8#, Side Oats

Grama-.6#, Western Wheat Grass-1#, Switch

Grass-.3#, and Indian Grass-1.5#. Factors which af-

fect seeding rates are: weight of seed, size of seed,

relative humidity and moisture content of the seed it-

self, ratio of inert material to seed, different propor-

tions of seed types affecting density, and tire

configuration, pressure and slippage. We recom-

mend that you test and adjust your drill using

the procedures listed below to help insure an ac-

curate seeding rate.

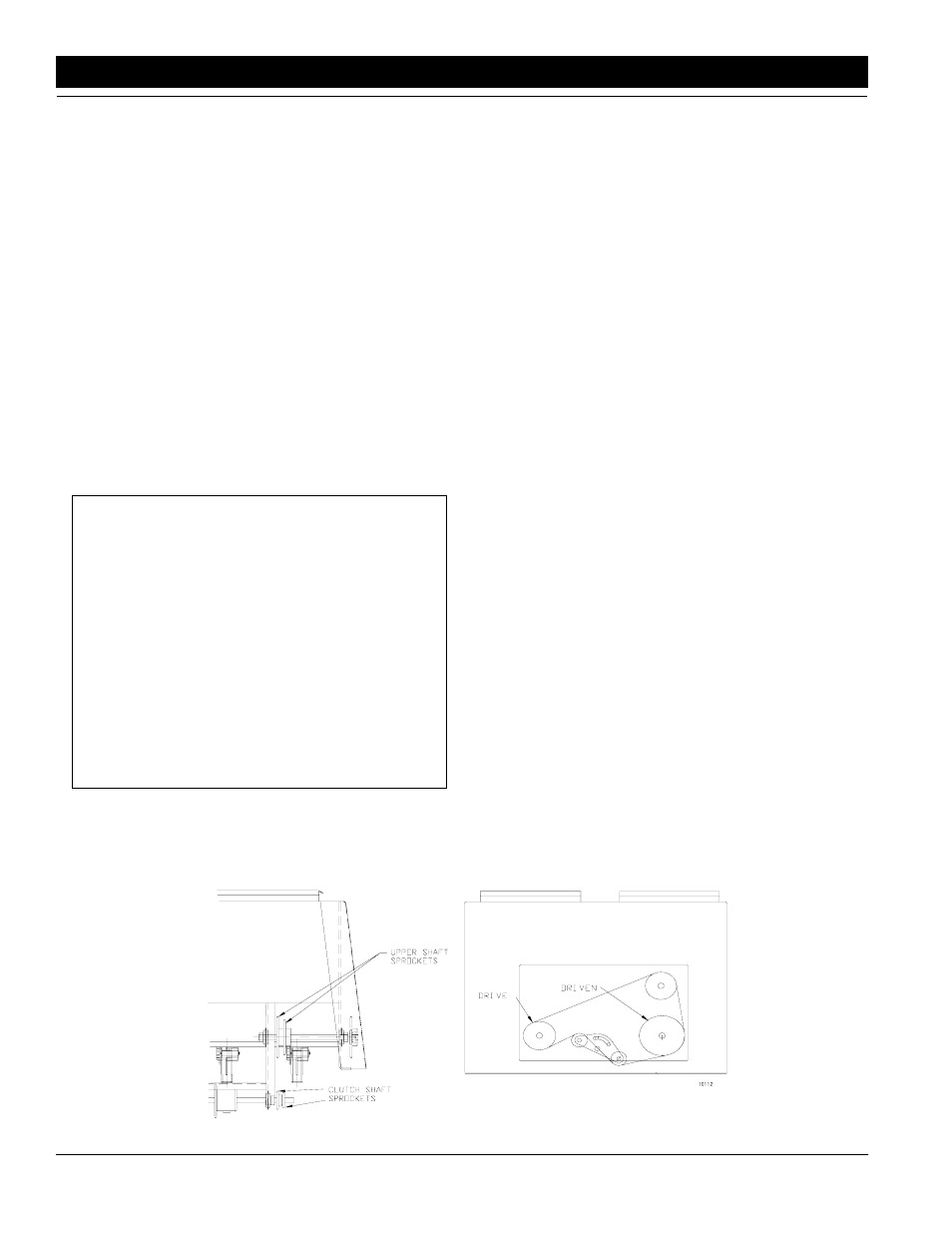

Refer to Figure 4-8:

2.

To adjust you seeding rate, first find the row spacing

and the desired pounds/acre on the native grass

seed rate chart {see "Seeding Chart"}. Determine

which sprocket combination is required for the clutch

shaft sprocket and the upper shaft sprocket. This

sprocket combination is designated by the drive

types A, B, D, and D. From the chart, choose the

driver and driven sprocket combination that will de-

liver the desired native grass seed rate. In order to

change sprockets on the native grass unit, loosen

the idler arm and remove the chain, remove the

lynch pins on the driver and driven sprockets and re-

arrange the sprockets accordingly.

3.

The pounds-per-acre in the seed chart is based on

drills having 9.00 x 24 drill rib tires.

4.

After setting up your sprocket arrangement, com-

plete the following procedure to calibrate the drill for

your specific seed type.

a.

Fill three or more compartments at least one-

half full of seed at the outboard end of the drill.

b.

Pull the seed tubes off the openers under the

compartments.

c.

Lower the drill hydraulically to planting position

in order to activate the clutch.

d.

Raise the drive (left) end tire off the ground us-

ing jack.

e.

Place a container under the seed tubes to gath-

er the seed as it is metered

f.

Rotate the tire until one acre has been tallied on

the acremeter. This will be approximately 422

rotations on a 10’ End Wheel No-Till Drill; and

592 rotations on a 7’ End Wheel No-Till Drill. Be

sure to check that the feeder cups have plenty of

seed coming into them.

g.

Weigh the seed which has been metered. Di-

vide by the number of cups that were metered.

This will give you the ounces/pounds metered

by each feed cup. Multiply by the number of

openers on your drill to arrive at the total

10112

Sprocket Arrangement Diagram

Figure 4-8

11837