Assembly, Install hitch assembly, Install k-flex shanks – Great Plains 8560 FCF Predelivery Manual User Manual

Page 11: Install hitch assembly install k-flex shanks

02/10/2014

560-484Q

Great Plains Manufacturing, Inc.

7

Assembly

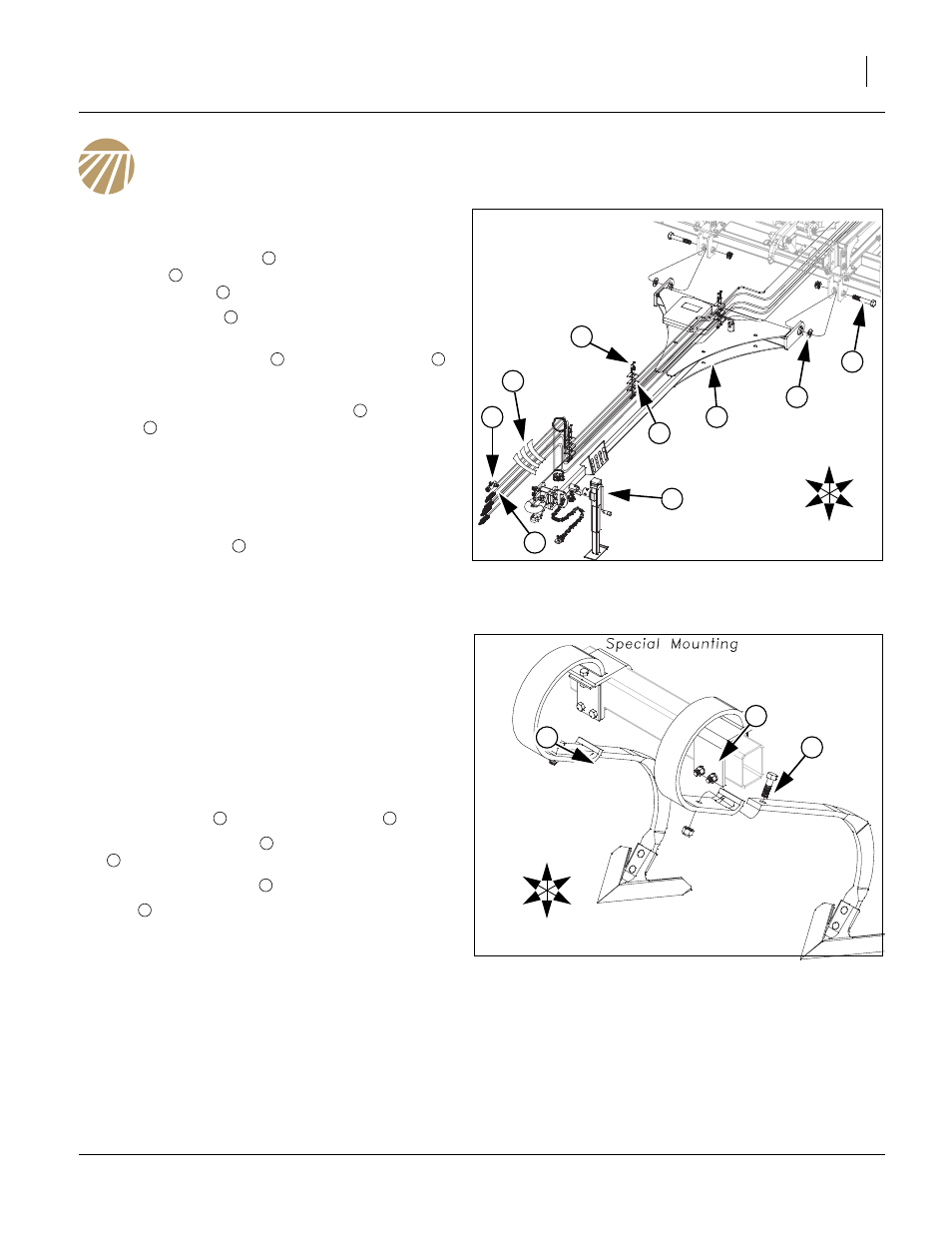

Install Hitch Assembly

Refer to Figure 3

23. Attach hitch assembly

to brace bar with 1 1/4 flat

washers

(one on outside of hitch, both sides), 1 1/

4 Gr. 8 hex bolt

and 1 1/4 top lock nut

24. Attach hitch jack

to front jack tube as shown to

support front of tongue.

25. Route 30’ light harness

and hydraulic hoses

(that are rolled up on front of brace bar), along hitch

assembly (close to threaded blocks) as shown.

Secure with stackable hose clamps

, 5/16 x 2 hex

bolts

(for three clamps, 5/16 x 1 1/4 for two clamps

or 5/16 x 5/8 for one clamp) and 5/16 lock washers.

Note: Position hoses in clamps to where they have

enough slack to go around ears on hitch and won’t

get pinch when hitch pivots when machine is raised

up and down.

26. Fasten hose wrap

around light harness and hoses

as shown.

27. Bolts may be tightened to specs, See “Torque Val-

Install K-Flex Shanks

Refer to Figure 4

28. If machine is equipped with magnum shanks, See

“Install Magnum Shanks” on page 8.

29. The shank mounts will be shipped in correct location

from factory. If something got moved during shipping,

go to layout section of “Operator’s Manual” for proper

placement.

30. Locate shank assemblies from misc. box and remove

the 5/8 x 2 bolt

from shank assembly

.

31. Slide shank assembly

through slot in shank mount

and align holes as shown below.

32. Re-attach 5/8 x 2 bolt

, secure with 5/8 lock nut.

33. Bolt

may be tightened to specs, See “Torque Val-

34. Repeat same procedure for rest of shanks.

Figure 3

Hitch

41887

9

5

1

2

6

7

8

U

D

F

B

L

R

4

3

1

2

3

4

5

6

7

8

9

Figure 4

K-Flex Shank

41633

1

2

3

U

D

F

B

L

R

1

2

2

3

1

1