Section 4 adjustments, Drive system clutch drive train operation, Drive system clutch – Great Plains EWNT7 1523Q-1630Q Operator Manual User Manual

Page 13: Drive train operation

-

11

4/25/06

Great Plains Mfg., Inc.

Section 4 Adjustments

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M-A

Drive System Clutch

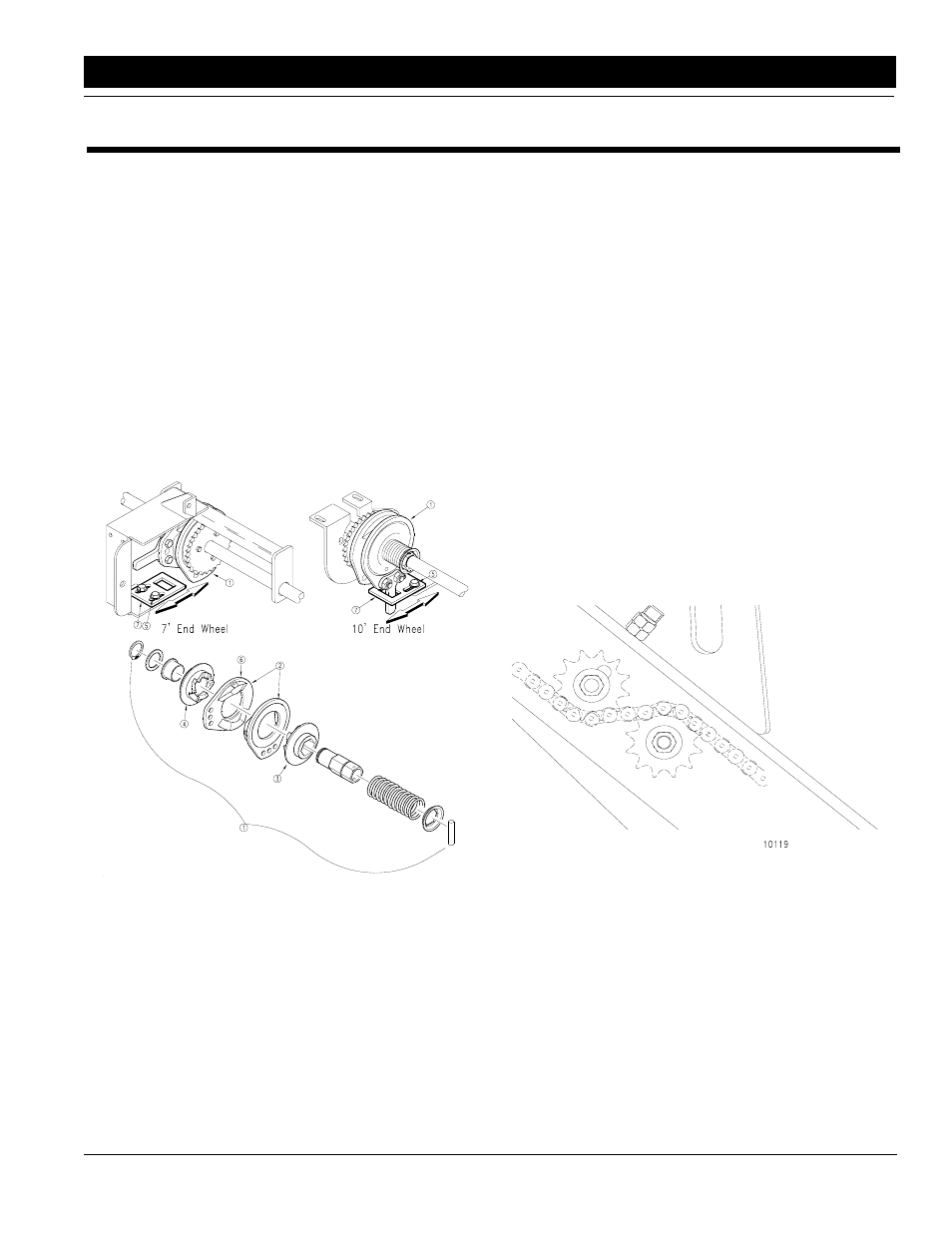

Refer to Figure 4-1:

The main drive clutch (#1) on your drill is a mechanical

release - jaw style design which may require some ad-

justments before using your drill. Raise the drill to the

transport position. Check between the two cam plates

(#2) which disengage the jaws (#3) & (#4) of the clutch

halves. The clutch jaws (#3) & (#4) should be completely

separated at this point.

Adjustments can be made to the cam plate (#6) by loos-

ening the bolts, and nuts (#5) in the clutch tab(#7).

Whenever adjusting the clutch, check to be sure the

clutch jaws (#3) & (#4) are engaged completely when

the drill is lowered to the field position. The clutch jaws

(#3) & (#4) should also be completely disengaged when

the drill is raised for transport.

Jaw Clutch Adjustment

Figure 4-1

14018

Drive Train Operation

Refer to Figure 4-2:

Your grain drill uses standard no. 40 roller chain through

out its drive system. The drive system is simple and de-

signed for low maintenance. All chain idlers should be

checked at the beginning of each season to insure that

they are adjusted properly.

To do a maintenance inspection, simply check each idler

to insure that it is taking up any excess chain slack. On

fertilizer and native grass drills the inspection cover for

the drive is located on the outside of the left box end pan-

el and this cover must be removed to inspect the fertilizer

and native grass drive chain and idler.

In the left wheel arm are two idler sprockets, Figure 4-2,

which should be readjusted after the first 100 acres of

drill use and then at the beginning of each season. To

adjust, move the front idler sprocket, on the top of the

chain, down, by loosening the jam nut and screwing the

adjustment stud in. Chain idlers should always be kept

snug against the slack side of the chain. Do not over

tighten chains, it will cause excessive wear on idlers and

drive components. Retighten the jam nut to maintain the

idler position.

10119

Idler Sprocket Adjustments

Figure 4-2

Section 4

Adjustments