Machine cleaning, Tire pressure check, Wheel bearings repack – Wheatheart Swing Away Auger (10 & 13) User Manual

Page 32: Wheel bolt tightening, Cable tightening

5. M

AINTENANCE

W

HEATHEART

- SA A

UGERS

5.3. M

AINTENANCE

P

ROCEDURES

SA 1061, 1071, 1081, 1091, 1371, 1381, 1391

32

30582 R7

2. Make sure the gearbox is half full (center of cross shaft) and free of foreign

objects. Gearbox should be level when checking or refilling. Do not overfill.

5.3.8. M

ACHINE

C

LEANING

1. Clean out excess grain from auger tube, boot, and hopper.

2. Make sure water can drain from the auger tube and hopper and then wash

the tube with a water hose or pressure washer until all dirt, mud, debris, or

residue is gone.

3. Provide sufficient time for the water to drain from the auger.

5.3.9. T

IRE

P

RESSURE

C

HECK

With a tire pressure gauge, check each tire to make sure it is between 18–24 psi

(124 - 165 kPa).

• Ensure tires are cold prior to checking pressure.

5.3.10. W

HEEL

B

EARINGS

R

EPACK

1. Remove the wheel bolts and the wheels.

2. Remove the wheel bearing and pack with grease. Refer to page 27 for

recommended grease.

5.3.11. W

HEEL

B

OLT

T

IGHTENING

1. Clean wheel and hub mounting

surfaces to ensure there is no rust or

debris.

1. Install

the

wheel

and finger-tighten the

wheel bolts. Inspect to make sure the

wheel is sitting flush with the hub.

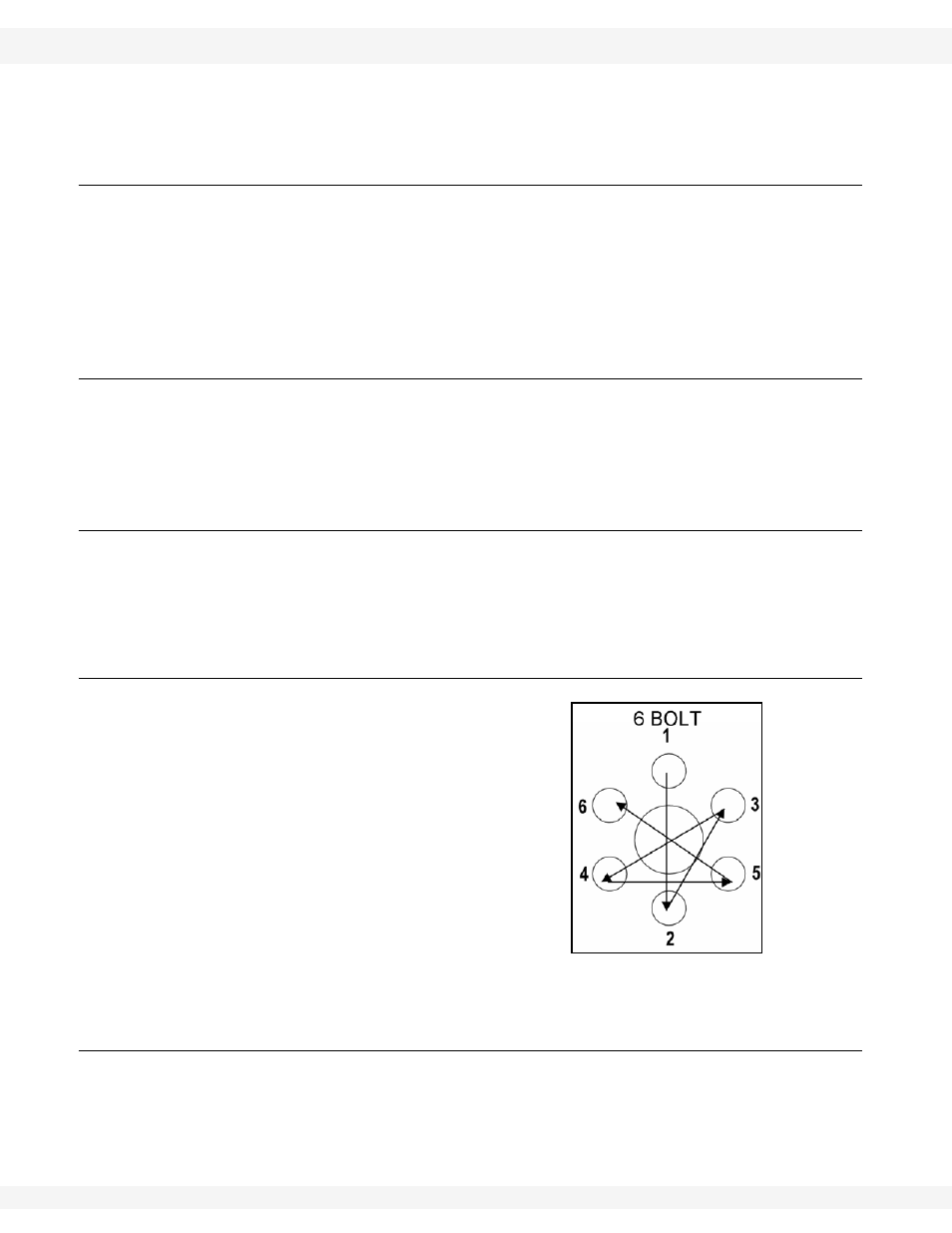

2. Tighten

the

wheel

bolts with a torque

wrench to 80 ft-lb (±10 ft-lb) of torque.

Tighten the wheel bolts in a diagonal

pattern as shown in Figure 5.6.

5.3.12. C

ABLE

T

IGHTENING

The cables are properly adjusted when:

• The tube is straight side-to-side.

• The discharge end is deflected sightly upwards.

Figure 5.6 Crisscross Pattern

Note: